Benefits of Using a Flux Cored Welding Wire Surface Grease-Removing Machine

Flux cored welding wire surface grease-removing machines are essential tools in the welding industry. These machines are designed to efficiently remove grease and other contaminants from the surface of flux cored welding wire, ensuring a clean and smooth welding process. There are several benefits to using a flux cored welding wire surface grease-removing machine, which we will explore in this article.

One of the primary benefits of using a flux cored welding wire surface grease-removing machine is improved weld quality. Grease and other contaminants on the surface of welding wire can lead to poor weld quality, including porosity, cracking, and incomplete fusion. By removing these contaminants with a grease-removing machine, welders can ensure that their welds are strong, clean, and free from defects.

In addition to improving weld quality, flux cored welding wire surface grease-removing machines also help to increase productivity. Contaminated welding wire can cause welding equipment to malfunction, leading to costly downtime and delays in production. By using a grease-removing machine to clean welding wire before use, welders can prevent equipment malfunctions and keep production running smoothly.

Another benefit of using a flux cored welding wire surface grease-removing machine is increased safety. Grease and other contaminants on welding wire can create hazardous fumes and smoke when heated during the welding process. By removing these contaminants with a grease-removing machine, welders can reduce the risk of exposure to harmful fumes and create a safer working environment.

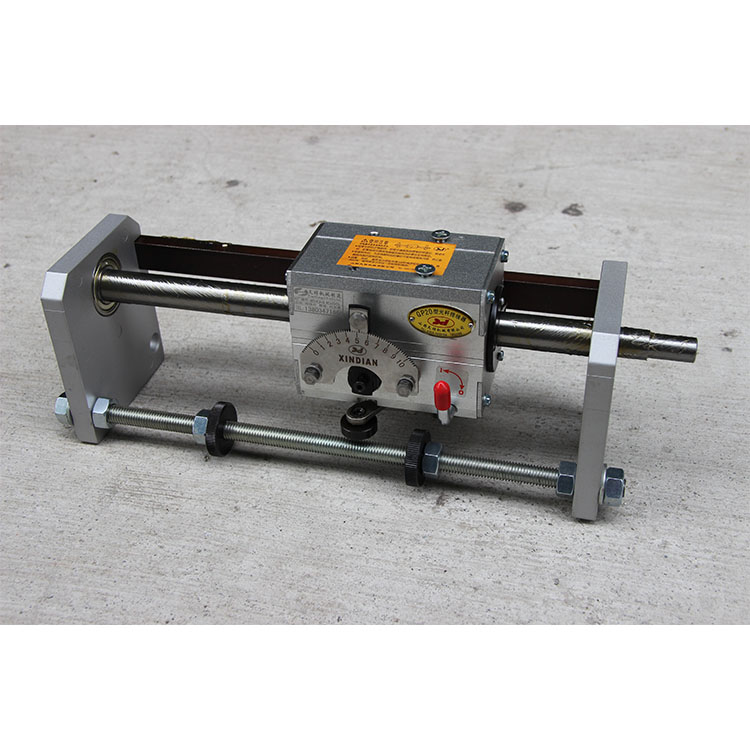

Furthermore, flux cored welding wire surface grease-removing machines are easy to use and require minimal maintenance. These machines are designed to be user-friendly, with simple controls and easy-to-follow instructions. Additionally, most grease-removing machines are built to last, with durable construction and high-quality components that require little maintenance over time.

Using a flux cored welding wire surface grease-removing machine can also help to extend the life of welding equipment. Contaminated welding wire can cause excessive wear and tear on welding equipment, leading to costly repairs and replacements. By cleaning welding wire with a grease-removing machine, welders can prolong the life of their equipment and save money in the long run.

Overall, the benefits of using a flux cored welding wire surface grease-removing machine are clear. These machines improve weld quality, increase productivity, enhance safety, and extend the life of welding equipment. By investing in a grease-removing machine, welders can ensure that their welds are clean, strong, and free from defects, leading to better results and a more efficient welding process.