Table of Contents

How to Properly Maintain and Care for a Vertical Wire Drop Coilers

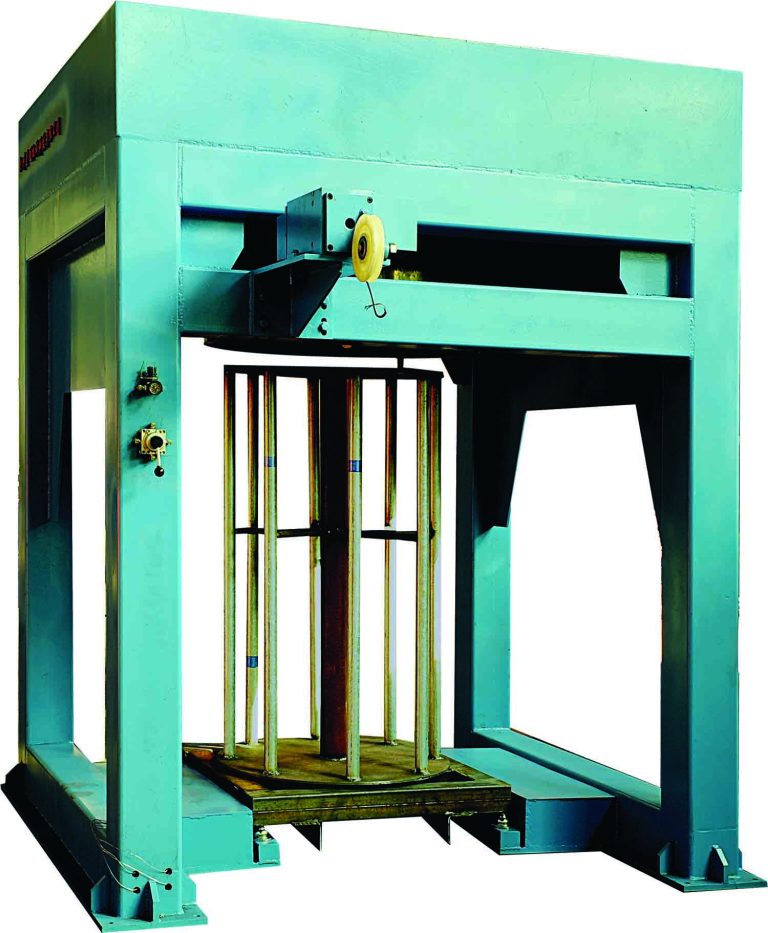

A vertical wire drop coiler is a crucial piece of equipment used in various industries for coiling wire efficiently and effectively. Proper maintenance and care of this machine are essential to ensure its longevity and optimal performance. In this article, we will discuss some key tips on how to properly maintain and care for a vertical wire drop coiler.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. Check for loose or damaged parts, such as belts, pulleys, and bearings, and replace them as needed. Inspect the wire guides and tensioning devices to ensure they are functioning properly. Regular maintenance checks can help prevent costly repairs and downtime.

Another important aspect of maintaining a vertical wire drop coiler is keeping it clean. Dust, dirt, and debris can accumulate on the machine over time, affecting its performance. Regularly clean the machine with a soft brush or cloth to remove any buildup. Pay special attention to the wire guides and tensioning devices, as these areas are prone to collecting debris.

In addition to regular cleaning, it is important to lubricate the moving parts of the machine to reduce friction and wear. Use a high-quality lubricant recommended by the manufacturer and apply it to the bearings, pulleys, and other moving parts. Be sure to follow the manufacturer’s guidelines for lubrication frequency and amount to avoid over-lubrication.

