Table of Contents

Understand of Using a Nail Cutter in Nail Making Machine Accessories

Nail making machines are essential tools in the manufacturing industry, producing nails of various sizes and shapes efficiently. To ensure the smooth operation of these machines, it is crucial to have the right accessories, such as a nail cutter. The nail cutter is a vital component of the nail making machine, responsible for cutting the nails to the desired length. In this article, we will explore the benefits of using a nail cutter in nail making machine accessories.

One of the primary benefits of using a nail cutter in a nail making machine is precision. The nail cutter is designed to cut nails to a specific length, ensuring uniformity in the nails produced. This precision is essential in industries where consistency and quality are paramount. By using a nail cutter, manufacturers can produce nails that meet the required specifications, leading to higher customer satisfaction and increased sales.

Another benefit of using a nail cutter in a nail making machine is efficiency. The nail cutter is a fast and reliable tool that can cut nails quickly and accurately. This efficiency helps manufacturers increase their production output, reducing production time and costs. With a nail cutter, manufacturers can produce more nails in less time, allowing them to meet customer demands and stay competitive in the market.

In addition to precision and efficiency, using a nail cutter in a nail making machine also improves safety. The nail cutter is designed with safety features to prevent accidents and injuries during operation. By using a nail cutter, manufacturers can ensure the safety of their workers and reduce the risk of workplace accidents. This not only protects the well-being of employees but also helps companies avoid costly lawsuits and fines.

Furthermore, using a nail cutter in a nail making machine can extend the lifespan of the machine. The nail cutter is a durable tool that can withstand the rigors of daily use. By using a nail cutter, manufacturers can reduce wear and tear on the machine, prolonging its lifespan and reducing maintenance costs. This ultimately leads to cost savings for manufacturers and ensures the longevity of their equipment.

Overall, the benefits of using a nail cutter in nail making machine accessories are clear. From precision and efficiency to safety and durability, the nail cutter plays a crucial role in the production of high-quality nails. By investing in a nail cutter, manufacturers can improve their production processes, increase output, and ensure the safety of their workers. In today’s competitive market, having the right accessories, such as a nail cutter, is essential for success in the nail manufacturing industry.

In conclusion, the nail cutter is a valuable tool in nail making machine accessories, offering a range of benefits that can help manufacturers improve their production processes and stay ahead of the competition. By investing in a nail cutter, manufacturers can achieve precision, efficiency, safety, and durability in their nail production, ultimately leading to increased customer satisfaction and profitability.

How to Choose the Right Nail Cutter for Your Nail Making Machine

When it comes to nail making machine accessories, one of the most important components is the nail cutter. The nail cutter plays a crucial role in the nail making process, as it is responsible for cutting the wire into the desired nail length. Choosing the right nail cutter for your nail making machine is essential to ensure smooth and efficient operation.

There are several factors to consider when selecting a nail cutter for your nail making machine. The first consideration is the type of nails you will be producing. Different nail cutters are designed for specific nail types, such as common nails, finishing nails, or roofing nails. It is important to choose a nail cutter that is compatible with the type of nails you will be manufacturing.

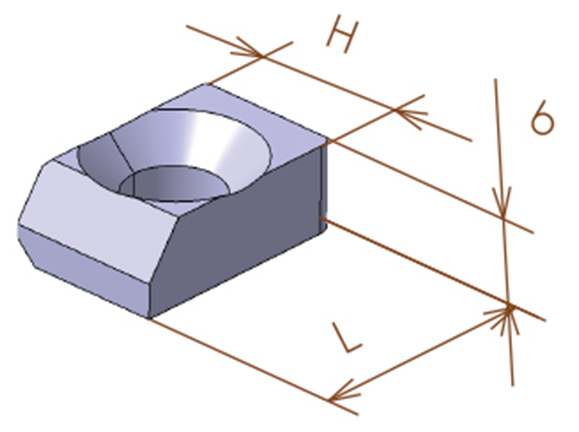

Another important factor to consider is the size of the nails you will be producing. Nail cutters come in various sizes to accommodate different nail lengths and diameters. It is important to choose a nail cutter that is suitable for the size of nails you will be manufacturing to ensure accurate and precise cutting.

