Table of Contents

How to Properly Maintain and Troubleshoot Horizontal Wire Spooler Machine

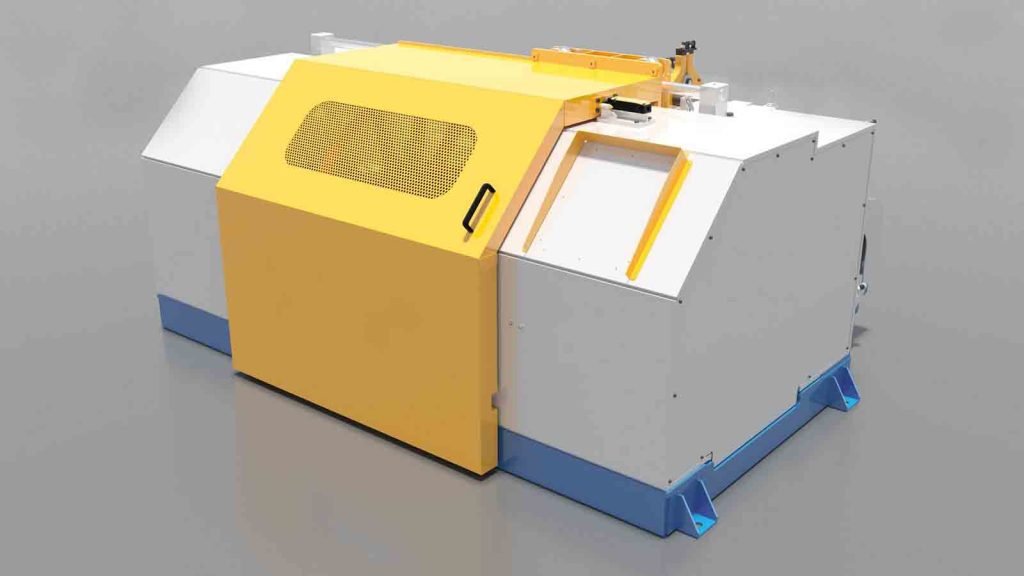

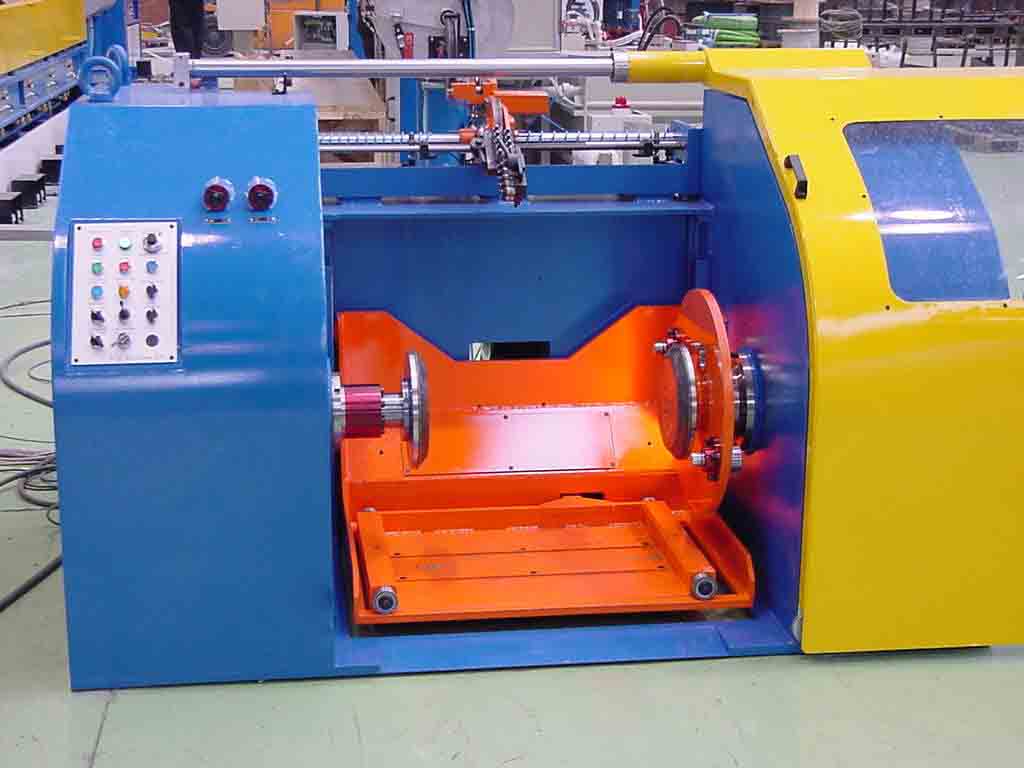

Horizontal wire Respooling Machine is essential equipment in various industries that deal with wire processing and manufacturing. These machines are used to wind wire onto spools in a horizontal orientation, making the process more efficient and streamlined. Proper maintenance and troubleshooting of these machines are crucial to ensure their optimal performance and longevity.

