Table of Contents

Benefits of Using a wet wire drawing machine for Aluminium Wire

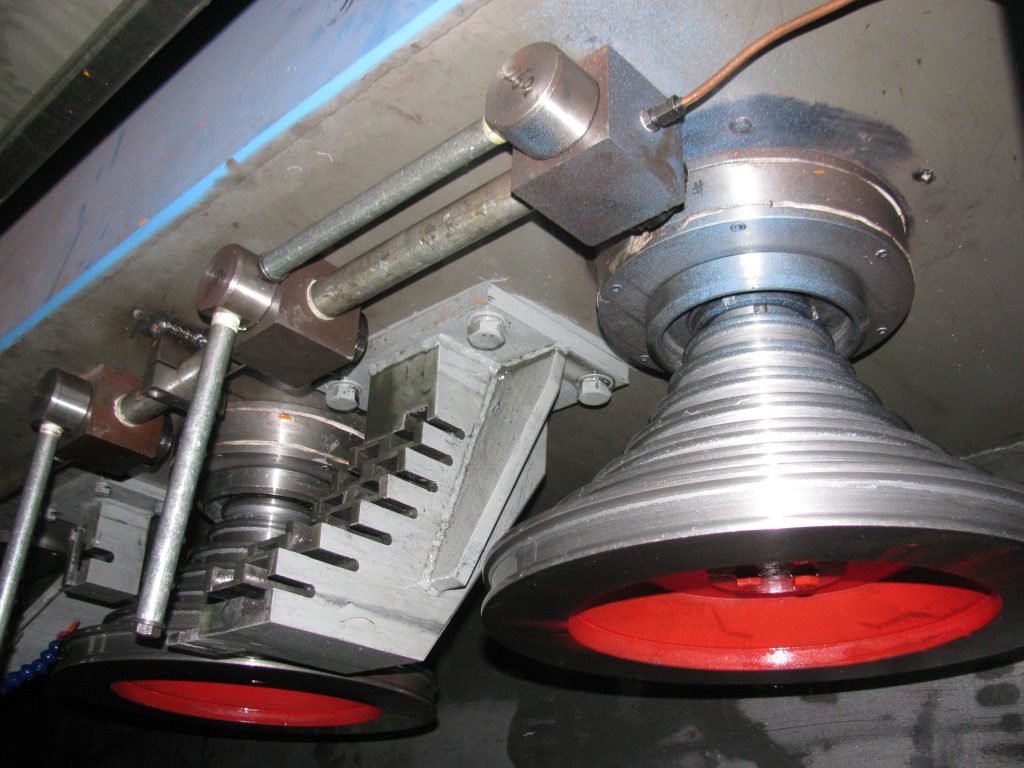

A wet wire drawing machine is a crucial piece of equipment in the manufacturing process of aluminium wire. This machine is designed to reduce the diameter of the wire by pulling it through a series of dies, resulting in a smoother and more uniform surface finish. There are several benefits to using a wet wire drawing machine for aluminium wire, which we will explore in this article.

One of the main advantages of using a wet wire drawing machine is the improved quality of the finished product. The wet drawing process involves using a lubricant or coolant to reduce friction between the wire and the dies, resulting in a smoother surface finish and more consistent diameter throughout the length of the wire. This leads to a higher quality product that is more suitable for use in a wide range of applications.

In addition to improving the quality of the wire, a wet wire drawing machine also helps to increase the productivity of the manufacturing process. The use of a lubricant or coolant reduces the amount of heat generated during the drawing process, which in turn reduces the risk of the wire breaking or becoming damaged. This allows for faster drawing speeds and higher production rates, ultimately leading to cost savings for the manufacturer.

Another benefit of using a wet wire drawing machine is the extended lifespan of the dies. The lubricant or coolant used in the drawing process helps to reduce wear and tear on the dies, resulting in a longer lifespan and lower maintenance costs. This means that manufacturers can produce high-quality aluminium wire for longer periods of time without having to replace the dies as frequently.

Furthermore, a wet wire drawing machine offers greater flexibility in terms of the types of wire that can be produced. The use of a lubricant or coolant allows for the drawing of a wider range of wire sizes and materials, making it easier for manufacturers to meet the specific requirements of their customers. This flexibility can help to attract new customers and expand the range of products that a manufacturer is able to offer.

In conclusion, the benefits of using a wet wire drawing machine for aluminium wire are clear. From improved quality and productivity to extended die lifespan and greater flexibility, this machine offers a range of advantages that can help manufacturers to produce high-quality wire more efficiently and cost-effectively. If you are in the market for a wet wire drawing machine for aluminium wire, be sure to consider these benefits and how they can help to improve your manufacturing process.

How to Choose the Right Wet Wire Drawing Machine for Your Aluminium Wire Production Line

When it comes to producing high-quality aluminium wire, having the right equipment is essential. One key piece of machinery that is crucial for the production process is a wet wire drawing machine. This machine is used to reduce the diameter of the wire by pulling it through a series of dies, resulting in a smoother surface finish and improved mechanical properties.

When looking to purchase a wet wire drawing machine for your aluminium wire production line, there are several factors to consider to ensure you choose the right one for your specific needs. One of the first things to consider is the size and capacity of the machine. You will need to determine the maximum diameter of the wire you will be drawing, as well as the desired final diameter. This will help you choose a machine that can handle the size and volume of wire you will be working with.

Another important factor to consider is the speed and efficiency of the machine. A faster machine will be able to produce more wire in less time, increasing your overall productivity. Look for a machine that offers variable speed control, so you can adjust the speed to meet your production requirements.

In addition to size and speed, it is also important to consider the quality and durability of the machine. Look for a machine that is made from high-quality materials and has a solid construction. This will ensure that the machine can withstand the rigors of daily use and provide reliable performance for years to come.

When shopping for a wet wire drawing machine, it is also important to consider the level of automation and control features. Some machines offer advanced automation features, such as digital controls and monitoring systems, which can help improve efficiency and reduce the risk of errors. Look for a machine that offers the level of automation that best suits your production needs.

Finally, consider the reputation and reliability of the manufacturer. Look for a company that has a proven track record of producing high-quality wire drawing machines and providing excellent customer service. Reading reviews and testimonials from other customers can help you gauge the reputation of a manufacturer and make an informed decision.

In conclusion, choosing the right wet wire drawing machine for your aluminium wire production line is essential for achieving high-quality results and maximizing productivity. Consider factors such as size, speed, quality, automation, and manufacturer reputation when making your decision. By taking the time to research and evaluate your options, you can find a machine that meets your specific needs and helps you achieve success in your wire production operations.