Table of Contents

Advantages of Using Wet Type Wire Drawing Machine

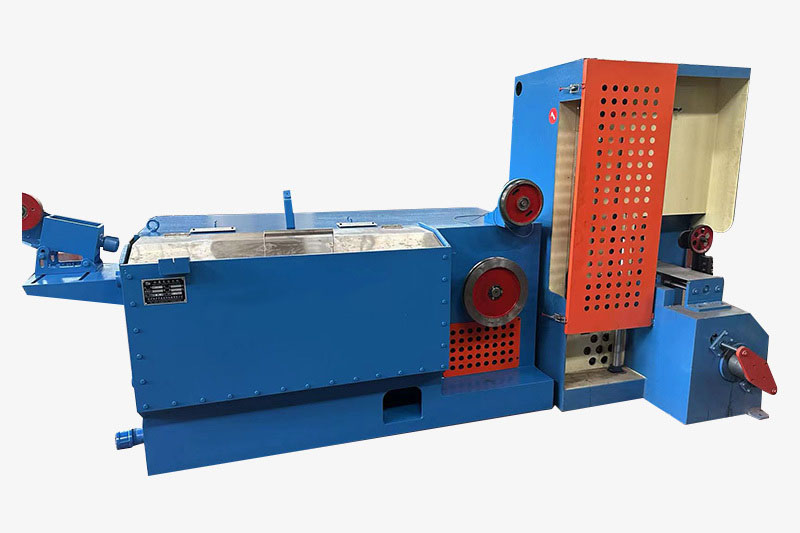

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One of the key components in the wire drawing process is the wire drawing machine, which comes in different types depending on the specific requirements of the application. One popular type of wire drawing machine is the wet wire drawing machine, which offers several advantages over other types of wire drawing machines.

One of the main advantages of using a wet type wire drawing machine is its ability to reduce friction during the wire drawing process. In a wet type wire drawing machine, the wire is drawn through a lubricant or coolant, which helps to reduce the heat generated during the process. This not only helps to protect the wire from damage but also ensures a smoother and more efficient drawing process. The reduced friction also helps to extend the life of the dies used in the machine, resulting in lower maintenance costs and increased productivity.

Another advantage of using a wet type wire drawing machine is its ability to produce wires with a higher surface finish. The lubricant or coolant used in the machine helps to remove any surface imperfections on the wire, resulting in a smoother and more polished finish. This is particularly important for applications where the appearance of the wire is important, such as in the production of jewelry or fine wire mesh. The higher surface finish also helps to improve the overall quality of the wire, making it more suitable for use in precision applications.

In addition to reducing friction and improving surface finish, a wet type wire drawing machine also offers better control over the wire drawing process. The lubricant or coolant used in the machine can be adjusted to suit the specific requirements of the application, allowing for greater precision and consistency in the wire drawing process. This level of control is particularly important for applications where tight tolerances are required, such as in the production of medical devices or aerospace components. The ability to adjust the lubricant or coolant also allows for greater flexibility in the types of wires that can be produced, making the machine suitable for a wide range of applications.

Furthermore, a wet type wire drawing machine is also more environmentally friendly compared to other types of wire drawing machines. The use of a lubricant or coolant helps to reduce the amount of heat generated during the wire drawing process, which in turn reduces energy consumption. Additionally, the lubricant or coolant can be recycled and reused, further reducing waste and environmental impact. This makes the wet type wire drawing machine a more sustainable option for manufacturers looking to reduce their carbon footprint and operate more efficiently.

In conclusion, the wet type wire drawing machine offers several advantages over other types of wire drawing machines. From reducing friction and improving surface finish to providing better control over the wire drawing process and being more environmentally friendly, the wet type wire drawing machine is a versatile and efficient option for manufacturers looking to produce high-quality wires for a wide range of applications.

Maintenance Tips for Wet Type Wire Drawing Machine

Wire drawing machines are essential equipment in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. One common type of wire drawing machine is the wet type wire drawing machine, which uses a coolant to reduce friction and heat during the drawing process. Proper maintenance of a wet type wire drawing machine is crucial to ensure its optimal performance and longevity. In this article, we will discuss some maintenance tips for wet type wire drawing machines.

Regular cleaning and inspection of the machine are essential to prevent any build-up of dirt, debris, or coolant residue that can affect its performance. Start by turning off the machine and disconnecting it from the power source. Use a clean cloth or brush to remove any dirt or debris from the machine’s exterior and interior components. Pay special attention to the dies, rollers, and coolant system, as these are the areas most prone to build-up.

After cleaning, inspect the machine for any signs of wear or damage. Check the dies for any cracks or chips, as these can affect the quality of the drawn wire. Inspect the rollers for any signs of wear or misalignment, as this can cause uneven drawing and wire breakage. Check the coolant system for any leaks or blockages, as proper coolant circulation is essential for reducing friction and heat during the drawing process.

In addition to regular cleaning and inspection, it is important to lubricate the machine’s moving parts to ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer and apply it to the dies, rollers, and other moving components. Be sure to follow the manufacturer’s guidelines for the type and frequency of lubrication to prevent over-lubrication, which can attract dirt and debris.

Another important maintenance tip for wet type wire drawing machines is to monitor the coolant levels and quality regularly. Check the coolant reservoir and top it up if necessary to ensure proper coolant circulation. Inspect the coolant for any signs of contamination, such as dirt, debris, or metal particles, and replace it if needed. Proper coolant maintenance is crucial for reducing friction and heat during the drawing process and extending the life of the machine’s components.

It is also important to check the tension and alignment of the wire during the drawing process. Improper tension or alignment can cause wire breakage or uneven drawing, affecting the quality of the drawn wire. Adjust the tension and alignment as needed to ensure smooth and consistent drawing.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the wet type wire drawing machine. Regular maintenance tasks, such as cleaning, inspection, lubrication, and coolant replacement, should be performed at specified intervals to prevent premature wear and damage to the machine.

In conclusion, proper maintenance of a wet type wire drawing machine is essential to ensure its optimal performance and longevity. Regular cleaning, inspection, lubrication, coolant maintenance, and monitoring of tension and alignment are key maintenance tips for keeping the machine in top condition. By following these maintenance tips and the manufacturer’s guidelines, you can extend the life of your wet type wire drawing machine and ensure high-quality drawn wire for your manufacturing processes.