To properly maintain a horizontal wire spooler machine, regular cleaning and lubrication are key. Dust, debris, and other contaminants can accumulate on the machine’s components, leading to decreased efficiency and potential malfunctions. It is important to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating moving parts with the appropriate lubricant will help reduce friction and wear, prolonging the machine’s lifespan.

Inspecting the machine for any signs of wear or damage is also essential in maintaining its functionality. Check for loose or damaged parts, such as belts, gears, and bearings, and replace them as needed. Keeping an eye on the tension of the wire being wound onto the spool is also important, as improper tension can lead to uneven winding and potential breakage.

In addition to regular maintenance, troubleshooting any issues that may arise with the horizontal wire spooler machine is crucial to prevent downtime and production delays. One common issue that may occur is uneven winding of the wire onto the spool. This can be caused by improper tension, misalignment of the spool, or worn-out components. Adjusting the tension, realigning the spool, or replacing worn parts can help resolve this issue.

Another common problem with horizontal wire spooler machines is jamming or sticking of the wire during winding. This can be caused by a variety of factors, such as debris buildup, improper alignment, or worn-out components. Clearing any obstructions, realigning the wire path, and replacing damaged parts can help resolve this issue and prevent further jams.

If the machine is making unusual noises or vibrations during operation, it may indicate a more serious issue that requires immediate attention. Inspect the machine for loose or damaged parts, and consult the manufacturer’s manual for troubleshooting tips. If the issue persists, it may be necessary to contact a professional technician for further assistance.

In conclusion, proper maintenance and troubleshooting of horizontal wire spooler machines are essential to ensure their optimal performance and longevity. Regular cleaning, lubrication, and inspection of the machine’s components will help prevent issues and prolong its lifespan. Addressing any problems that may arise promptly and effectively will help minimize downtime and production delays. By following these maintenance and troubleshooting tips, you can keep your horizontal wire spooler machine running smoothly and efficiently for years to come.

Benefits of Using Horizontal Wire Spooler Machine in Industrial Applications

In industrial applications where Wire Spooling Machine is a common task, the use of a horizontal wire spooler machine can offer numerous benefits. This specialized piece of equipment is designed to efficiently wind wire onto spools in a horizontal orientation, making it ideal for a wide range of industries such as telecommunications, construction, and manufacturing. In this article, we will explore the advantages of using a horizontal wire spooler machine in industrial settings.

One of the primary benefits of using a HORIZONTAL WIRE SPOOLING MACHINE is its ability to increase productivity. By automating the wire spooling process, this machine can significantly reduce the time and labor required to wind wire onto spools manually. This can lead to faster production times and increased output, ultimately improving the overall efficiency of the operation.

Additionally, a horizontal wire spooler machine can help improve the quality and consistency of the spooled wire. By using precise tension control and alignment mechanisms, this machine can ensure that the wire is wound evenly and securely onto the spool. This can help prevent tangling, kinking, and other issues that can arise when spooling wire manually, resulting in a higher quality end product.

Another advantage of using a horizontal wire spooler machine is its versatility. These machines are available in a range of sizes and configurations to accommodate different types and sizes of wire. Whether you are spooling thin gauge wire for telecommunications applications or thick gauge wire for construction projects, there is a horizontal wire spooler machine that can meet your needs.

Furthermore, horizontal wire spooler machines are designed with safety in mind. These machines are equipped with safety features such as emergency stop buttons, guards, and sensors to help prevent accidents and injuries in the workplace. By using a horizontal wire spooler machine, you can create a safer working environment for your employees and reduce the risk of costly downtime due to accidents.

In addition to these benefits, using a horizontal wire spooler machine can also help reduce waste and save money. By ensuring that wire is spooled efficiently and accurately, this machine can help minimize scrap and rework, ultimately reducing material costs and improving the bottom line. Additionally, the increased productivity and efficiency provided by a horizontal wire spooler machine can help lower operating costs and improve overall profitability.

Overall, the use of a horizontal wire spooler machine in industrial applications can offer a wide range of benefits, including increased productivity, improved quality, versatility, safety, and cost savings. Whether you are spooling wire for telecommunications, construction, or manufacturing, investing in a horizontal wire spooler machine can help streamline your operations and drive success in your business.