Table of Contents

Maintenance Tips For Ensuring Longevity Of Your OTO Type Wire Drawing Machine

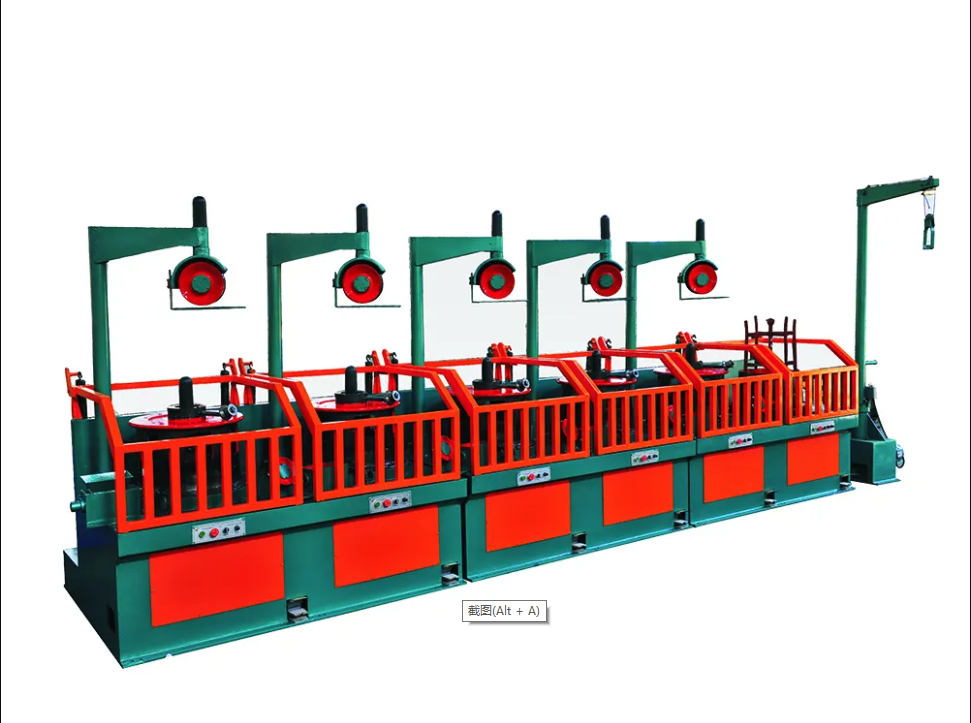

Wire drawing machines are essential equipment in the manufacturing industry, particularly in the production of wires of various diameters. One popular type of wire drawing machine is the OTO type, known for its efficiency and reliability. To ensure the longevity of your OTO type wire drawing machine, proper maintenance is crucial. In this article, we will discuss some maintenance tips that can help you maximize the lifespan of your machine.

First and foremost, regular cleaning of the machine is essential. Dust, dirt, and debris can accumulate on the machine’s components, leading to increased wear and tear. Use a soft brush or cloth to remove any buildup on the machine’s surfaces. Pay special attention to the wire drawing dies, as any debris on these components can affect the quality of the wire produced.

In addition to cleaning, lubrication is another key aspect of machine maintenance. Proper lubrication of the machine’s moving parts can help reduce friction and prevent premature wear. Be sure to use the recommended lubricants for each component, as using the wrong type of lubricant can cause damage to the machine.

Inspecting the machine regularly is also important for identifying any potential issues before they escalate. Check for loose or damaged parts, unusual noises, or any signs of wear. Addressing these issues promptly can prevent more significant problems down the line.

Another crucial maintenance tip is to monitor the machine’s operating temperature. Overheating can cause damage to the machine’s components and affect its performance. Ensure that the machine is operating within the recommended temperature range and take steps to cool it down if necessary.

