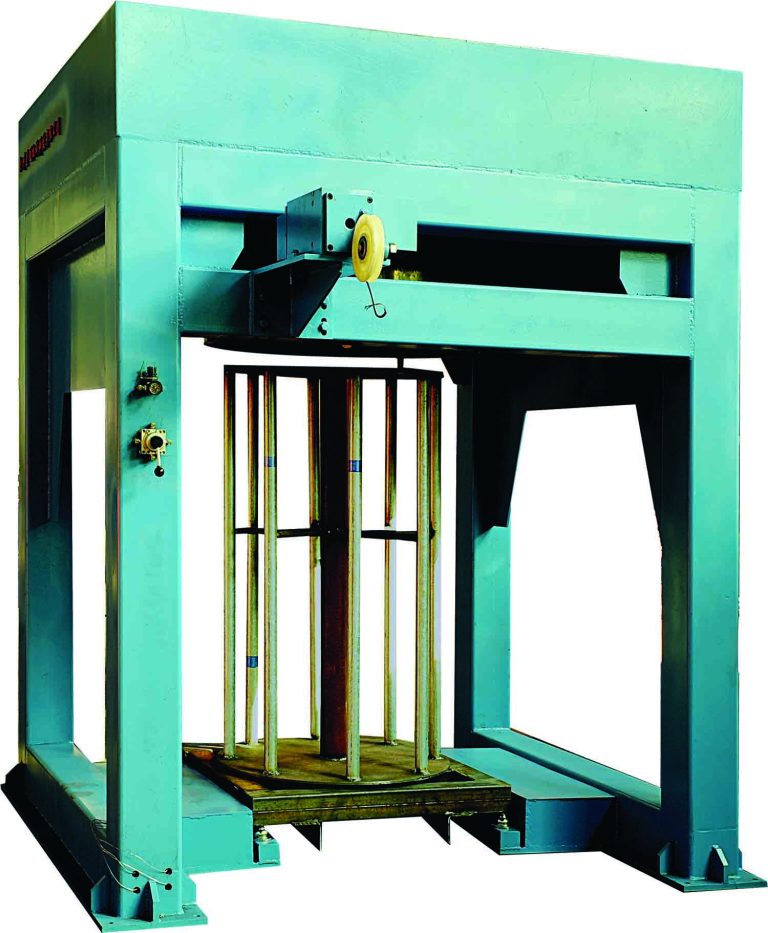

Wire Cutting Machine in a Welding Electrode Plant in China

Welding electrode plants play a crucial role in the manufacturing of welding electrodes, which are essential components in various industries. One of the key machines used in these plants is the wire cutting machine. This machine is designed to cut welding wire to the desired length, ensuring precision and efficiency in the production process.

One of the main benefits of using a wire cutting machine in a welding electrode plant is increased productivity. By automating the process of cutting welding wire, the machine can significantly reduce the time and labor required to produce welding electrodes. This allows the plant to produce a higher volume of electrodes in a shorter amount of time, ultimately increasing overall productivity and profitability.

In addition to increased productivity, a wire cutting machine also helps improve the quality of welding electrodes. By cutting the wire to the exact length required for each electrode, the machine ensures consistency and accuracy in the manufacturing process. This results in welding electrodes that meet the highest standards of quality and performance, ultimately leading to greater customer satisfaction and loyalty.

Furthermore, using a wire cutting machine in a welding electrode plant can help reduce waste and minimize material costs. By cutting the wire to the precise length needed for each electrode, the machine eliminates the need for manual cutting, which can lead to errors and excess material waste. This not only helps save money on raw materials but also contributes to a more sustainable and environmentally friendly manufacturing process.

Another advantage of using a wire cutting machine in a welding electrode plant is improved safety. Manual cutting of welding wire can be a hazardous task, as it involves handling sharp objects and working with high-speed machinery. By automating the cutting process, the machine reduces the risk of accidents and injuries, creating a safer work environment for plant employees.

Additionally, a wire cutting machine offers greater flexibility and versatility in the production of welding electrodes. The machine can be easily adjusted to cut wire to different lengths and diameters, allowing the plant to produce a wide range of electrode sizes to meet the needs of various applications and industries. This flexibility enables the plant to respond quickly to changing market demands and customer requirements, ultimately enhancing its competitiveness in the industry.

Overall, the use of a wire cutting machine in a welding electrode plant brings numerous benefits, including increased productivity, improved quality, reduced waste, enhanced safety, and greater flexibility. By investing in this essential piece of equipment, welding electrode plants can streamline their manufacturing processes, optimize their production output, and ultimately achieve greater success in the industry.