Table of Contents

How to Properly Maintain and Clean Wire Brush Descaler Machine

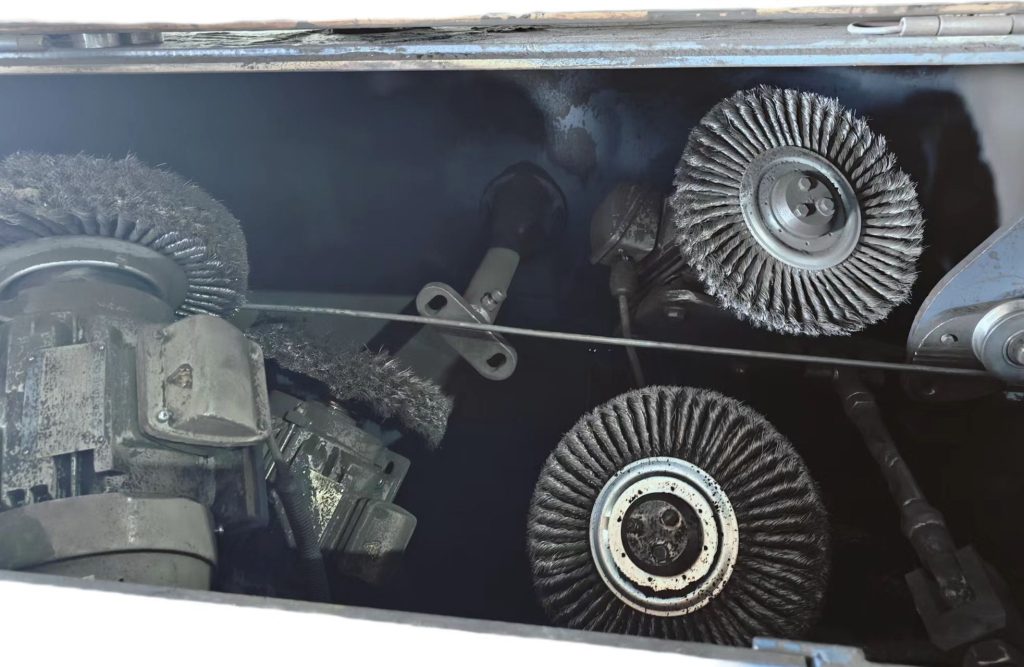

Wire brush descaler machines are essential tools in various industries for removing rust, paint, and other debris from metal surfaces. To ensure these machines continue to operate efficiently and effectively, proper maintenance and cleaning are crucial. In this article, we will discuss the steps you can take to properly maintain and clean Steel Brush Descaler for Wire Drawing Process.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. Check the wire brushes for any damage or excessive wear, as this can affect the machine’s performance. Replace any worn-out brushes immediately to prevent further damage to the machine and ensure optimal cleaning results.

In addition to inspecting the wire brushes, it is also important to check the machine’s motor and other components for any issues. Make sure all parts are properly lubricated and functioning smoothly. Any unusual noises or vibrations should be addressed promptly to prevent more serious problems from occurring.

When it comes to cleaning the wire brush descaler machine, regular maintenance is key. After each use, remove any debris or buildup from the machine to prevent it from clogging or affecting its performance. Use a brush or compressed air to clean hard-to-reach areas and ensure all parts are free from dirt and grime.

For a more thorough cleaning, you can disassemble the machine and clean each component individually. Use a mild detergent and water to clean the wire brushes and other parts, making sure to rinse them thoroughly and allow them to dry completely before reassembling the machine.

It is also important to regularly check and replace the machine’s filters to ensure proper airflow and prevent overheating. Clogged filters can reduce the machine’s efficiency and lead to more frequent breakdowns. Replace the filters according to the manufacturer’s recommendations to keep the machine running smoothly.

In addition to regular maintenance and cleaning, it is important to follow proper safety precautions when using a wire brush descaler machine. Always wear appropriate protective gear, such as gloves and safety goggles, to prevent injuries from flying debris or contact with the wire brushes. Make sure the machine is properly grounded and follow all safety guidelines provided by the manufacturer.

Proper storage of the Mechanical brush descaler machine is also important to prevent damage and ensure its longevity. Store the machine in a clean, dry area away from moisture and extreme temperatures. Cover the machine when not in use to protect it from dust and debris.

By following these maintenance and cleaning tips, you can ensure your wire brush descaler machine continues to operate efficiently and effectively. Regular inspections, cleaning, and proper storage will help prevent breakdowns and extend the machine’s lifespan. Remember to always follow safety guidelines and manufacturer recommendations to keep your machine in top condition.

Benefits of Using Wire Brush Descaler Machines in Industrial Settings

Wire brush descaler machines are essential tools in industrial settings for removing rust, scale, and other debris from metal surfaces. These machines offer a wide range of benefits that make them indispensable for maintaining equipment and ensuring optimal performance. In this article, we will explore the advantages of using wire brush descaler machines in industrial settings.

One of the primary benefits of wire brush descaler machines is their efficiency in removing rust and scale from metal surfaces. These machines use abrasive wire brushes to scrub away corrosion and debris, leaving the metal surface clean and smooth. This process is much faster and more effective than manual methods, saving time and labor costs for industrial operations.

In addition to their efficiency, wire brush descaler machines are also highly versatile. They can be used on a variety of metal surfaces, including steel, aluminum, and copper. This versatility makes them ideal for a wide range of industrial applications, from cleaning machinery and equipment to preparing surfaces for painting or coating.

Another key benefit of wire brush descaler machines is their ability to improve the performance and longevity of equipment. By removing rust and scale from metal surfaces, these machines help prevent corrosion and deterioration, extending the lifespan of industrial equipment and reducing the need for costly repairs or replacements.

Furthermore, wire brush descaler machines are easy to use and require minimal maintenance. They are designed to be user-friendly, with simple controls and adjustable settings to accommodate different types of metal surfaces. This ease of use makes them accessible to a wide range of operators, from experienced technicians to entry-level employees.

Additionally, wire brush descaler machines are cost-effective solutions for industrial operations. By reducing the need for manual labor and increasing efficiency in cleaning and maintenance tasks, these machines help businesses save money in the long run. They also help prevent costly downtime by keeping equipment in optimal condition and minimizing the risk of breakdowns or malfunctions.

Moreover, wire brush descaler machines are environmentally friendly alternatives to chemical cleaning agents. Unlike harsh chemicals that can be harmful to the environment and pose health risks to workers, these machines use mechanical abrasion to clean metal surfaces, eliminating the need for toxic substances.

In conclusion, wire brush descaler machines offer a wide range of benefits for industrial settings. From their efficiency and versatility to their ability to improve equipment performance and longevity, these machines are essential tools for maintaining metal surfaces in optimal condition. With their cost-effective and environmentally friendly features, wire brush descaler machines are valuable assets for any industrial operation looking to streamline cleaning and maintenance processes.