Table of Contents

Advantages of Using Vertical Drop Coiler for Take-Up High Carbon Steel Wire

High carbon steel wire is a crucial material used in various industries, including automotive, construction, and manufacturing. To ensure the quality and efficiency of the production process, it is essential to have a reliable and efficient coiling system in place. One popular option for take-up high carbon steel wire is the vertical drop coiler, which offers several advantages over traditional coiling methods.

One of the main advantages of using a Vertical Wire Drop Coiler for take-up high carbon steel wire is its space-saving design. Unlike horizontal coilers that require a large footprint, vertical drop coilers can be installed in a compact space, making them ideal for facilities with limited floor space. This space-saving design not only helps optimize the use of available space but also allows for easier integration into existing production lines.

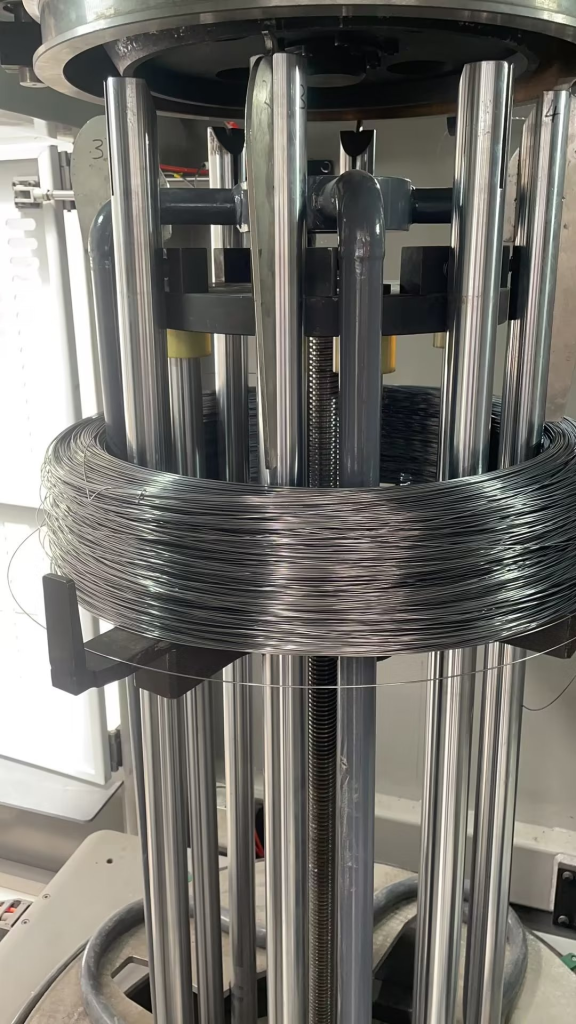

In addition to its space-saving design, a vertical drop coiler offers improved efficiency in the coiling process. The vertical orientation of the coiler allows for a more controlled and uniform winding of the high carbon steel wire, resulting in a neater and more organized coil. This improved winding quality helps reduce the risk of tangling or snags during handling and transportation, ultimately leading to a more efficient production process.

Furthermore, vertical drop coilers are designed to handle high-speed coiling operations, making them suitable for high-volume production environments. The vertical orientation of the coiler allows for faster coil changes and reduced downtime between runs, increasing overall productivity and throughput. This high-speed capability is especially beneficial for industries with demanding production schedules and tight deadlines.

Another advantage of using a vertical drop coiler for take-up high carbon steel wire is its versatility. Vertical drop coilers can be easily customized to accommodate different wire diameters, coil sizes, and winding patterns, making them suitable for a wide range of applications. Whether you are coiling thin wire for electrical applications or thick wire for industrial purposes, a vertical drop coiler can be tailored to meet your specific requirements.

Additionally, vertical drop coilers are designed with operator safety in mind. The vertical orientation of the coiler minimizes the risk of injury during coil changes and maintenance tasks, as operators can access the coiling area from a safe distance. This enhanced safety feature helps create a more secure working environment and reduces the likelihood of accidents or injuries on the production floor.

In conclusion, the vertical drop coiler offers several advantages for take-up high carbon steel wire, including space-saving design, improved efficiency, high-speed capability, versatility, and operator safety. By investing in a vertical drop coiler, manufacturers can enhance the quality and productivity of their coiling operations, ultimately leading to a more streamlined and cost-effective production process. Whether you are looking to upgrade your existing coiling system or invest in a new coiler for your facility, a vertical drop coiler is a reliable and efficient solution for handling high carbon steel wire.

