Table of Contents

Advantages of Using Vertical Drop Coiler for Take-Up High Carbon Steel Wire

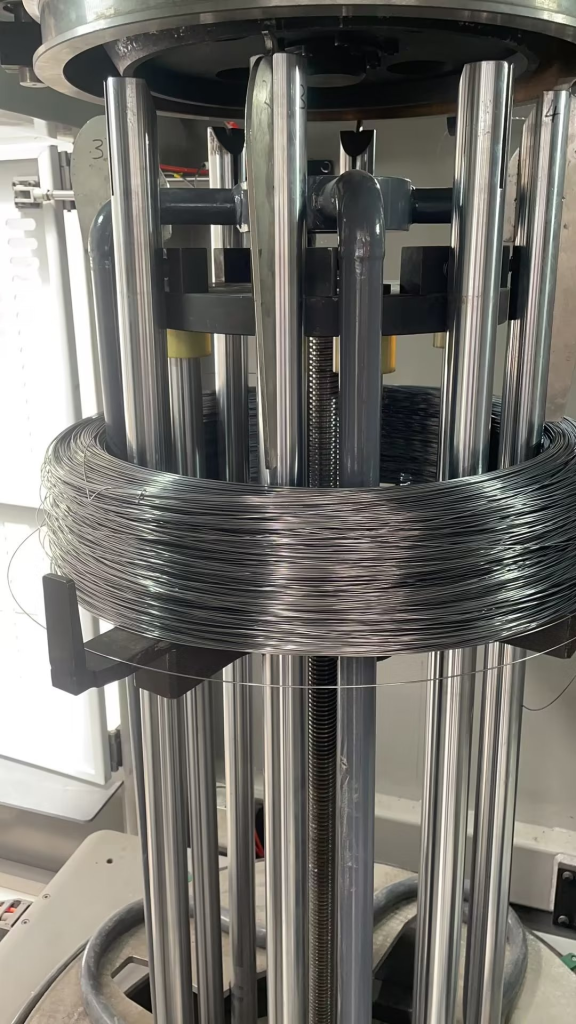

High carbon steel wire is a versatile material that is used in a wide range of industries, from automotive to construction. When it comes to manufacturing high carbon steel wire, one of the key processes is coiling the wire onto a spool or reel for storage and transportation. Traditionally, horizontal coilers have been used for this purpose, but in recent years, vertical drop coilers have become increasingly popular due to their many advantages.

One of the main advantages of using a vertical drop coiler for take-up high carbon steel wire is its space-saving design. Unlike horizontal coilers, which require a large amount of floor space to accommodate the coiling process, vertical drop coilers can be installed in a much smaller footprint. This is especially beneficial for manufacturers with limited space in their facilities, allowing them to maximize their production capacity without sacrificing valuable floor space.

In addition to space savings, Vertical Wire Drop Coiler also offer increased efficiency in the coiling process. The vertical design allows for a more controlled and consistent coiling process, resulting in higher quality coils with minimal defects. This is crucial when working with high carbon steel wire, as any imperfections in the coil can compromise the integrity of the wire and lead to costly rework or scrap.

Furthermore, vertical drop coilers are designed to handle high-speed coiling operations, making them ideal for high-volume production environments. The vertical orientation of the coiler allows for faster coil transfer and spool changes, reducing downtime and increasing overall productivity. This is particularly advantageous for manufacturers looking to increase their output without sacrificing quality or reliability.

Another key advantage of using a vertical drop coiler for take-up high carbon steel wire is its versatility. Vertical drop coilers can be easily customized to accommodate different wire sizes and coil configurations, making them suitable for a wide range of applications. Whether you are coiling thin wire for electrical applications or thick wire for industrial use, a vertical drop coiler can be tailored to meet your specific requirements.

In conclusion, the use of a vertical drop coiler for take-up high carbon steel wire offers numerous advantages over traditional horizontal coilers. From space savings and increased efficiency to high-speed operation and versatility, vertical drop coilers are a valuable asset for manufacturers looking to optimize their coiling process. By investing in a vertical drop coiler, manufacturers can improve their production capabilities, reduce costs, and ultimately enhance the quality of their high carbon steel wire products.

Tips for Efficiently Operating a Vertical Drop Coiler for Take-Up High Carbon Steel Wire

A vertical drop coiler is an essential piece of equipment for efficiently taking up high carbon steel wire. This machine is designed to coil wire in a vertical orientation, allowing for a compact and organized storage solution. Operating a vertical drop coiler requires precision and attention to detail to ensure the wire is coiled correctly and safely. In this article, we will provide some tips for efficiently operating a vertical drop coiler for take-up high carbon steel wire.

First and foremost, it is important to properly set up the vertical drop coiler before beginning the coiling process. This includes adjusting the tension settings, ensuring the wire guide is aligned correctly, and checking that all safety features are in place. Taking the time to properly set up the machine will help prevent any issues during the coiling process and ensure a smooth operation.

When coiling high carbon steel wire, it is important to pay attention to the speed at which the wire is being fed into the coiler. High carbon steel wire is known for its strength and durability, but it can also be prone to tangling if not handled properly. By controlling the speed at which the wire is fed into the coiler, you can prevent tangles and ensure a consistent coil.

Additionally, it is important to monitor the tension of the wire as it is being coiled. High carbon steel wire can be sensitive to tension changes, so it is important to keep a close eye on the tension settings throughout the coiling process. Adjusting the tension as needed will help prevent any issues with the wire and ensure a high-quality coil.

Another important tip for efficiently operating a vertical drop coiler is to regularly inspect the machine for any signs of wear or damage. This includes checking the bearings, gears, and other moving parts for any signs of wear. Regular maintenance and inspections will help prevent any unexpected breakdowns and ensure the machine is operating at its best.

In addition to regular maintenance, it is also important to keep the coiling area clean and free of debris. High carbon steel wire can be prone to picking up dirt and debris, which can affect the quality of the coil. By keeping the coiling area clean and free of debris, you can ensure a high-quality coil every time.

Lastly, it is important to follow all safety guidelines and procedures when operating a vertical drop coiler. This includes wearing appropriate safety gear, such as gloves and safety glasses, and following all safety protocols outlined in the machine’s manual. By prioritizing safety, you can prevent accidents and ensure a safe working environment for yourself and others.

In conclusion, efficiently operating a vertical drop coiler for take-up high carbon steel wire requires attention to detail, proper setup, and regular maintenance. By following these tips, you can ensure a smooth and efficient coiling process and produce high-quality coils every time. Remember to pay attention to tension, speed, and cleanliness, and always prioritize safety when operating the machine. With these tips in mind, you can efficiently operate a vertical drop coiler for take-up high carbon steel wire with confidence.