Table of Contents

Benefits of Using a Wire Brush Descaler Machine for Industrial Cleaning

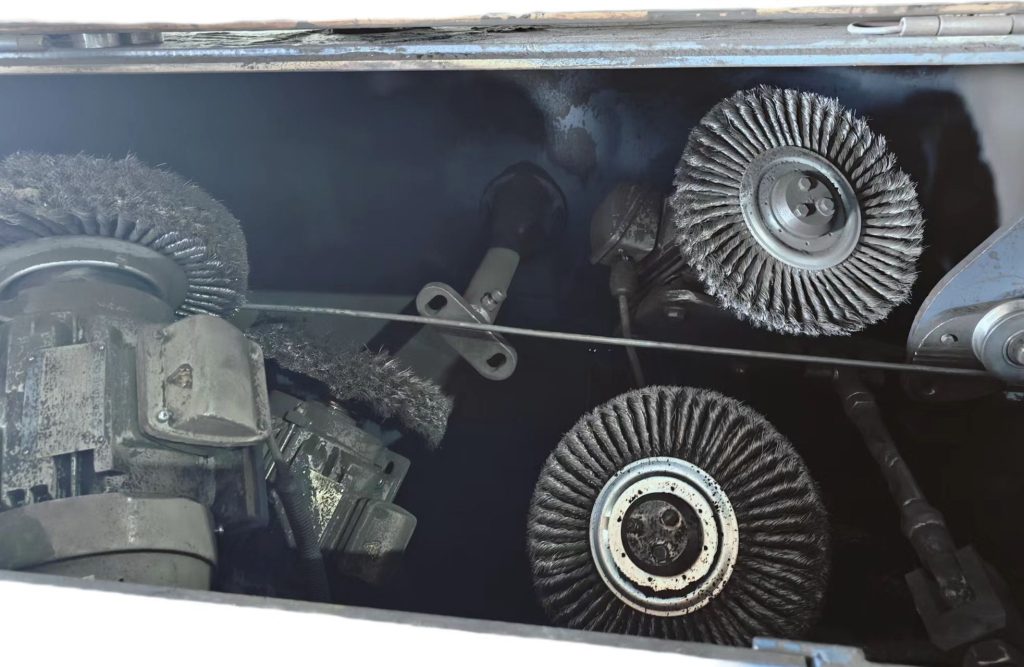

Industrial cleaning is a crucial aspect of maintaining a safe and efficient work environment. One tool that has proven to be highly effective in this regard is the wire brush descaler machine. This machine is specifically designed to remove rust, paint, and other debris from metal surfaces, making it an essential piece of equipment for industries such as manufacturing, construction, and automotive.

One of the key benefits of using a wire Steel Brush Descaler for Wire Drawing Process machine is its efficiency. Traditional methods of cleaning metal surfaces, such as sandblasting or chemical cleaning, can be time-consuming and labor-intensive. In contrast, a wire brush descaler machine can quickly and effectively remove debris from metal surfaces, saving both time and labor costs.

Another advantage of using a wire brush descaler machine is its versatility. These machines come in a variety of sizes and configurations, making them suitable for a wide range of applications. Whether you need to clean large industrial equipment or small metal parts, there is a wire brush descaler machine that can meet your needs.

In addition to being efficient and versatile, wire brush descaler machines are also environmentally friendly. Unlike chemical cleaning methods, which can release harmful fumes and pollutants into the air, wire brush descaler machines use mechanical means to clean metal surfaces. This not only reduces the environmental impact of the cleaning process but also helps to protect the health and safety of workers.

Furthermore, using a wire brush descaler machine can help to extend the lifespan of metal equipment. Rust and corrosion can weaken metal surfaces over time, leading to costly repairs or replacements. By regularly cleaning metal surfaces with a wire brush descaler machine, you can prevent rust and corrosion from taking hold, prolonging the life of your equipment and saving money in the long run.

One of the key features of a wire brush descaler machine is its ease of use. These machines are designed to be user-friendly, with simple controls and easy maintenance requirements. This makes them ideal for use in a variety of industrial settings, where time and resources are often limited.

In conclusion, the wire brush descaler machine is a valuable tool for industrial cleaning. Its efficiency, versatility, environmental friendliness, and ease of use make it an essential piece of equipment for industries that rely on metal surfaces. By investing in a wire brush descaler machine, you can save time and money, protect the environment, and extend the lifespan of your equipment.

How to Properly Maintain and Care for Your Wire Brush Descaler Machine

Wire brush descaler machines are essential tools in various industries for removing rust, paint, and other debris from metal surfaces. To ensure that your wire brush descaler machine continues to operate efficiently and effectively, proper maintenance and care are crucial. In this article, we will discuss some tips on how to properly maintain and care for your wire brush descaler machine.

First and foremost, it is important to regularly inspect your wire Mechanical brush descaler machine for any signs of wear and tear. Check the wire brushes for any damage or excessive wear, and replace them as needed. Inspect the motor and other components for any loose or damaged parts, and tighten or replace them as necessary. Regular inspections can help prevent costly repairs and downtime in the future.

In addition to regular inspections, it is important to clean your wire brush descaler machine after each use. Use a brush or compressed air to remove any debris or buildup from the wire brushes and other components. Wipe down the machine with a clean, dry cloth to remove any dust or dirt. Keeping your machine clean will not only prolong its lifespan but also ensure that it operates at peak performance.

Another important aspect of maintaining your wire brush descaler machine is to lubricate the moving parts regularly. Apply a small amount of lubricant to the bearings, gears, and other moving components to reduce friction and wear. Be sure to use the appropriate type of lubricant recommended by the manufacturer to prevent damage to the machine.

It is also important to store your wire brush descaler machine properly when not in use. Keep it in a clean, dry area away from moisture and extreme temperatures. Cover the machine with a tarp or protective cover to prevent dust and debris from accumulating on the machine. Proper storage will help prolong the lifespan of your machine and prevent damage from environmental factors.

Regularly calibrating your wire brush descaler machine is another important maintenance task. Over time, the machine may become misaligned or lose its calibration, which can affect its performance. Follow the manufacturer’s instructions for calibrating the machine, and make any necessary adjustments to ensure that it operates correctly.

Lastly, it is important to follow all safety guidelines and precautions when using your wire brush descaler machine. Wear appropriate personal protective equipment, such as gloves and safety goggles, to protect yourself from flying debris and other hazards. Follow the manufacturer’s instructions for operating the machine safely, and never attempt to use the machine in a way that it was not intended for.

In conclusion, proper maintenance and care are essential for ensuring that your wire brush descaler machine operates efficiently and effectively. By regularly inspecting, cleaning, lubricating, and storing your machine, you can prolong its lifespan and prevent costly repairs. Remember to calibrate the machine regularly and follow all safety guidelines when using the machine. With proper maintenance and care, your wire brush descaler machine will continue to be a valuable tool in your arsenal for years to come.