Table of Contents

Merits of Using Rotating Die Holders for Wire Drawing Machines

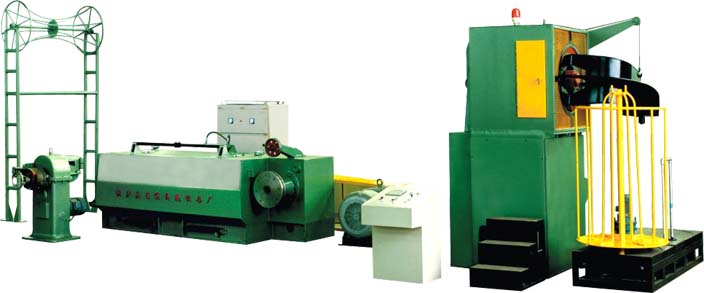

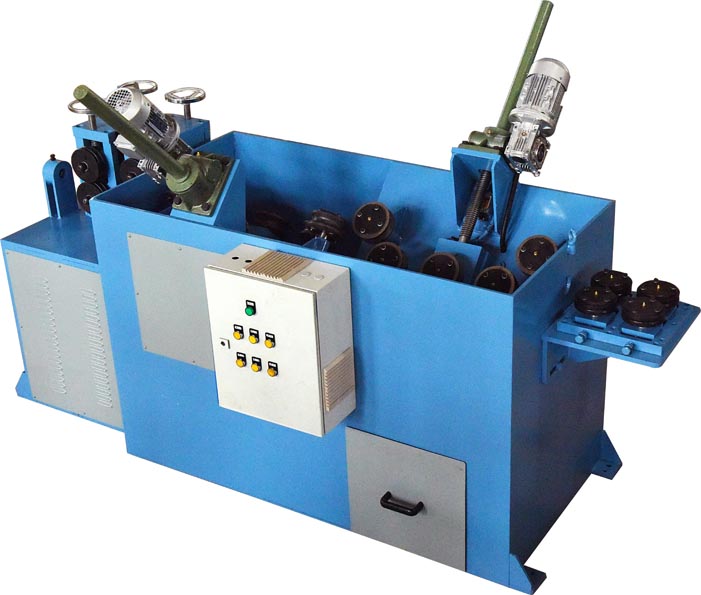

Wire drawing machines are essential tools in the manufacturing industry for producing wires of various sizes and shapes. These machines are used to pull a metal wire through a series of dies to reduce its diameter and improve its quality. One crucial component of a wire drawing machine is the die holder, which holds the die securely in place during the drawing process. Traditional die holders are fixed in position, but rotating die holders offer several benefits that can improve the efficiency and performance of wire drawing machines.

One of the primary advantages of using rotating die holders is the ability to adjust the angle of the die during the drawing process. This feature allows operators to optimize the wire drawing process by controlling the entry angle of the wire into the die. By adjusting the angle of the die, operators can reduce friction and wear on the die, resulting in a smoother drawing process and higher quality wire output.

In addition to adjusting the entry angle of the wire, rotating die holders also allow operators to change the orientation of the die itself. This flexibility is particularly useful when drawing wires with complex shapes or profiles. By rotating the die, operators can ensure that the wire is drawn evenly and consistently, resulting in a more uniform product.

Another merit of using rotating die holders is the ability to easily replace worn or damaged dies. Traditional fixed die holders require the entire holder to be removed and disassembled in order to replace the die. This process can be time-consuming and labor-intensive, leading to downtime and decreased productivity. Rotating die holders, on the other hand, allow operators to quickly and easily swap out dies without having to disassemble the entire holder. This not only saves time but also reduces the risk of damaging other components of the machine.

Furthermore, rotating die holders can help extend the life of the dies themselves. By allowing the dies to rotate during the drawing process, wear and tear are distributed more evenly across the die surface. This can help prevent premature wear and prolong the life of the die, ultimately reducing maintenance costs and downtime.

In addition to these practical benefits, rotating die holders can also improve the overall efficiency of wire drawing machines. By optimizing the drawing process and reducing friction, rotating die holders can help increase the speed and throughput of the machine. This can lead to higher production volumes and lower operating costs, making rotating die holders a cost-effective investment for manufacturers.

Overall, rotating die holders offer a range of benefits that can improve the performance, efficiency, and longevity of wire drawing machines. By allowing operators to adjust the angle and orientation of the die, easily replace worn or damaged dies, and extend the life of the dies themselves, rotating die holders can help manufacturers produce high-quality wires more efficiently and cost-effectively. Whether you are looking to improve the quality of your wire products or increase the productivity of your wire drawing operations, rotating die holders are a valuable tool to consider.

How to Properly Maintain and Care for Rotating Die Holders in Wire Drawing Machines

Rotating die holders are an essential component of wire drawing machines, responsible for holding the dies in place and ensuring a smooth and efficient wire drawing process. Proper maintenance and care of these rotating die holders are crucial to the overall performance and longevity of the wire drawing machine. In this article, we will discuss some key tips on how to properly maintain and care for rotating die holders in wire drawing machines.

First and foremost, it is important to regularly inspect the rotating die holders for any signs of wear and tear. Check for any cracks, dents, or other damage that may affect the performance of the die holder. If any damage is found, it is important to replace the rotating die holder immediately to prevent any further issues during the wire drawing process.

In addition to regular inspections, it is also important to clean the rotating die holders on a regular basis. Over time, dirt, debris, and other contaminants can build up on the die holders, affecting their performance. Use a soft brush or cloth to gently clean the rotating die holders, being careful not to damage the surface of the holder. Avoid using harsh chemicals or abrasive materials, as these can cause damage to the die holder.

Another important aspect of maintaining rotating die holders is proper lubrication. Lubrication helps to reduce friction between the die holder and the dies, allowing for a smoother wire drawing process. Be sure to use the appropriate lubricant for the rotating die holders, as using the wrong type of lubricant can cause damage to the holder. Apply a small amount of lubricant to the rotating die holders regularly to ensure smooth operation.

In addition to regular cleaning and lubrication, it is also important to properly adjust the rotating die holders as needed. Over time, the die holders may become misaligned or loose, affecting the wire drawing process. Check the alignment of the rotating die holders regularly and make any necessary adjustments to ensure proper alignment. Tighten any loose screws or bolts to prevent the die holders from shifting during operation.

Proper storage of rotating die holders is also important for maintaining their performance. When not in use, store the rotating die holders in a clean, dry area to prevent any damage or contamination. Avoid storing the die holders near any sources of heat or moisture, as this can cause damage to the holder. Proper storage will help to prolong the life of the rotating die holders and ensure optimal performance during the wire drawing process.

In conclusion, proper maintenance and care of rotating die holders are essential for the overall performance and longevity of wire drawing machines. Regular inspections, cleaning, lubrication, adjustment, and storage are all key aspects of maintaining rotating die holders. By following these tips, you can ensure that your wire drawing machine operates smoothly and efficiently, producing high-quality wire products. Remember to always consult the manufacturer’s guidelines for specific maintenance instructions for your rotating die holders.