Understanding of Using a Dry Type Wire Drawing Machine

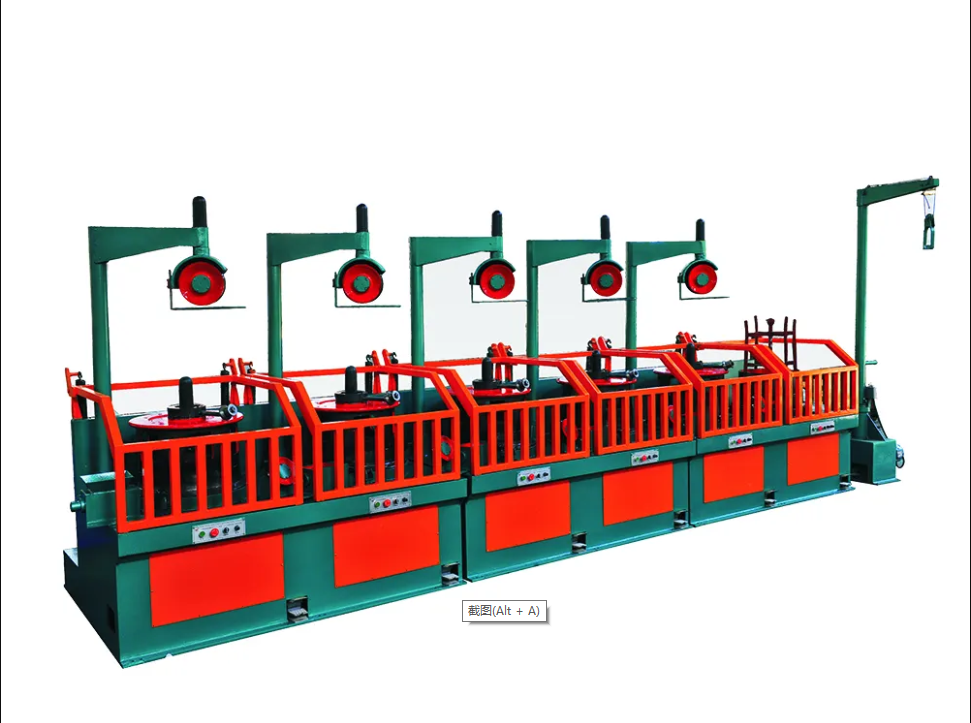

A dry type wire drawing machine is a crucial piece of equipment used in the manufacturing industry to produce high-quality wire products. This machine is designed to draw wire through a series of dies to reduce its diameter and improve its surface finish. Unlike traditional wet drawing machines that use lubricants such as oil or soap to reduce friction and heat during the drawing process, dry type wire drawing machines operate without the need for any lubricants. This makes them more environmentally friendly and cost-effective compared to their wet drawing counterparts.

One of the key benefits of using a dry type wire drawing machine is its ability to produce wire with a higher surface quality. Since there are no lubricants involved in the drawing process, the wire produced by a dry type machine is cleaner and free from any residue that may affect its performance. This results in a smoother surface finish and improved mechanical properties, making the wire suitable for a wide range of applications in industries such as automotive, construction, and electronics.

Another advantage of using a OTO Type Wire Drawing Machine is its energy efficiency. Traditional wet drawing machines require a significant amount of energy to operate due to the need for lubricants and cooling systems. In contrast, dry type machines operate at lower temperatures and do not require any additional cooling, resulting in reduced energy consumption and lower operating costs. This makes them a more sustainable option for manufacturers looking to reduce their carbon footprint and energy expenses.

Furthermore, dry type wire drawing machines are easier to maintain and operate compared to wet drawing machines. Since there are no lubricants involved, there is less risk of contamination and maintenance issues that may arise from the use of lubricants. This results in reduced downtime and lower maintenance costs, allowing manufacturers to increase their productivity and efficiency.

In addition to these benefits, dry type wire drawing machines offer greater flexibility and versatility in terms of wire production. They can be easily adjusted to accommodate different wire sizes and materials, allowing manufacturers to produce a wide range of wire products to meet the specific requirements of their customers. This flexibility makes dry type machines a valuable investment for manufacturers looking to expand their product offerings and enter new markets.

Overall, the use of a dry type wire drawing machine offers numerous benefits for manufacturers looking to improve the quality, efficiency, and sustainability of their wire production processes. From higher surface quality and energy efficiency to easier maintenance and greater flexibility, dry type machines provide a cost-effective and environmentally friendly solution for producing high-quality wire products. As the demand for wire products continues to grow in various industries, investing in a dry type wire drawing machine can help manufacturers stay competitive and meet the evolving needs of their customers.