Table of Contents

Benefits of Using a Mechanical Wire Descaler with Wire Brushing Unit

A mechanical wire descaler with a wire brushing unit is a valuable tool in various industries that rely on the use of wire products. This innovative machine offers numerous benefits that can improve efficiency, productivity, and overall product quality. In this article, we will explore the advantages of using a mechanical wire descaler with a wire brushing unit.

One of the primary benefits of using a mechanical wire descaler with a wire brushing unit is the ability to remove rust, scale, and other surface contaminants from wire products. These contaminants can negatively impact the quality of the wire and compromise its performance. By using a mechanical wire descaler with a wire brushing unit, manufacturers can ensure that their wire products are clean and free from any impurities that could affect their functionality.

In addition to improving the quality of wire products, a mechanical wire descaler with a wire brushing unit can also help to extend the lifespan of wire products. Rust and scale can cause wire products to deteriorate over time, leading to premature failure and costly replacements. By regularly descaling and brushing wire products, manufacturers can prevent corrosion and prolong the lifespan of their wire products, saving time and money in the long run.

Furthermore, a mechanical wire descaler with a wire brushing unit can also improve the efficiency of the wire production process. By automating the descaling and brushing process, manufacturers can reduce the amount of time and labor required to clean wire products manually. This can lead to increased productivity and lower production costs, ultimately improving the overall profitability of the manufacturing operation.

Another benefit of using a mechanical wire descaler with a wire brushing unit is the ability to achieve a consistent finish on wire products. Manual descaling and brushing can result in uneven finishes, which can affect the appearance and performance of wire products. By using a mechanical wire descaler with a wire brushing unit, manufacturers can ensure that all wire products have a uniform finish, enhancing their aesthetic appeal and functionality.

Additionally, a mechanical wire descaler with a wire brushing unit can also improve workplace safety. Manual descaling and brushing can be a hazardous task, exposing workers to sharp edges and potentially harmful chemicals. By automating the descaling and brushing process, manufacturers can reduce the risk of injury to their employees and create a safer working environment.

In conclusion, a mechanical wire descaler with a wire brushing unit offers numerous benefits for manufacturers in industries that rely on wire products. From improving product quality and extending the lifespan of wire products to increasing efficiency and ensuring workplace safety, this innovative machine is a valuable tool that can help manufacturers achieve their production goals. By investing in a mechanical wire descaler with a wire brushing unit, manufacturers can enhance their manufacturing processes and ultimately improve their bottom line.

How to Properly Maintain and Clean a Mechanical Wire Descaler with Wire Brushing Unit

Maintaining and cleaning a mechanical wire descaler with a wire brushing unit is essential to ensure its optimal performance and longevity. Regular maintenance not only extends the lifespan of the equipment but also helps in preventing costly repairs and downtime. In this article, we will discuss the steps involved in properly maintaining and cleaning a mechanical wire descaler with a wire brushing unit.

First and foremost, it is important to follow the manufacturer’s guidelines for maintenance and cleaning. These guidelines are designed to help you get the most out of your equipment and ensure its proper functioning. Make sure to read the user manual thoroughly and familiarize yourself with the recommended maintenance schedule.

One of the key components of a mechanical wire descaler with a wire brushing unit is the wire brush itself. Over time, the wire brush can become worn out or clogged with debris, which can affect its performance. It is important to regularly inspect the wire brush and replace it if necessary. Most manufacturers recommend replacing the wire brush after a certain number of operating hours to ensure optimal performance.

In addition to replacing the wire brush, it is also important to clean the wire brushing unit regularly. Dust, dirt, and debris can accumulate in the unit, affecting its performance. To clean the wire brushing unit, first, disconnect the power source and remove any debris from the unit using a brush or vacuum cleaner. Next, wipe down the unit with a damp cloth to remove any remaining dirt or dust.

Another important aspect of maintaining a mechanical wire descaler with a wire brushing unit is lubrication. Proper lubrication helps reduce friction and wear on the moving parts of the equipment. Make sure to use the recommended lubricant and apply it to the moving parts according to the manufacturer’s guidelines. Regular lubrication can help extend the lifespan of the equipment and ensure smooth operation.

In addition to regular maintenance, it is also important to inspect the equipment for any signs of wear or damage. Check for loose or damaged parts, worn-out components, and any other issues that may affect the performance of the equipment. If you notice any problems, make sure to address them promptly to prevent further damage.

Proper storage is also important when it comes to maintaining a mechanical wire descaler with a wire brushing unit. Store the equipment in a clean, dry, and well-ventilated area to prevent rust and corrosion. Make sure to cover the equipment when not in use to protect it from dust and debris.

In conclusion, proper maintenance and cleaning are essential for ensuring the optimal performance and longevity of a mechanical wire descaler with a wire brushing unit. By following the manufacturer’s guidelines, regularly inspecting and cleaning the equipment, and addressing any issues promptly, you can extend the lifespan of the equipment and prevent costly repairs. Remember, a well-maintained wire descaler will not only save you time and money but also ensure smooth and efficient operation.

