Benefits of Using Reversed Bending Descaler for Industrial Equipment

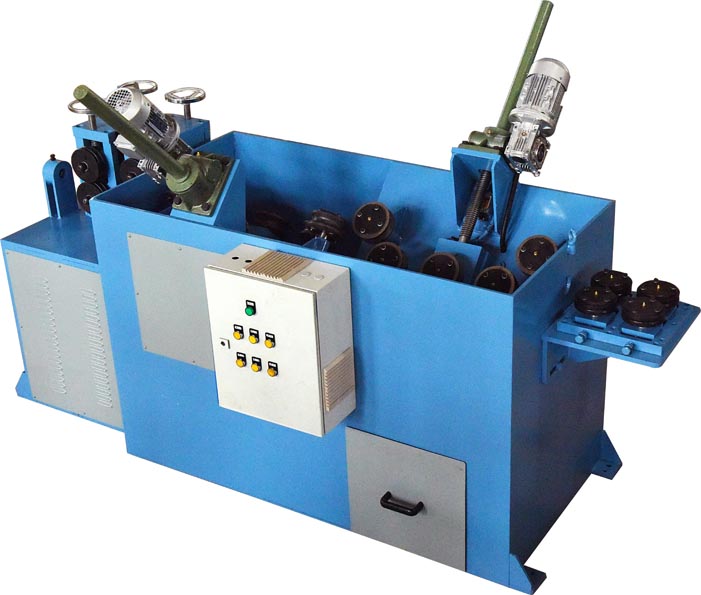

Industrial equipment is essential for the smooth operation of various industries, from manufacturing to energy production. However, over time, these machines can accumulate scale and deposits that can hinder their performance and efficiency. To combat this issue, many industries rely on descaling solutions to keep their equipment running smoothly. One popular descaling method is the Steel Brush Descaler for Wire Drawing Process, which offers several benefits for industrial equipment.

One of the main advantages of using a MECHANICAL DESCALERS is its ability to effectively remove scale and deposits from equipment. This descaling method involves passing a high-pressure water jet through a series of specially designed nozzles that create a reverse bending effect. This action helps to dislodge and remove scale and deposits from the inner surfaces of pipes, tubes, and other equipment, ensuring that they remain clean and free from obstructions.

In addition to its effectiveness, the Mechanical Wire Descaler is also a versatile descaling solution that can be used on a wide range of industrial equipment. Whether you need to descale heat exchangers, boilers, condensers, or other types of machinery, the Reversed Bending Descaler For Wire Drawing Prepration Process can provide the cleaning power you need. This versatility makes it a cost-effective solution for industries that rely on a variety of equipment to keep their operations running smoothly.

Another benefit of using a Wire Rod Descaling Machine is its ability to improve the efficiency and performance of industrial equipment. By removing scale and deposits that can impede the flow of fluids through pipes and tubes, the reversed bending descaler helps to optimize the operation of machinery, leading to increased productivity and reduced downtime. This can result in significant cost savings for industries that rely on their equipment to meet production targets and deadlines.

Furthermore, the Mechanical brush descaler is a safe and environmentally friendly descaling solution. Unlike traditional descaling methods that rely on harsh chemicals and abrasive materials, the reversed bending descaler uses only high-pressure water to clean equipment. This means that there are no harmful chemicals or pollutants released into the environment during the descaling process, making it a sustainable choice for industries that are committed to reducing their environmental impact.

Additionally, the mechanical descaling of wire drawing is easy to use and requires minimal maintenance, making it a convenient descaling solution for industrial facilities. With its simple design and user-friendly operation, the reversed bending descaler can be quickly deployed to clean equipment without the need for extensive training or specialized equipment. This can help to streamline maintenance processes and ensure that equipment remains in optimal condition for longer periods, reducing the need for costly repairs and replacements.

In conclusion, the Mechanical Descaling for wire drawing prepration process offers several benefits for industrial equipment, including effective scale removal, versatility, improved efficiency, safety, and ease of use. By choosing this descaling method, industries can ensure that their equipment remains clean and free from obstructions, leading to increased productivity, reduced downtime, and cost savings. With its environmentally friendly design and user-friendly operation, the Reversed Bending Descaler For Wire Drawing Prepration Process is a reliable and sustainable descaling solution for industries looking to maintain the performance and longevity of their equipment.