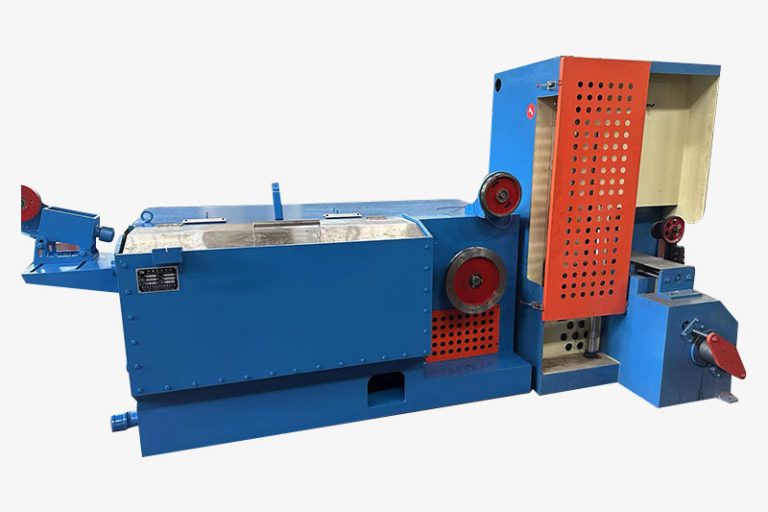

Product Description:

- For cleaning sanding or removing surface defects by means of 2 sanding belts as well as optionally by means of a pressing device

30% more sanding surface than commercially available allows for particularly long sanding belt life and best productivity Suitable for any wire quality

Flyer and both sand belt speeds independent and seperate adjustable

Noise-proof design on high level Inlet and outfeed sanding belt driven by separate motor (coarse and fine sanding possible) Automatic belt tear control - MaterialLow carbon steel wire rodWire rod diameter rangeΦ5.5mm—Φ6.5mmMax speed for wire speed150m/minMain shaft0—600rpm AdjustableRollerDouble rollers with strut systemPowerFlayer motor 15kw; Belt driving motor 4kwSuctionSuction connection is available, but the price is covered in the offerMachine directionInlet direction from left to rightElectrical cabinetRittal; IP54Electrical systemWork separated or work with wire drawing machineSand paper tension adjustmentBelt balance automatically device is availableMotorHengdaSpeed adjustableBelt speed can be adjustable (3 range of speed)PLCDeltaTouch screenDeltaSand paper broken inspectionDeltaLow voltage electrical partsSchneiderInverterInnovanceAir, and supply powerSupply by ender userThe center height915mmNote:380V/50HZ

Product Feature:

- High-Speed Double Head design for perfect abrasive sanding at speeds up to 3.0 m/s.

- SDJ-1310 descalers are designed for low, medium, high carbon and stainless-steel rod.

- Rod inlet diameter from 4.75 up to 12mm Modular construction for ease of instruction.

- Multiple units may be installed in-line for progressive rod surface finish applications.

- Quick sanding belt change by single action lever.

- Operator friendly control panel and convenient access doors for superior productivity and ease of use.

- Supplied with dust collector.