Table of Contents

Benefits of Using a Wire Spooling Machine in Industrial Applications

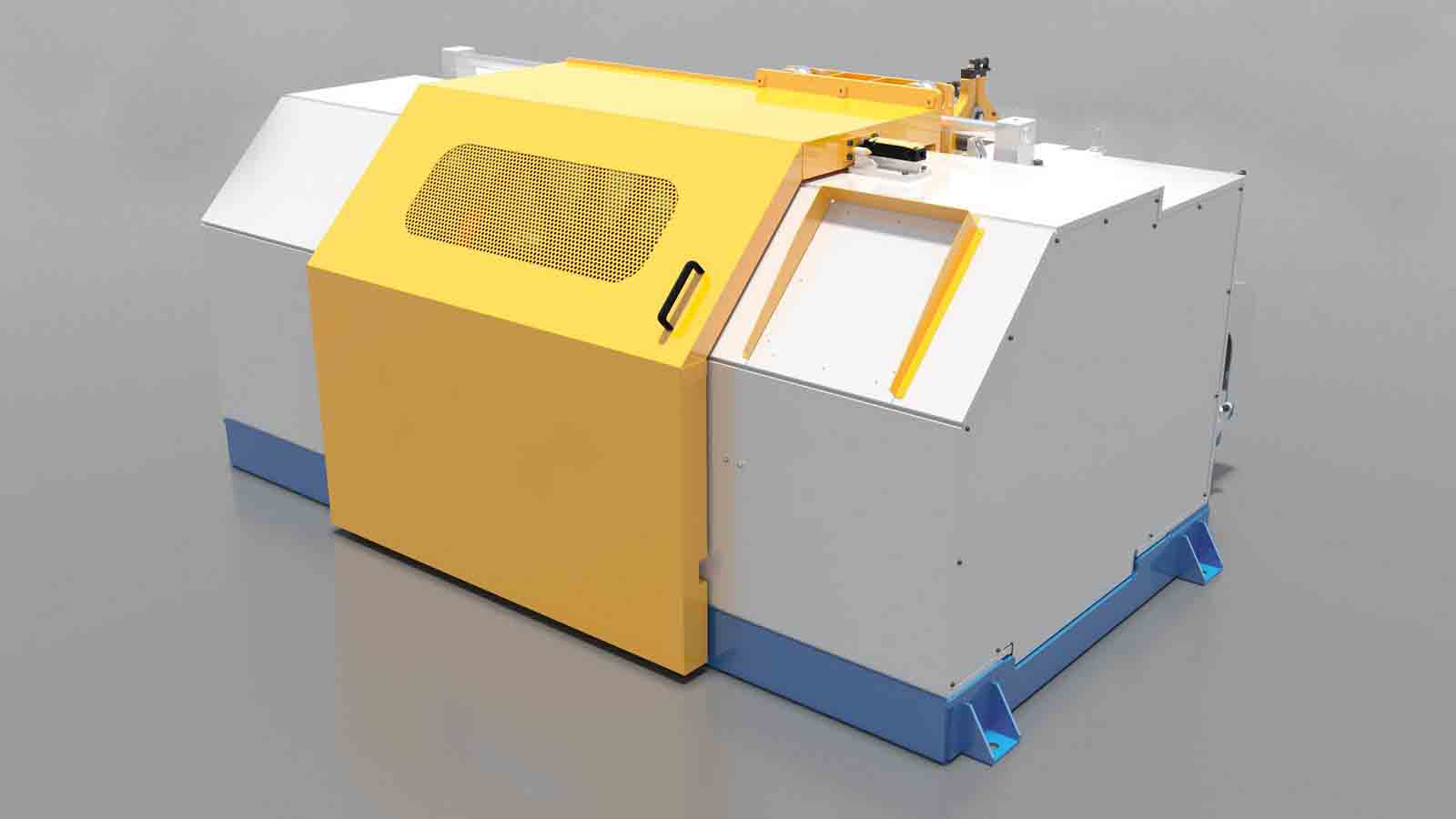

Wire spooling machines are essential tools in various industrial applications, providing numerous benefits that help streamline processes and improve efficiency. These machines are designed to wind wire onto a spool in a controlled and precise manner, making them ideal for industries that require the handling of large quantities of wire on a regular basis.

