Table of Contents

How To Properly Maintain And Troubleshoot Rolling Ring Drive Systems

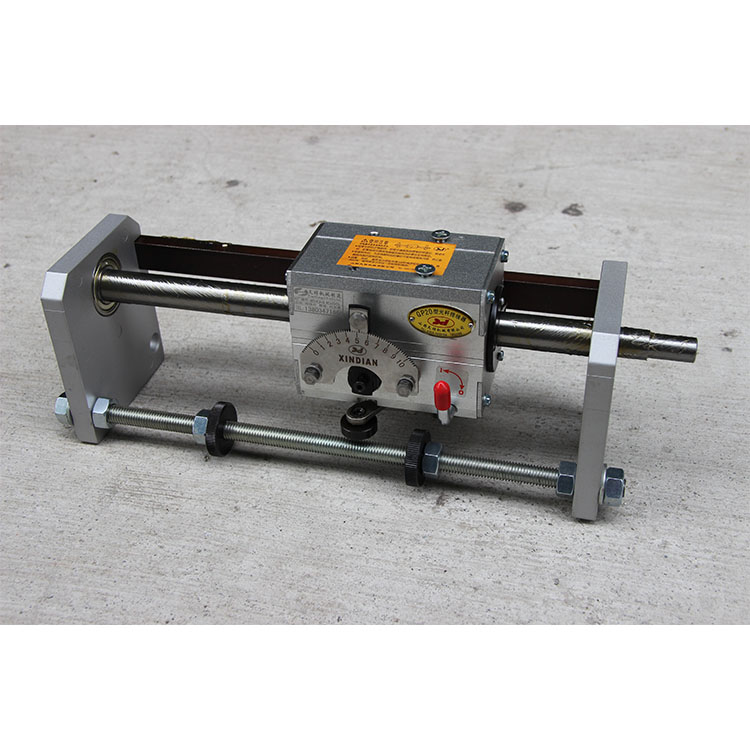

Rolling ring drives are a type of mechanical drive system that is commonly used in various industrial applications. These drives are known for their simplicity, reliability, and efficiency. However, like any mechanical system, rolling ring drives require proper maintenance and occasional troubleshooting to ensure optimal performance and longevity.

One of the key components of a rolling ring drive system is the rolling ring itself. The rolling ring is a precision-engineered metal ring that is designed to grip and drive a shaft or rod. Over time, the rolling ring can wear out due to friction and stress, leading to decreased performance and potential failure. To prevent this, it is important to regularly inspect the rolling ring for signs of wear and tear.

When inspecting the rolling ring, look for any signs of deformation, cracks, or excessive wear. If any of these issues are present, it is important to replace the rolling ring immediately to prevent further damage to the drive system. Additionally, make sure to lubricate the rolling ring regularly to reduce friction and prolong its lifespan.

Another important aspect of maintaining a Rolling Ring Traverse Drive system is ensuring proper alignment of the drive components. Misalignment can cause excessive wear on the rolling ring and other components, leading to decreased performance and potential failure. To prevent this, regularly check the alignment of the drive components and make any necessary adjustments.

In addition to regular maintenance, it is also important to troubleshoot any issues that may arise with a rolling ring drive system. One common issue that can occur is slippage of the rolling ring on the shaft or rod. This can be caused by a variety of factors, such as improper tension, misalignment, or worn-out components.

To troubleshoot slippage issues, first check the tension of the rolling ring. If the tension is too loose, tighten it to ensure proper grip on the shaft or rod. Additionally, check for any signs of misalignment or worn-out components that may be causing the slippage. If necessary, make any adjustments or replacements to resolve the issue.

Another common issue that can occur with rolling ring drives is excessive noise during operation. This can be caused by a variety of factors, such as worn-out components, misalignment, or lack of lubrication. To troubleshoot noise issues, first inspect the drive components for any signs of wear or damage. If necessary, replace any worn-out components and lubricate the drive system to reduce friction and noise.

In conclusion, proper maintenance and troubleshooting are essential for ensuring the optimal performance and longevity of rolling ring drive systems. By regularly inspecting and maintaining the rolling ring and drive components, as well as troubleshooting any issues that may arise, you can prevent costly downtime and ensure the co

Advantages Of Using Rolling Ring Drive In Industrial Applications

Rolling ring drives are a type of mechanical drive system that is commonly used in industrial applications. They consist of a rolling ring that is driven by a rotating shaft, which in turn drives a driven shaft. This type of drive system is known for its simplicity, reliability, and efficiency, making it a popular choice for a wide range of industrial applications.

One of the key advantages of using a rolling ring drive in industrial applications is its high efficiency. Unlike other types of drive systems, such as belt drives or chain drives, rolling ring drives have very little slippage, which means that more of the input power is transferred to the output shaft. This high efficiency makes rolling ring drives ideal for applications where precise control and high power output are required.

Another advantage of rolling ring drives is their compact size. Because they do not require large pulleys or sprockets like belt or chain drives, rolling ring drives can be much smaller and more compact, making them ideal for applications where space is limited. This compact size also makes rolling ring drives easier to install and maintain, saving time and money in the long run.

Rolling ring drives are also known for their reliability. Because they have fewer moving parts than other types of drive systems, there is less chance of mechanical failure or breakdown. This reliability makes rolling ring drives ideal for applications where downtime is not an option, such as in manufacturing or production environments.

In addition to their efficiency, compact size, and reliability, rolling ring drives are also highly customizable. They can be easily adapted to suit a wide range of applications, from simple conveyor systems to complex robotic arms. This flexibility makes rolling ring drives a versatile choice for a wide range of industrial applications.

One of the key features of rolling ring drives is their ability to provide precise control over speed and torque. By adjusting the tension on the rolling ring, operators can easily control the speed and torque of the driven shaft, allowing for precise control over the movement of machinery or equipment. This level of control is essential in many industrial applications, where precise movement and positioning are required.

Overall, rolling ring drives offer a number of advantages for industrial applications. Their high efficiency, compact size, reliability, and flexibility make them an ideal choice for a wide range of applications. Whether you need precise control over speed and torque, or simply need a reliable and efficient drive system, rolling ring drives are a versatile and cost-effective solution for your industrial needs.