Table of Contents

Advantages of Rolling Ring Traverse Drive in Industrial Applications

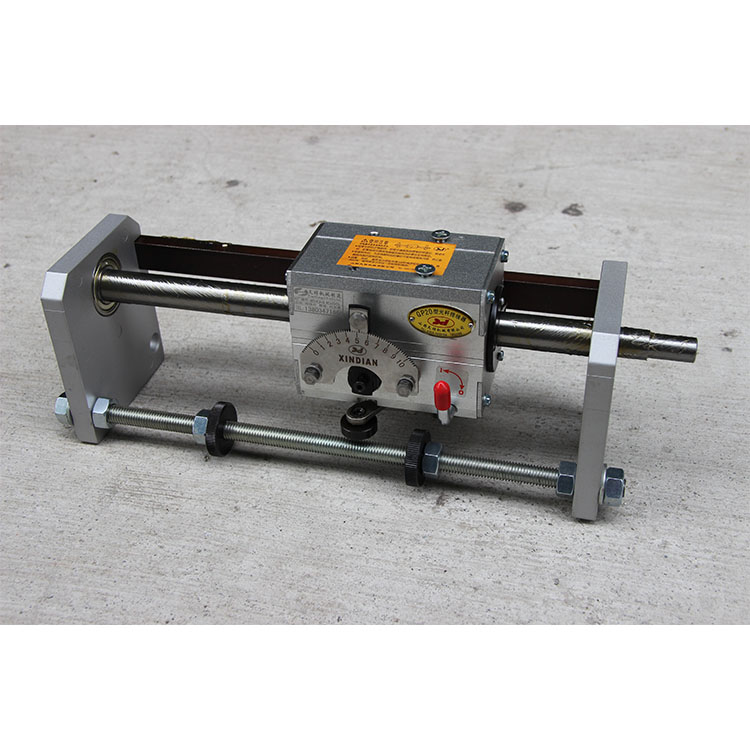

Rolling ring traverse drives are a type of linear motion drive system that is commonly used in industrial applications. These drives offer a number of advantages that make them a popular choice for a wide range of applications. In this article, we will explore some of the key advantages of rolling ring traverse drives in industrial settings.

One of the primary advantages of rolling ring traverse drives is their high level of precision. These drives are capable of providing extremely accurate and repeatable motion, making them ideal for applications that require precise positioning. This level of precision is essential in many industrial applications, such as in the manufacturing of electronic components or in the assembly of complex machinery.

Another key advantage of Rolling Ring Drive is their versatility. These drives can be easily adapted to suit a wide range of applications, making them a flexible and cost-effective solution for many industrial processes. Whether you need a drive system for a small-scale operation or a large-scale manufacturing facility, rolling ring traverse drives can be customized to meet your specific requirements.

In addition to their precision and versatility, rolling ring traverse drives are also known for their durability and reliability. These drives are designed to withstand the rigors of industrial use, making them a long-lasting and dependable choice for a wide range of applications. This reliability is essential in industrial settings, where downtime can be costly and disruptive to operations.

Rolling ring traverse drives are also known for their efficiency. These drives are designed to minimize energy consumption and reduce waste, making them a sustainable choice for environmentally conscious industries. By using a rolling ring traverse drive, you can reduce your energy costs and minimize your environmental impact, making them a smart choice for businesses looking to improve their sustainability practices.

Overall, rolling ring traverse drives offer a number of advantages that make them an attractive choice for industrial applications. From their precision and versatility to their durability and efficiency, these drives are a reliable and cost-effective solution for a wide range of industrial processes. Whether you need a drive system for a small-scale operation or a large-scale manufacturing facility, rolling ring traverse drives can be customized to meet your specific requirements. With their high level of precision, versatility, durability, and efficiency, rolling ring traverse drives are a smart choice for businesses looking to improve their industrial processes and increase their productivity.

