Table of Contents

Tips for Maintaining Vertical Single Block Wire Drawing Machines

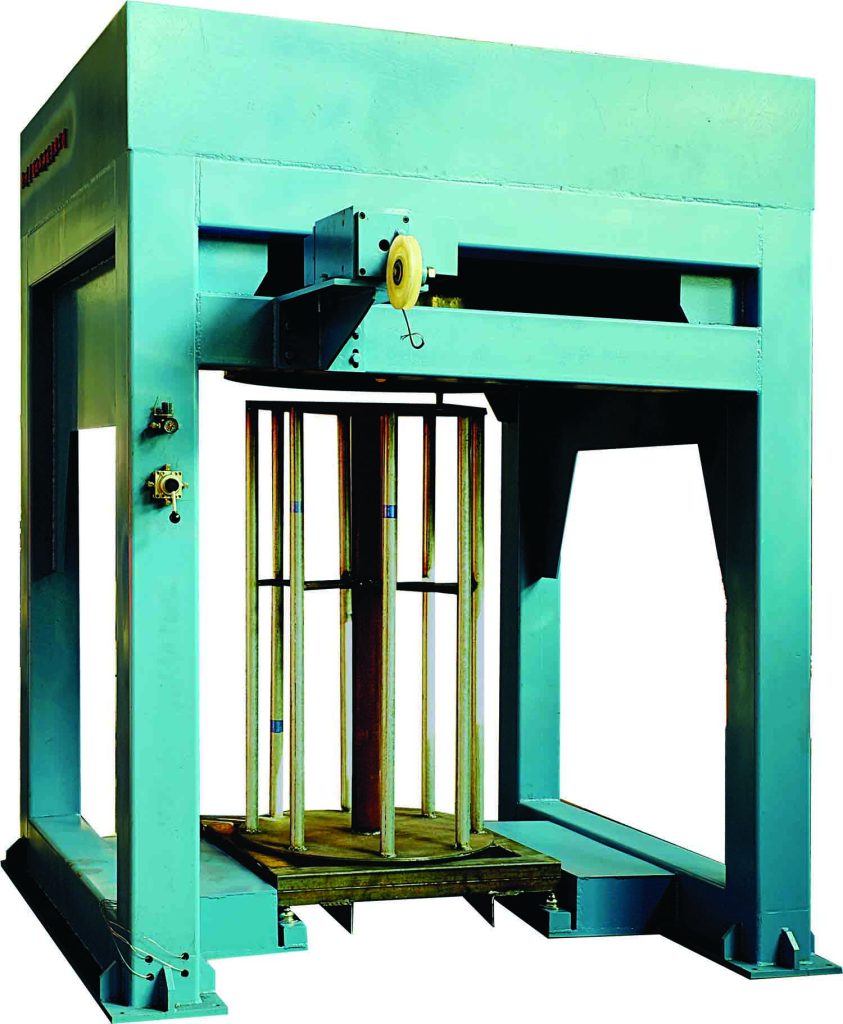

Vertical single block wire drawing machine is essential equipment in the wire manufacturing industry. These machines are used to draw wire through a series of dies to reduce its diameter and improve its quality. Proper maintenance of these machines is crucial to ensure their optimal performance and longevity. In this article, we will discuss some tips for maintaining vertical single block wire drawing machines.

One of the most important aspects of maintaining a vertical single block wire drawing machine is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased wear and tear. It is essential to clean the machine regularly using a soft brush or cloth to remove any buildup. Additionally, lubricating the machine’s moving parts with a suitable lubricant will help reduce friction and prevent premature wear.

Another crucial aspect of maintaining a vertical single block wire drawing machine is inspecting its components regularly. Check for any signs of wear or damage, such as cracks, dents, or corrosion. Replace any worn or damaged parts immediately to prevent further damage to the machine. It is also essential to check the machine’s alignment and adjust it if necessary to ensure smooth operation.

Proper tension control is vital for the efficient operation of a vertical single block wire drawing machine. Check the tension of the wire regularly and adjust it as needed to prevent breakage or slippage. Additionally, ensure that the machine’s speed is set correctly to avoid overheating and excessive wear on the wire.

Regularly monitoring the machine’s performance is essential for detecting any issues early on. Keep an eye on the machine’s output quality, speed, and noise levels. Any sudden changes in these parameters could indicate a problem that needs to be addressed promptly. It is also a good idea to keep a maintenance log to track the machine’s performance and any maintenance tasks performed.

Proper training of operators is crucial for the efficient operation and maintenance of a vertical single block wire drawing machine. Ensure that all operators are trained on how to use the machine correctly and safely. Provide them with the necessary tools and resources to perform maintenance tasks effectively. Regularly review and update training materials to keep operators informed of best practices and safety procedures.

In conclusion, maintaining a vertical single block wire drawing machine is essential for ensuring its optimal performance and longevity. Regular cleaning, inspection, tension control, and monitoring of the machine’s performance are key aspects of maintenance. Proper training of operators is also crucial for the efficient operation of the machine. By following these tips, you can keep your vertical single block wire drawing machine in top condition and maximize its productivity.

Advantages of Using Vertical Single Block Wire Drawing Machines

Vertical single block wire drawing machines are a crucial piece of equipment in the wire manufacturing industry. These machines are designed to efficiently draw wire through a series of dies to reduce its diameter and improve its quality. In this article, we will discuss the advantages of using vertical single block wire drawing machines in wire production.

One of the main advantages of Inverted vertical drawing machine is their compact design. These machines are typically smaller in size compared to traditional horizontal wire drawing machines, making them ideal for facilities with limited space. The vertical design also allows for easier integration into existing production lines, maximizing efficiency and productivity.

In addition to their compact design, vertical single block wire drawing machines offer superior control over the wire drawing process. The vertical orientation of the machine allows for better alignment of the wire with the dies, resulting in more precise and consistent drawing. This level of control is essential for producing high-quality wire with uniform diameter and surface finish.

Another advantage of vertical single block wire drawing machines is their versatility. These machines are capable of drawing a wide range of wire sizes and materials, making them suitable for a variety of applications. Whether you are producing fine wire for electronics or heavy-duty wire for construction, a vertical single block wire drawing machine can meet your needs.

Furthermore, vertical single block wire drawing machines are known for their energy efficiency. These machines are designed to minimize energy consumption while maintaining high productivity levels. By reducing energy costs, wire manufacturers can improve their bottom line and remain competitive in the market.

Vertical single block wire drawing machines also offer easy maintenance and servicing. The vertical design allows for quick access to the dies and other components, making it easier to perform routine maintenance and repairs. This results in less downtime and increased overall equipment reliability.

Additionally, vertical single block wire drawing machines are known for their durability and longevity. These machines are built to withstand the rigors of continuous operation, ensuring years of reliable performance. With proper maintenance and care, a vertical single block wire drawing machine can provide consistent results for many years to come.

In conclusion, vertical single block wire drawing machines offer numerous advantages for wire manufacturers. From their compact design and superior control to their versatility and energy efficiency, these machines are a valuable asset in the wire production process. With easy maintenance and long-lasting durability, vertical single block wire drawing machines are a smart investment for any wire manufacturing facility looking to improve efficiency and quality.