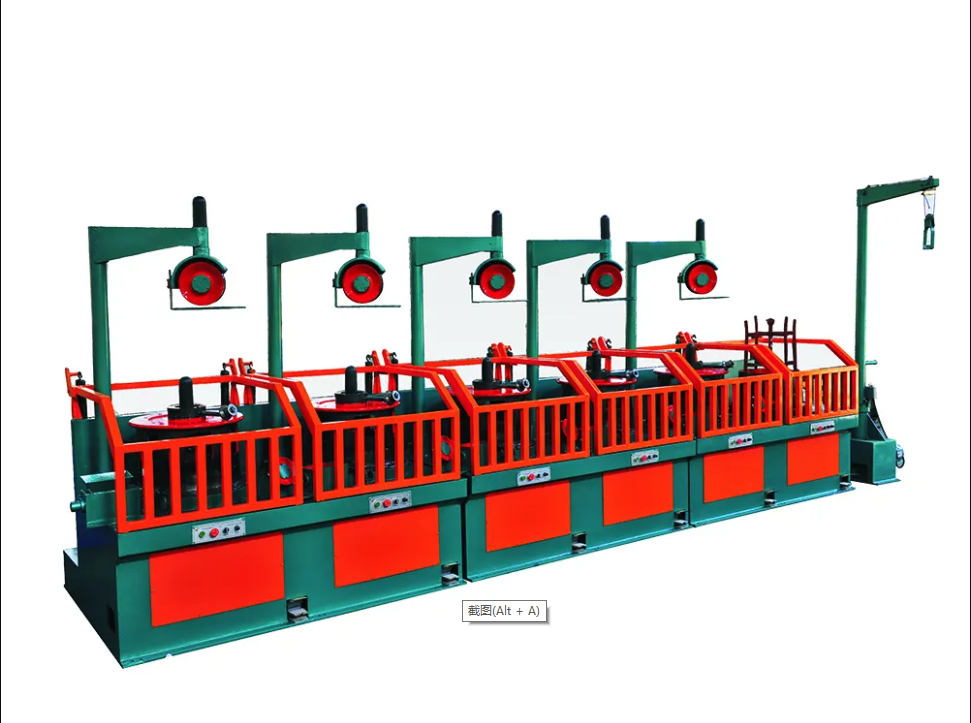

A continuous pulley wire drawing machine is a crucial piece of equipment in the wire manufacturing industry. This machine is used to draw wire through a series of dies to reduce its diameter and improve its quality. There are several benefits to using a continuous pulley wire drawing machine, which we will explore in this article.

One of the main advantages of using a continuous pulley wire drawing machine is its efficiency. This machine is capable of drawing wire at a high speed, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help companies meet tight production deadlines and fulfill customer orders quickly and efficiently.

In addition to its speed, a continuous pulley wire drawing machine also offers precision and consistency in wire drawing. The dies in the machine are designed to reduce the diameter of the wire gradually, ensuring that the final product meets the desired specifications. This level of precision is essential for industries that require high-quality wire for their products, such as the automotive or aerospace industries.

Another benefit of using a continuous pulley wire drawing machine is its versatility. These machines can be used to draw wire of various materials, including steel, copper, and aluminum. This versatility allows manufacturers to produce a wide range of wire products to meet the needs of different industries. Whether it’s fine wire for electronics or heavy-duty wire for construction, a continuous pulley wire drawing machine can handle the job.

Furthermore, a continuous pulley wire drawing machine is cost-effective in the long run. While the initial investment in this equipment may be significant, the savings in production costs over time can be substantial. By increasing efficiency, reducing waste, and improving quality, manufacturers can see a significant return on their investment in a continuous pulley wire drawing machine.

Additionally, using a continuous pulley wire drawing machine can help improve workplace safety. These machines are designed with safety features to protect operators from accidents and injuries. By automating the wire drawing process, workers can avoid potentially dangerous tasks and focus on other aspects of production. This can create a safer work environment and reduce the risk of workplace incidents.

Overall, the benefits of using a continuous pulley wire drawing machine are clear. From increased efficiency and precision to versatility and cost-effectiveness, this equipment offers numerous advantages for manufacturers in the wire industry. By investing in a continuous pulley wire drawing machine, companies can improve their production processes, meet customer demands, and stay competitive in the market.