How to Properly Maintain and Troubleshoot Rolling Ring Traverse Drives

Rolling ring traverse drives are a critical component in many industrial applications, providing precise control over the movement of materials along a linear path. These drives are commonly used in industries such as textiles, wire and cable manufacturing, and packaging. Proper maintenance and troubleshooting of rolling ring traverse drives are essential to ensure smooth operation and prevent costly downtime.

One of the most important aspects of maintaining rolling ring traverse drives is regular lubrication. Proper lubrication helps reduce friction and wear on the drive components, extending their lifespan and ensuring smooth operation. It is important to use the correct type of lubricant recommended by the drive manufacturer and to follow the recommended lubrication schedule.

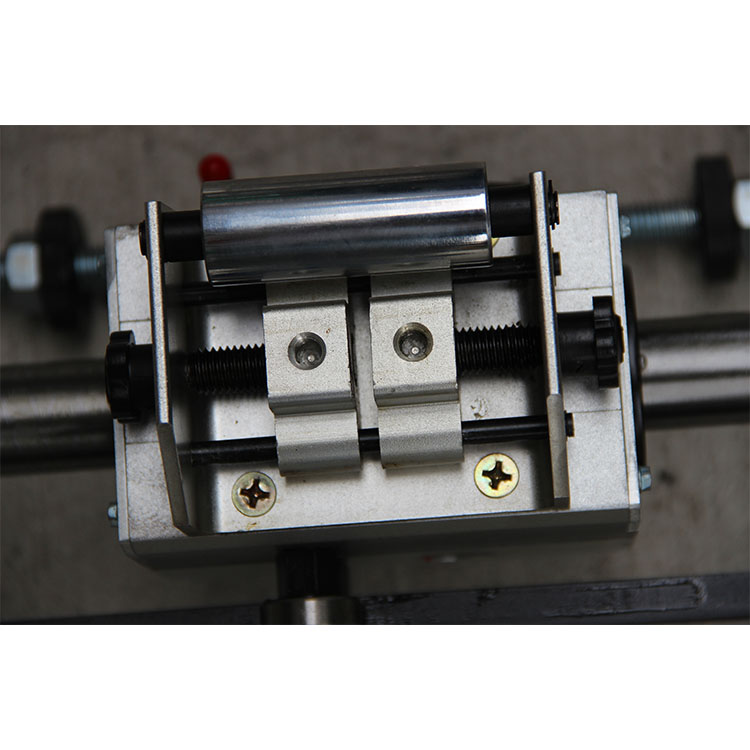

In addition to lubrication, regular inspection of the drive components is essential for detecting any signs of wear or damage. Inspect the drive belts, pulleys, and bearings for any signs of wear, such as cracks, fraying, or excessive play. Replace any worn or damaged components immediately to prevent further damage to the drive system.

Another important aspect of maintaining rolling ring traverse drives is proper tensioning of the drive belts. Over time, drive belts can stretch and lose tension, affecting the drive’s performance. Check the tension of the drive belts regularly and adjust as needed to ensure proper operation.

In the event of a malfunction or breakdown of the rolling ring traverse drive, troubleshooting is necessary to identify the root cause of the issue. One common issue with rolling ring traverse drives is misalignment of the drive components. Misalignment can cause excessive wear on the drive components and lead to premature failure. Check the alignment of the drive belts, pulleys, and bearings and make any necessary adjustments to correct the misalignment.

Another common issue with rolling ring traverse drives is belt slippage. Belt slippage can occur due to improper tensioning of the drive belts or worn drive components. Check the tension of the drive belts and replace any worn components to prevent belt slippage.

If the rolling ring traverse drive is making unusual noises or vibrations, it may indicate a problem with the drive components. Inspect the drive belts, pulleys, and bearings for any signs of wear or damage and replace any worn components to eliminate the noise or vibration.

In conclusion, proper maintenance and troubleshooting of rolling ring traverse drives are essential to ensure smooth operation and prevent costly downtime. Regular lubrication, inspection of drive components, proper tensioning of drive belts, and troubleshooting of common issues are key steps in maintaining rolling ring traverse drives. By following these maintenance practices, you can extend the lifespan of your rolling ring traverse drive and ensure reliable performance in your industrial applications.