Merits of Using a Wire Drawing Machine for Low Carbon Steel Wire

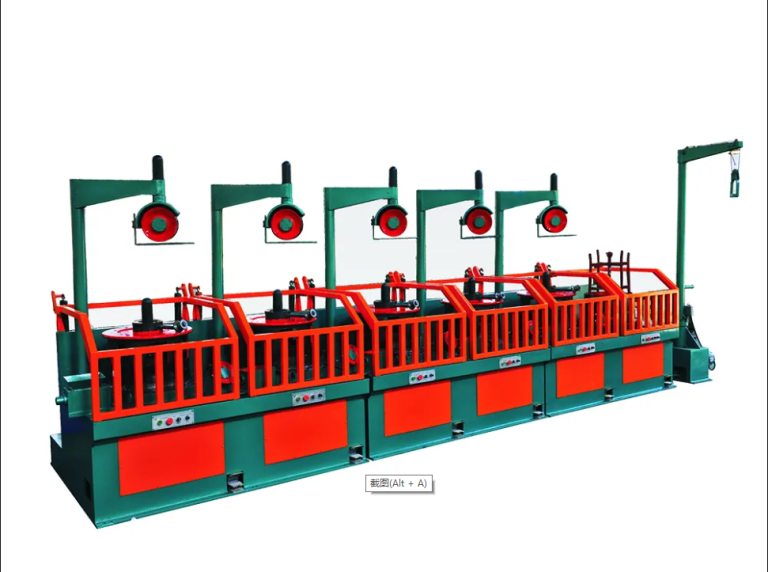

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various types of wire, including low carbon steel wire. One of the key machines used in this process is the straight line wire drawing machine. This machine offers several benefits when it comes to drawing low carbon steel wire.

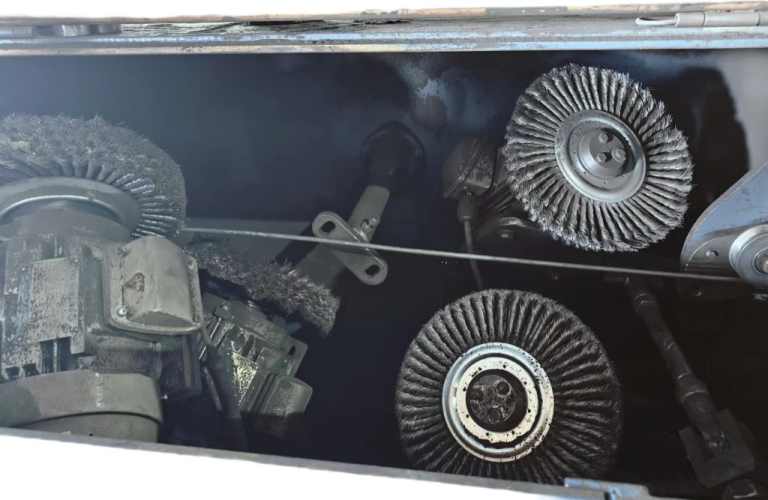

One of the main advantages of using a Straight Line Wire Drawing Machine For Low Carbon Steel Wire is its ability to produce wire with consistent diameter and surface finish. The machine is designed to pull the wire through a series of dies in a straight line, ensuring that the wire is drawn evenly and smoothly. This results in a high-quality wire that meets the required specifications for strength and durability.

In addition to producing high-quality wire, a straight line wire drawing machine is also highly efficient. The machine is capable of drawing wire at high speeds, allowing for increased production rates. This can help manufacturers meet tight deadlines and fulfill customer orders in a timely manner. Furthermore, the machine is designed to operate continuously, minimizing downtime and maximizing productivity.

Another benefit of using a straight line wire drawing machine for low carbon steel wire is its versatility. The machine can be easily adjusted to accommodate different wire sizes and types of steel. This flexibility allows manufacturers to produce a wide range of wire products to meet the needs of various industries. Whether it’s for construction, automotive, or manufacturing applications, a straight line wire drawing machine can handle the job with precision and efficiency.

Furthermore, a straight line wire drawing machine is also cost-effective. The machine is designed to minimize waste and reduce material loss during the drawing process. This can result in significant cost savings for manufacturers, as they can produce more wire with less raw material. Additionally, the machine requires minimal maintenance and upkeep, further reducing operating costs over time.

Overall, the benefits of using a straight line wire drawing machine for low carbon steel wire are clear. From producing high-quality wire with consistent diameter and surface finish to increasing production rates and reducing costs, this machine offers a range of advantages for manufacturers. Its efficiency, versatility, and cost-effectiveness make it an essential tool for any company looking to produce top-quality wire products for various industries.

In conclusion, a straight line wire drawing machine is a valuable asset for manufacturers working with low carbon steel wire. Its ability to produce high-quality wire efficiently and cost-effectively makes it an essential tool for meeting the demands of today’s competitive market. By investing in a straight line wire drawing machine, manufacturers can ensure that they are able to produce top-quality wire products that meet the needs of their customers and stand up to the rigors of various applications.