Table of Contents

Understanding of Nail Cutter in Nail Making Machine Accessories

Nail cutters are an essential accessory in nail making machines, providing numerous benefits that contribute to the efficiency and quality of the nail production process. These cutters play a crucial role in shaping and cutting nails to the desired length, ensuring uniformity and precision in the final product. By incorporating nail cutters into the nail making machine accessories, manufacturers can streamline their operations and enhance the overall performance of their production line.

One of the key benefits of using nail cutters in nail making machines is the ability to customize the length of the nails being produced. With adjustable settings, operators can easily set the desired length of the nails, allowing for flexibility in production and the ability to meet specific customer requirements. This level of customization ensures that each nail is cut to the exact specifications, resulting in a consistent and high-quality end product.

In addition to customization, nail cutters also contribute to the efficiency of the nail making process. By automating the cutting process, operators can significantly reduce the time and labor required to produce nails, increasing productivity and output. This not only saves time and resources but also allows manufacturers to meet production deadlines and fulfill orders in a timely manner. The use of nail cutters in nail making machines helps streamline operations and optimize the production process for maximum efficiency.

Furthermore, nail cutters play a crucial role in ensuring the safety of operators and maintaining a safe working environment. By automating the cutting process, operators can avoid the risks associated with manual cutting methods, such as injuries from sharp edges or repetitive strain injuries. Nail cutters provide a safe and reliable way to cut nails with precision and accuracy, minimizing the potential for accidents and ensuring the well-being of workers on the production line.

Another benefit of using nail cutters in nail making machines is the improved quality of the end product. By cutting nails with precision and uniformity, nail cutters help maintain consistent quality standards and produce nails that meet the required specifications. This level of precision ensures that each nail is cut to the exact length, resulting in a uniform and professional finish. The use of nail cutters in nail making machines helps manufacturers achieve a high level of quality control and produce nails that meet the highest standards of excellence.

Overall, nail cutters are an essential accessory in nail making machines that offer a wide range of benefits to manufacturers. From customization and efficiency to safety and quality, nail cutters play a crucial role in optimizing the production process and enhancing the overall performance of the nail making machine. By incorporating nail cutters into their accessories, manufacturers can improve productivity, ensure safety, and produce high-quality nails that meet the demands of their customers. The use of nail cutters in nail making machines is a valuable investment that can help manufacturers achieve success in the competitive nail industry.

How to Properly Maintain and Clean Nail Cutter for Longevity

Nail cutters are an essential component of nail making machine accessories. They play a crucial role in shaping and cutting nails to the desired length and shape. Proper maintenance and cleaning of nail cutters are essential to ensure their longevity and optimal performance. In this article, we will discuss the importance of maintaining and cleaning nail cutters, as well as provide some tips on how to do so effectively.

One of the main reasons why it is important to maintain and clean nail cutters is to prevent them from becoming dull or damaged. Dull or damaged nail cutters can result in uneven or jagged nails, which can be unsightly and uncomfortable. Regular maintenance and cleaning can help to keep nail cutters sharp and in good working condition.

To properly maintain nail cutters, it is important to regularly inspect them for any signs of wear or damage. This includes checking for any nicks or chips in the cutting edge, as well as ensuring that the blades are properly aligned. If any damage is found, it is important to address it promptly to prevent further deterioration.

In addition to regular inspections, it is also important to clean nail cutters regularly to remove any buildup of dirt, oil, or debris. This can be done by using a soft brush or cloth to gently scrub the blades and remove any residue. It is important to avoid using harsh chemicals or abrasive materials, as these can damage the blades and reduce their effectiveness.

When cleaning nail cutters, it is also important to pay attention to the moving parts and mechanisms. These areas can become clogged with debris over time, which can affect the overall performance of the nail cutter. To clean these areas, it is important to use a small brush or cotton swab to remove any buildup and ensure that the moving parts are able to function properly.

In addition to regular maintenance and cleaning, it is also important to store nail cutters properly when not in use. This includes keeping them in a dry and clean environment, away from moisture and humidity. Storing nail cutters in a protective case or pouch can help to prevent damage and ensure that they remain in good condition for longer.

By following these tips for maintaining and cleaning nail cutters, you can help to ensure their longevity and optimal performance. Proper maintenance and cleaning can help to prevent damage and keep nail cutters sharp and effective for longer. With regular inspections, cleaning, and proper storage, you can extend the life of your nail cutters and ensure that they continue to provide you with clean and precise nail cuts for years to come.

Comparison of Different Types of Nail Cutters for Nail Making Machine Accessories

Nail cutters are an essential accessory for nail making machines, as they are responsible for cutting the nails to the desired length. There are several types of nail cutters available on the market, each with its own unique features and benefits. In this article, we will compare different types of nail cutters for nail making machine accessories to help you make an informed decision.