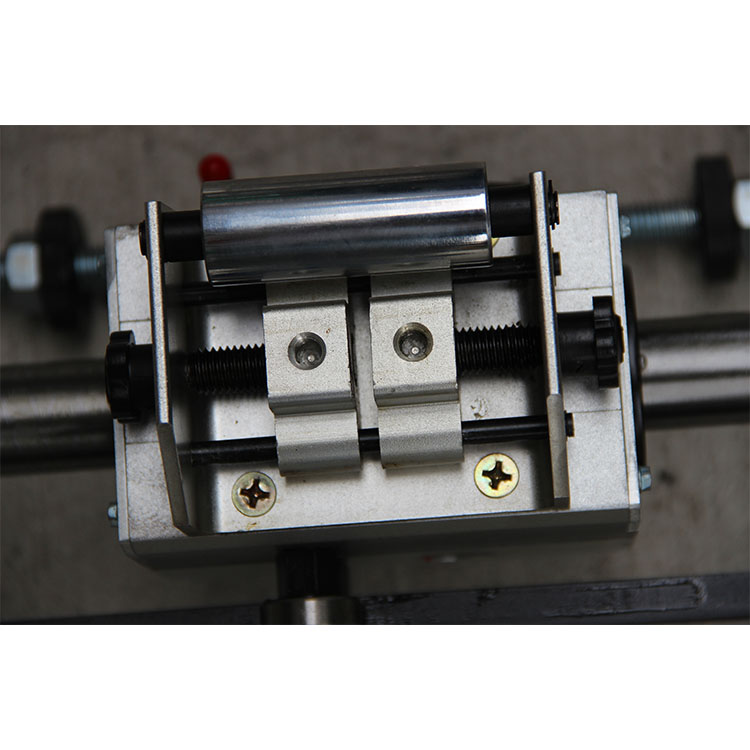

Furthermore, proper tensioning of the wire drawing dies is essential for producing high-quality wire. Check the tension regularly and adjust it as needed to ensure consistent results. Improper tensioning can lead to wire breakage and other issues that can affect the machine’s performance.

Regular calibration of the machine is also important for maintaining its accuracy and efficiency. Over time, the machine’s settings may drift, leading to deviations in wire diameter or other parameters. Calibrating the machine regularly can help ensure that it is operating at peak performance.

Lastly, training your operators on proper machine maintenance procedures is crucial for ensuring the longevity of your OTO type wire drawing machine. Make sure that your staff is familiar with the machine’s maintenance requirements and protocols. Encourage them to report any issues or concerns promptly so that they can be addressed in a timely manner.

In conclusion, proper maintenance is essential for ensuring the longevity of your OTO type wire drawing machine. By following these maintenance tips, you can maximize the lifespan of your machine and ensure that it continues to operate efficiently for years to come. Remember to clean, lubricate, inspect, monitor, tension, calibrate, and train to keep your machine in top condition.

How To Choose The Right OTO Type Wire Drawing Machine For Your Business

When it comes to choosing the right OTO type wire drawing machine for your business, there are several factors to consider. OTO type wire drawing machines are essential equipment for businesses involved in the production of wires and cables. These machines are used to reduce the diameter of wire rods and improve their surface finish. With so many options available on the market, it can be overwhelming to select the best machine for your specific needs. In this article, we will discuss some key considerations to keep in mind when choosing an OTO type wire drawing machine for sale.

First and foremost, it is important to consider the production capacity of the machine. The production capacity of a wire drawing machine is typically measured in terms of the maximum wire diameter it can handle and the number of drafts it can perform. It is essential to choose a machine that can meet your production requirements without compromising on quality. Consider the volume of wire rods you need to process on a daily basis and choose a machine that can handle that workload efficiently.

Another important factor to consider is the speed of the machine. The speed of an OTO type wire drawing machine is measured in terms of meters per minute (m/min). Higher speeds can increase productivity and reduce production time. However, it is crucial to strike a balance between speed and quality. A machine that operates at too high a speed may compromise the quality of the finished product. Consider your production requirements and choose a machine that offers the right balance of speed and quality.

In addition to production capacity and speed, it is essential to consider the quality of the finished product. The surface finish and diameter accuracy of the wire produced by the machine are crucial factors to consider. Look for a machine that offers precise control over the drawing process to ensure consistent quality. Consider the materials you will be working with and choose a machine that is suitable for those materials.

Furthermore, it is important to consider the maintenance requirements of the machine. Regular maintenance is essential to ensure the smooth operation of the machine and prevent breakdowns. Look for a machine that is easy to maintain and comes with a comprehensive maintenance plan. Consider the availability of spare parts and technical support when choosing a machine.

Lastly, consider the reputation of the manufacturer when choosing an OTO type wire drawing machine for sale. Look for a reputable manufacturer with a track record of producing high-quality machines. Read reviews and testimonials from other customers to gauge the reliability and performance of the machine. Choose a manufacturer that offers a warranty and after-sales support to ensure peace of mind.

In conclusion, choosing the right OTO type wire drawing machine for your business is a crucial decision that can impact the efficiency and quality of your production process. Consider factors such as production capacity, speed, quality, maintenance requirements, and manufacturer reputation when making your decision. By taking the time to research and evaluate your options, you can select a machine that meets your specific needs and helps your business thrive.