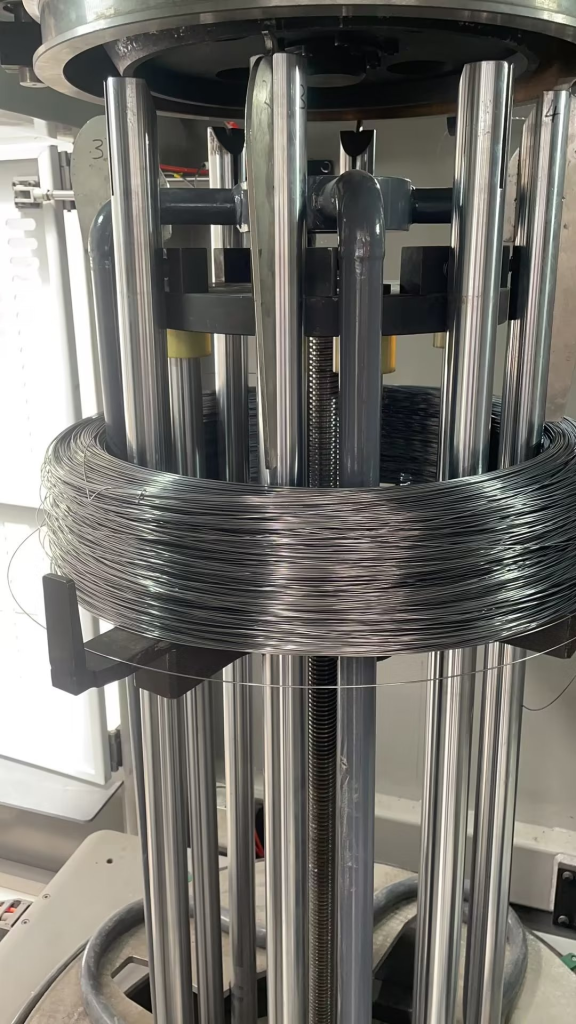

Proper tensioning of the wire is crucial for the smooth operation of a Vertical Drop Coiler. Check the tension regularly and adjust it as needed to ensure the wire is coiled correctly. Improper tensioning can lead to wire breakage and other issues, so it is important to monitor this aspect of the machine closely.

Regularly inspect the wire guides for any signs of wear or damage. Replace any worn or damaged guides to prevent wire misalignment and ensure smooth coiling. Proper alignment of the wire guides is essential for the efficient operation of the machine.

It is also important to train operators on the proper use and maintenance of a vertical wire drop coiler. Ensure that operators are familiar with the machine’s operation manual and safety guidelines. Provide training on how to perform routine maintenance tasks and troubleshoot common issues. Proper training can help prevent accidents and prolong the life of the machine.

In conclusion, proper maintenance and care are essential for ensuring the optimal performance and longevity of a vertical wire drop coiler. Regular inspections, cleaning, lubrication, and tensioning are key aspects of maintaining this machine. By following these tips and guidelines, you can keep your vertical wire drop coiler in top condition and avoid costly repairs and downtime. Remember to train operators on the proper use and maintenance of the machine to ensure safe and efficient operation.

Tips for Choosing the Right Vertical Wire Drop Coiler for Your Specific Needs

When it comes to choosing the right vertical wire drop coiler for your specific needs, there are several factors to consider. A vertical wire drop coiler is a machine used to coil wire vertically, typically in a controlled manner to ensure proper winding and storage. These machines are commonly used in industries such as manufacturing, construction, and telecommunications.

One of the first things to consider when choosing a vertical single block wire drop coiler is the type of wire you will be coiling. Different machines are designed to handle different types and sizes of wire, so it is important to choose a coiler that is compatible with the wire you will be working with. Additionally, consider the speed at which you will need to coil the wire, as some machines are capable of higher speeds than others.

Another important factor to consider is the size of the coils you will need to produce. Some vertical wire drop coilers are capable of producing larger coils, while others are better suited for smaller coils. Consider the space you have available for storing the coils, as well as any specific requirements for the size of the coils in your industry.

It is also important to consider the level of automation you require in a vertical wire drop coiler. Some machines are fully automated, with features such as automatic tension control and coil counting, while others require more manual operation. Consider your specific needs and the level of automation that will best suit your operation.

When choosing a vertical wire drop coiler, it is important to consider the durability and reliability of the machine. Look for a coiler that is built with high-quality materials and components, as well as a reputable manufacturer with a track record of producing reliable machines. Consider the maintenance requirements of the machine, as well as the availability of spare parts and technical support.

In addition to the machine itself, consider the support and service provided by the manufacturer. Look for a company that offers training and support for operating and maintaining the coiler, as well as a warranty and service agreement. Consider the reputation of the manufacturer and their customer service record when making your decision.

Overall, choosing the right vertical wire drop coiler for your specific needs requires careful consideration of several factors. Consider the type and size of wire you will be working with, the speed and size of coils you need to produce, the level of automation required, and the durability and reliability of the machine. Additionally, consider the support and service provided by the manufacturer. By taking these factors into account, you can choose a vertical wire drop coiler that will meet your specific needs and provide reliable performance for years to come.