Comparison of Different Types of Mechanical Wire Descalers with Wire Brushing Units

Mechanical wire descalers with wire brushing units are essential tools in various industries for removing scale, rust, and other contaminants from metal wires. These machines are designed to improve the quality of the wire surface, ensuring better adhesion of coatings and enhancing overall product performance. In this article, we will compare different types of mechanical wire descalers with wire brushing units to help you choose the right one for your specific needs.

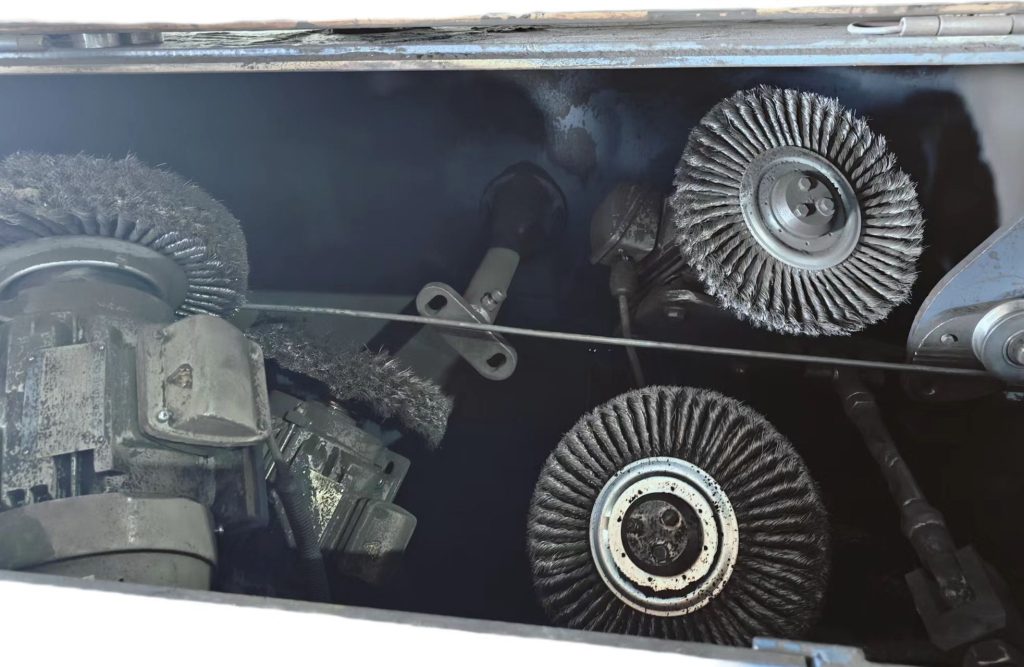

One of the most common types of mechanical wire descalers with wire brushing units is the rotary wire brush descaler. This machine features a rotating wire brush that effectively removes scale and other contaminants from the wire surface. The wire is fed through the machine, where it comes into contact with the rotating brush, which cleans the wire as it passes through. Rotary wire brush descalers are suitable for a wide range of wire diameters and can be adjusted to accommodate different wire sizes.

Another type of mechanical wire descaler with a wire brushing unit is the roller descaler. This machine features a series of rollers that press against the wire, removing scale and other contaminants. The wire is fed through the machine, where it passes between the rollers, which clean the wire surface. Roller descalers are ideal for high-volume production environments and can handle a wide range of wire sizes.

In addition to rotary and roller descalers, there are also abrasive wire brushing units that can be used in conjunction with mechanical wire descalers. These units feature abrasive wire brushes that effectively remove scale and other contaminants from the wire surface. The wire is fed through the machine, where it comes into contact with the abrasive brushes, which clean the wire as it passes through. Abrasive wire brushing units are ideal for removing tough scale and rust from wire surfaces.

When choosing a mechanical wire descaler with a wire brushing unit, it is essential to consider factors such as wire diameter, production volume, and the type of contaminants being removed. Rotary wire brush descalers are suitable for a wide range of wire sizes and are ideal for applications where a high level of cleaning is required. Roller descalers are best suited for high-volume production environments and can handle a wide range of wire sizes. Abrasive wire brushing units are ideal for removing tough scale and rust from wire surfaces and are suitable for applications where a more aggressive cleaning method is needed.

In conclusion, mechanical wire descalers with wire brushing units are essential tools for improving the quality of wire surfaces in various industries. By comparing different types of mechanical wire descalers, you can choose the right machine for your specific needs. Whether you need a rotary wire brush descaler, a roller descaler, or an abrasive wire brushing unit, there is a machine available to meet your requirements. Invest in a mechanical wire descaler with a wire brushing unit today to enhance the quality of your wire products and improve overall production efficiency.