Tips for Efficient Operation of Vertical Drop Coiler for Take-Up High Carbon Steel Wire

Vertical drop coilers are essential equipment in the wire manufacturing industry, particularly for high carbon steel wire. These machines are designed to efficiently coil wire onto a spool or reel as it is produced, ensuring smooth and continuous operation of the production line. To maximize the efficiency of a vertical drop coiler for take-up high carbon steel wire, there are several tips that operators should keep in mind.

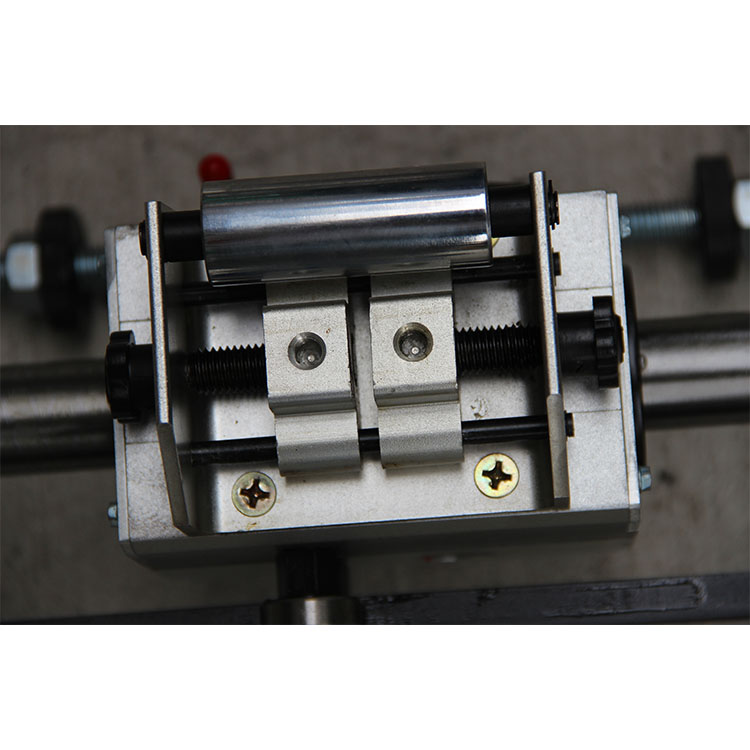

First and foremost, it is crucial to ensure that the coiler is properly set up and calibrated before starting production. This includes adjusting the tension settings, speed controls, and other parameters to match the specific requirements of the wire being produced. Proper calibration will help prevent issues such as over-coiling or under-coiling, which can lead to production delays and quality issues.

In addition to proper setup, regular maintenance of the coiler is also essential for efficient operation. This includes routine inspections of the machine for any signs of wear or damage, as well as lubrication of moving parts to prevent friction and ensure smooth operation. By keeping the coiler well-maintained, operators can minimize downtime and maximize productivity.

Another important tip for efficient operation of a vertical drop coiler is to monitor the tension of the wire as it is being coiled. Proper tension control is crucial for achieving uniform and tightly wound coils, which are essential for downstream processing and quality control. Operators should regularly check the tension settings and make adjustments as needed to ensure consistent coiling throughout the production run.

Furthermore, operators should pay close attention to the speed of the coiler in relation to the speed of the wire being produced. It is important to maintain a consistent speed ratio between the coiler and the production line to prevent issues such as over-coiling or tangling of the wire. By carefully monitoring and adjusting the speed settings, operators can ensure smooth and efficient coiling of the high carbon steel wire.

Additionally, operators should be mindful of the spool or reel size being used on the coiler. Using the correct size spool is essential for achieving optimal coil formation and preventing issues such as slippage or uneven winding. Operators should regularly check the spool size and make adjustments as needed to ensure proper coiling of the wire.

Lastly, proper training of operators is key to efficient operation of a vertical drop coiler for take-up high carbon steel wire. Operators should be well-versed in the operation of the machine, as well as safety protocols and best practices for maintenance and troubleshooting. By providing comprehensive training to operators, companies can ensure smooth and efficient operation of the coiler and minimize the risk of production issues.

In conclusion, efficient operation of a vertical drop coiler for take-up high carbon steel wire requires proper setup, regular maintenance, monitoring of tension and speed, attention to spool size, and thorough operator training. By following these tips, operators can maximize the productivity and quality of their wire manufacturing process, leading to improved efficiency and profitability.