Table of Contents

Maintenance Tips for Maximizing the Lifespan of Your wet wire drawing machine

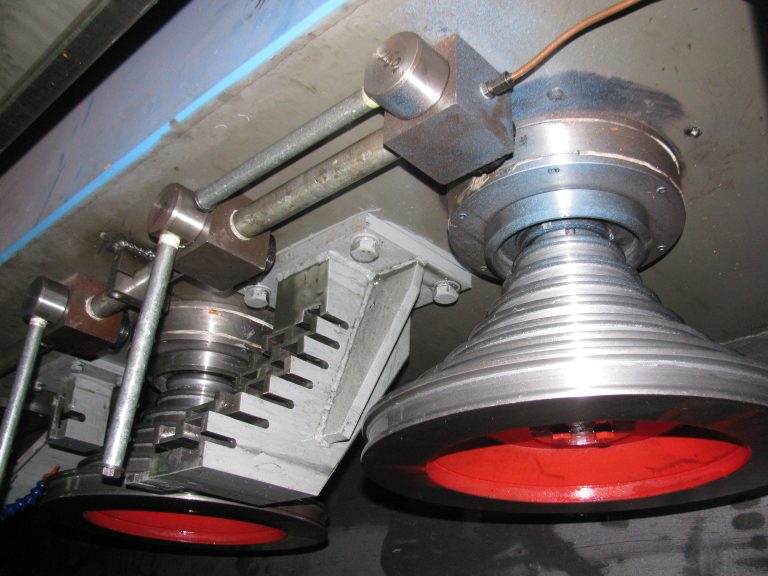

A wet wire drawing machine is a crucial piece of equipment in the manufacturing process of aluminum wire. It is used to reduce the diameter of the wire by pulling it through a series of dies, resulting in a smoother and more uniform surface finish. To ensure the machine operates efficiently and effectively, proper maintenance is essential. In this article, we will discuss some maintenance tips for maximizing the lifespan of your wet wire drawing machine.

First and foremost, regular cleaning of the machine is crucial. Over time, dirt, dust, and debris can accumulate on the machine, leading to decreased performance and potential damage. It is important to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the moving parts of the machine is essential to prevent wear and tear. Be sure to use the appropriate lubricant recommended by the manufacturer to ensure optimal performance.

Another important maintenance tip is to regularly inspect the machine for any signs of wear or damage. Check the dies, rollers, and other components for any cracks, dents, or other abnormalities that may affect the performance of the machine. If any issues are found, it is important to address them promptly to prevent further damage and ensure the longevity of the machine.

In addition to regular cleaning and inspection, it is important to follow the manufacturer’s recommended maintenance schedule. This may include replacing worn parts, adjusting settings, and performing other routine maintenance tasks to keep the machine running smoothly. By following the recommended maintenance schedule, you can prevent costly repairs and downtime, ultimately extending the lifespan of your wet wire drawing machine.

Furthermore, proper training of operators is essential to ensure the machine is used correctly and safely. Operators should be trained on how to operate the machine, perform routine maintenance tasks, and troubleshoot common issues. By providing proper training, you can prevent accidents, reduce downtime, and prolong the lifespan of your wet wire drawing machine.

Lastly, it is important to keep detailed records of maintenance and repairs performed on the machine. This can help you track the machine’s performance over time, identify any recurring issues, and make informed decisions about when to replace or upgrade the machine. By keeping accurate records, you can ensure the longevity of your wet wire drawing machine and maximize its efficiency and effectiveness.

In conclusion, proper maintenance is essential for maximizing the lifespan of your wet wire drawing machine. By following these maintenance tips, you can ensure the machine operates efficiently and effectively, prevent costly repairs, and prolong its lifespan. Remember to clean the machine regularly, inspect for wear and damage, follow the manufacturer’s recommended maintenance schedule, provide proper training to operators, and keep detailed records of maintenance and repairs. By taking these steps, you can ensure the longevity of your wet wire drawing machine and optimize its performance in the manufacturing process of aluminum wire.

How to Choose the Right Wet Wire Drawing Machine for Your Aluminum Wire Needs

When it comes to choosing the right wet wire drawing machine for your aluminum wire needs, there are several factors to consider. One of the most important considerations is the quality of the machine itself. Chinese high-quality suppliers are known for producing top-of-the-line wet wire drawing machines that are durable, efficient, and reliable.

One of the key benefits of using a Wet Wire Drawing Machine For Aluminum Wire is that it helps to improve the surface finish of the wire. This is important because a smooth surface finish can help to reduce friction and wear during the wire drawing process, resulting in a higher quality end product. Chinese high-quality suppliers understand the importance of surface finish and design their machines to produce wire with a consistent and smooth finish.

Another important factor to consider when choosing a wet wire drawing machine is the speed and efficiency of the machine. Chinese high-quality suppliers are known for producing machines that are fast and efficient, allowing you to increase your production output and reduce downtime. This can help to improve your overall productivity and profitability.

In addition to quality and efficiency, it is also important to consider the size and capacity of the wet wire drawing machine. Chinese high-quality suppliers offer a range of machines in different sizes and capacities to meet the needs of various industries. Whether you are a small-scale manufacturer or a large industrial producer, you can find a wet wire drawing machine that is suitable for your specific requirements.

When choosing a wet wire drawing machine, it is also important to consider the level of automation and control that the machine offers. Chinese high-quality suppliers design their machines with advanced automation and control systems that allow you to easily adjust settings, monitor performance, and troubleshoot any issues that may arise. This can help to streamline your production process and ensure consistent and reliable results.

In conclusion, when it comes to choosing the right wet wire drawing machine for your aluminum wire needs, Chinese high-quality suppliers are an excellent choice. Their machines are known for their quality, efficiency, and reliability, making them a top choice for manufacturers around the world. By considering factors such as surface finish, speed, capacity, and automation, you can find a wet wire drawing machine that meets your specific requirements and helps to improve your overall production process.