One of the key benefits of using a wire spooling machine is the ability to increase productivity. By automating the process of spooling wire, workers can focus on other tasks, leading to a more efficient workflow. This not only saves time but also reduces the risk of human error, ensuring that the wire is spooled correctly every time.

In addition to improving productivity, wire spooling machines also help to reduce waste. By spooling wire onto a spool, companies can minimize the amount of wire that is wasted during the handling process. This not only saves money but also helps to reduce the environmental impact of industrial operations.

Another benefit of using a wire spooling machine is the ability to customize the spooling process to meet specific requirements. These machines can be programmed to spool wire at different speeds and tensions, allowing companies to tailor the process to their exact needs. This level of customization ensures that the wire is spooled correctly and consistently, resulting in higher quality products.

Furthermore, wire spooling machines help to improve safety in the workplace. By automating the spooling process, workers are less likely to come into contact with moving machinery, reducing the risk of accidents and injuries. This not only protects employees but also helps to create a safer working environment overall.

Additionally, wire spooling machines are versatile tools that can be used in a wide range of industries. From manufacturing and construction to telecommunications and automotive, these machines are essential for companies that rely on wire for their operations. Whether spooling copper wire for electrical applications or steel wire for construction projects, these machines can handle a variety of wire types and sizes with ease.

Moreover, wire spooling machines are cost-effective investments for companies looking to improve their operations. While the initial cost of purchasing a machine may seem high, the long-term benefits far outweigh the upfront expense. By increasing productivity, reducing waste, and improving safety, these machines can help companies save money in the long run.

In conclusion, wire spooling machines offer numerous benefits for companies in various industries. From increasing productivity and reducing waste to improving safety and customization, these machines are essential tools for handling wire in industrial applications. By investing in a wire spooling machine, companies can streamline their operations, improve efficiency, and ultimately save money in the long run.

How to Properly Maintain and Troubleshoot a Wire Spooling Machine

Wire spooling machines are essential tools in various industries that deal with wires and cables. These machines are used to wind wire onto a spool or reel, making it easier to transport and store. Proper maintenance and troubleshooting of a wire spooling machine are crucial to ensure its optimal performance and longevity.

One of the most important aspects of maintaining a wire spooling machine is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to malfunctions and decreased efficiency. It is recommended to clean the machine after each use to prevent build-up and ensure smooth operation.

In addition to cleaning, lubricating the moving parts of the wire spooling machine is essential. Lubrication helps reduce friction between components, preventing wear and tear and prolonging the machine’s lifespan. It is important to use the appropriate lubricant for each part of the machine to avoid damage.

Regular inspection of the wire spooling machine is also necessary to identify any potential issues before they escalate. Check for loose or damaged parts, worn-out components, and signs of corrosion. Addressing these issues promptly can prevent costly repairs and downtime.

Another crucial aspect of maintaining a wire spooling machine is calibrating it regularly. Calibration ensures that the machine is operating at the correct speed and tension, resulting in consistent and accurate wire spooling. Follow the manufacturer’s guidelines for calibration to ensure optimal performance.

When troubleshooting a wire spooling machine, start by identifying the problem. Common issues include jammed wire, uneven winding, and motor malfunctions. Once the problem is identified, refer to the machine’s manual for troubleshooting steps.

If the wire spooling machine is jammed, carefully remove the tangled wire and inspect the components for any damage. Check for any obstructions in the wire path and ensure that the tension is set correctly. Restart the machine and monitor its operation to ensure the issue has been resolved.

Uneven winding can be caused by improper tension settings or misaligned components. Adjust the tension settings according to the wire specifications and realign any misaligned parts. Test the machine with a small amount of wire to ensure that the winding is even and consistent.

If the motor is malfunctioning, check the power source and connections to ensure they are secure. Inspect the motor for any signs of damage or overheating. If the motor needs to be replaced, contact the manufacturer for a replacement part and follow their instructions for installation.

In conclusion, proper maintenance and troubleshooting of a wire spooling machine are essential to ensure its optimal performance and longevity. Regular cleaning, lubrication, inspection, and calibration are key aspects of maintenance. When troubleshooting issues, identify the problem, refer to the manual for guidance, and address the issue promptly. By following these guidelines, you can keep your wire spooling machine in top condition and avoid costly repairs and downtime.