Advantages of Using a Wet Type Wire Drawing Machine

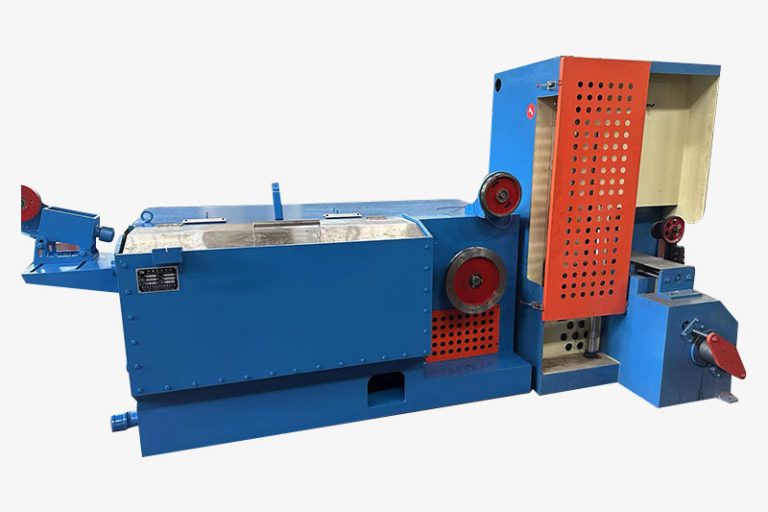

A wet type wire drawing machine is a crucial piece of equipment in the wire manufacturing industry. This machine is used to reduce the diameter of wire by pulling it through a series of dies, resulting in a smoother and more uniform wire. There are several advantages to using a wet type wire drawing machine, which we will explore in this article.

One of the main advantages of a wet type wire drawing machine is its ability to reduce friction during the drawing process. The wire is pulled through a lubricant bath before entering the dies, which helps to reduce heat and friction. This not only extends the life of the dies but also results in a smoother finish on the wire. The lubricant also helps to remove any impurities or contaminants from the wire, resulting in a cleaner and more uniform product.

Another advantage of using a wet type wire drawing machine is its ability to increase productivity. The lubricant bath helps to reduce the amount of force required to pull the wire through the dies, which means that the machine can operate at higher speeds without causing damage to the wire. This results in faster production times and higher output levels, making the machine more efficient and cost-effective.

In addition to increasing productivity, a wet type wire drawing machine also helps to improve the quality of the wire being produced. The lubricant bath helps to reduce the risk of surface defects such as scratches or marks, resulting in a higher quality finish on the wire. This is particularly important for industries that require high-quality wire for their products, such as the automotive or aerospace industries.

Furthermore, a wet type wire drawing machine is also more versatile than its dry type counterpart. The lubricant bath can be adjusted to suit different types of wire and materials, allowing for greater flexibility in the production process. This means that the machine can be used to produce a wider range of wire sizes and types, making it a more versatile and adaptable piece of equipment.

Overall, the advantages of using a wet type wire drawing machine are clear. From reducing friction and increasing productivity to improving the quality of the wire being produced, this machine offers a range of benefits for manufacturers in the wire industry. Its versatility and efficiency make it a valuable asset for any production facility looking to improve their wire drawing process.