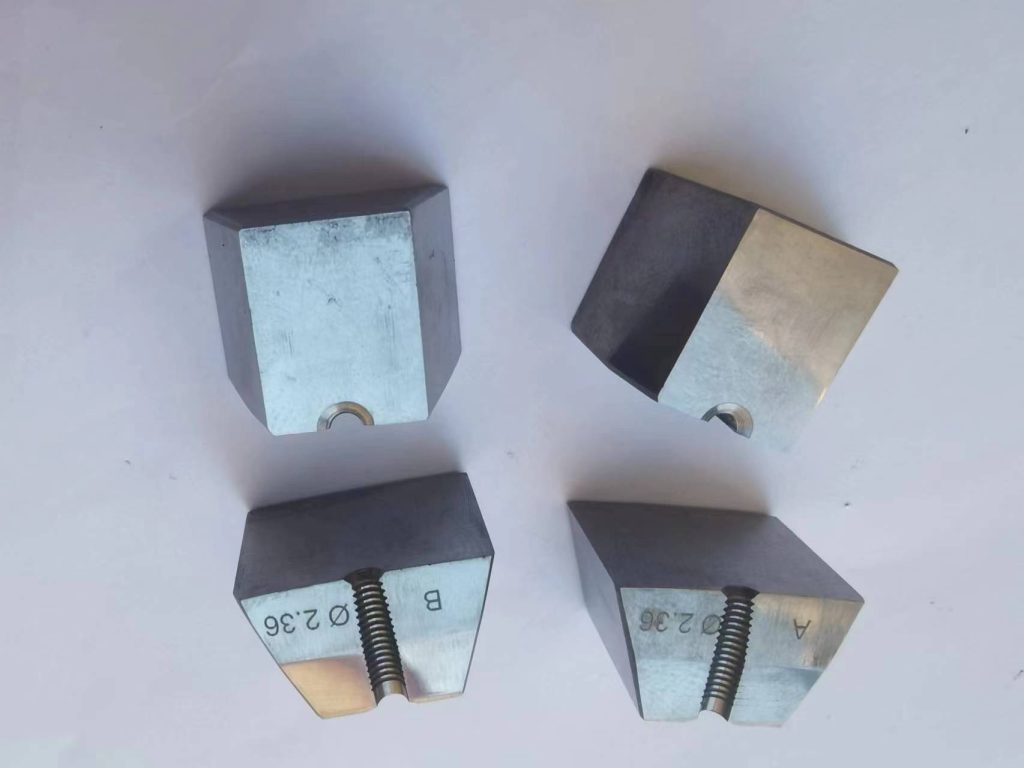

One of the most common types of nail cutters for nail making machine accessories is the guillotine cutter. This type of cutter features a sharp blade that is used to cut the nails quickly and efficiently. Guillotine cutters are known for their precision and accuracy, making them a popular choice among nail manufacturers. However, guillotine cutters can be more expensive than other types of nail cutters, so it is important to consider your budget when choosing this option.

Another popular type of nail cutter for nail making machine accessories is the rotary cutter. This type of cutter features a rotating blade that is used to cut the nails in a circular motion. Rotary cutters are known for their speed and efficiency, making them a great option for high-volume nail production. However, rotary cutters can be more difficult to operate than guillotine cutters, so it is important to have proper training and experience when using this type of cutter.

In addition to guillotine and rotary cutters, there are also specialty nail cutters available for nail making machine accessories. For example, there are cutters specifically designed for cutting wire nails, as well as cutters that can handle different nail sizes and shapes. Specialty nail cutters are a great option for manufacturers who have specific requirements for their nail production process.

When choosing a nail cutter for your nail making machine accessories, it is important to consider the size and type of nails you will be cutting. Some nail cutters are designed for cutting small nails, while others are better suited for larger nails. It is also important to consider the material of the nails you will be cutting, as some cutters are better suited for cutting certain types of metal.

In addition to considering the size and type of nails you will be cutting, it is also important to consider the quality of the nail cutter itself. Look for a cutter that is made from high-quality materials and has a sharp blade that will provide clean and precise cuts. It is also important to choose a cutter that is easy to maintain and clean, as this will help prolong the life of the cutter and ensure consistent performance.

In conclusion, there are several types of nail cutters available for nail making machine accessories, each with its own unique features and benefits. Whether you choose a guillotine cutter, rotary cutter, or specialty nail cutter, it is important to consider your specific needs and requirements when making your decision. By choosing the right nail cutter for your nail making machine accessories, you can ensure efficient and accurate nail production for your business.