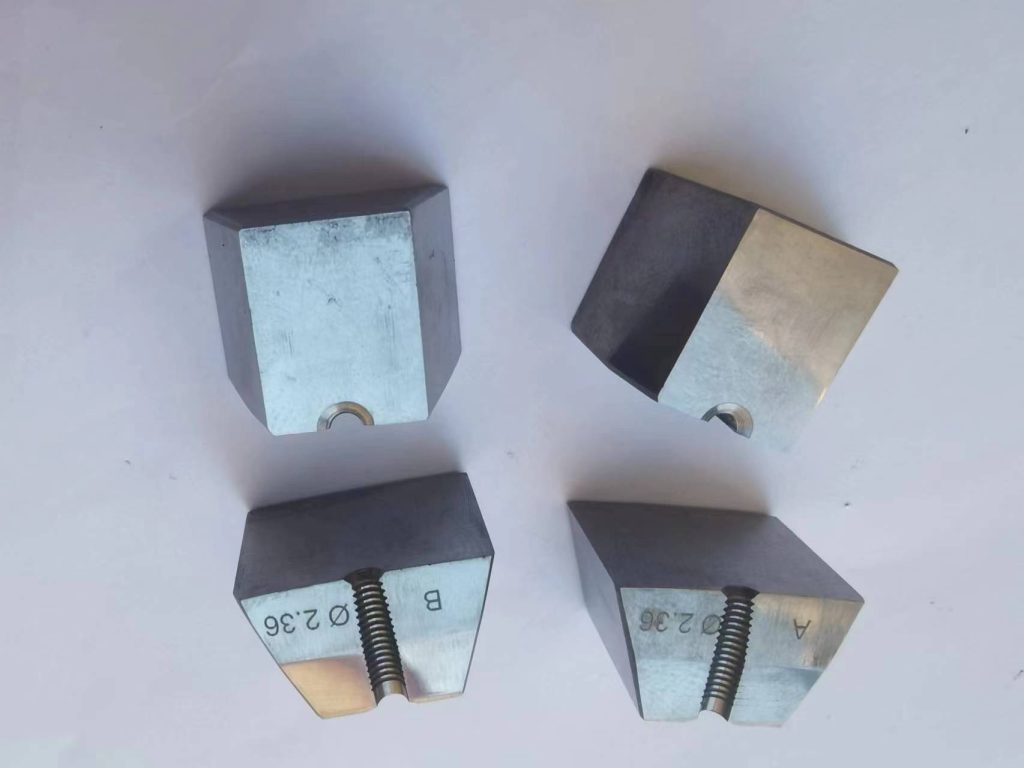

In addition to nail type and size, it is also important to consider the material of the nail cutter. Nail cutters are typically made of high-quality steel or carbide, which are durable and long-lasting. Choosing a nail cutter made of high-quality material will ensure that it can withstand the rigors of continuous use in a nail making machine.

When selecting a nail cutter for your nail making machine, it is also important to consider the cutting mechanism. Nail cutters can have different cutting mechanisms, such as guillotine cutters or rotary cutters. The cutting mechanism will affect the speed and precision of the cutting process, so it is important to choose a nail cutter with a cutting mechanism that meets your production needs.

Furthermore, it is important to consider the maintenance and sharpening requirements of the nail cutter. Some nail cutters may require regular sharpening or maintenance to ensure optimal performance. It is important to choose a nail cutter that is easy to maintain and sharpen to minimize downtime and ensure consistent cutting performance.

In conclusion, choosing the right nail cutter for your nail making machine is essential to ensure efficient and accurate nail production. Consider factors such as nail type, size, material, cutting mechanism, and maintenance requirements when selecting a nail cutter for your nail making machine. By choosing a high-quality nail cutter that meets your production needs, you can ensure smooth operation and high-quality nail production.