Table of Contents

Tips for Maximizing Efficiency with an Inverted vertical drawing machine

In the world of manufacturing and industrial production, efficiency is key. Companies are constantly looking for ways to streamline their processes and maximize output while minimizing waste and downtime. One tool that has become increasingly popular in recent years is the inverted vertical drawing machine.

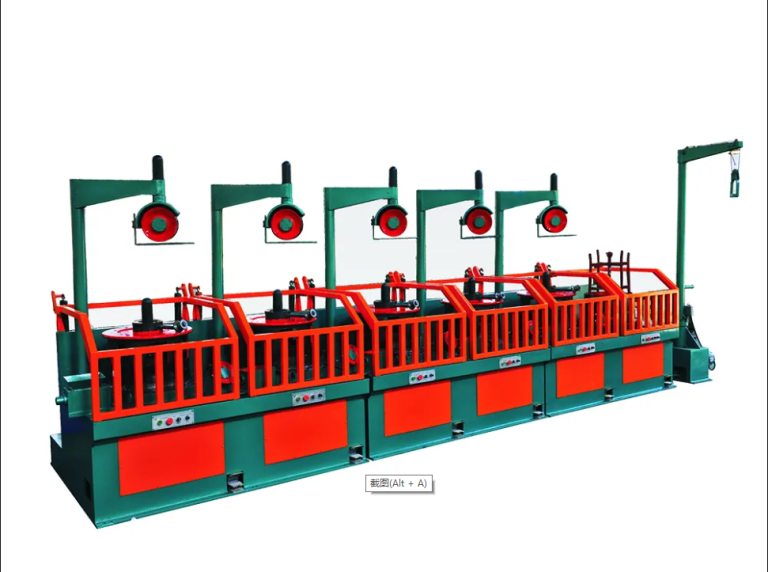

This innovative machine is used to draw wire or tubing vertically, rather than horizontally as is traditionally done. By flipping the process on its head, so to speak, manufacturers are able to achieve higher speeds and greater precision in their drawing operations. However, in order to truly maximize the efficiency of an inverted vertical drawing machine, there are a few key tips to keep in mind.

First and foremost, it is essential to ensure that the machine is properly calibrated and maintained. Like any piece of equipment, an inverted vertical drawing machine requires regular upkeep to ensure that it is operating at peak performance. This includes checking and adjusting the tension of the drawing dies, lubricating moving parts, and monitoring the speed and feed rates to ensure that they are optimized for the material being drawn.

In addition to regular maintenance, it is also important to carefully monitor the quality of the wire or tubing being produced. This can be done through regular inspections and testing, as well as by implementing quality control measures throughout the production process. By catching any issues early on, manufacturers can avoid costly rework and ensure that their products meet the necessary specifications.

Another key tip for maximizing efficiency with an inverted Vertical Single Block Wire Drawing Machine is to carefully consider the design of the dies being used. The shape and size of the dies can have a significant impact on the quality and speed of the drawing process, so it is important to choose dies that are well-suited to the material being drawn. Additionally, using dies made from high-quality materials can help to extend their lifespan and reduce the need for frequent replacements.

One of the biggest advantages of an inverted vertical drawing machine is its ability to draw multiple wires or tubes simultaneously. This can greatly increase productivity and reduce the overall production time, but it is important to carefully plan and coordinate the drawing process to ensure that each wire or tube is being drawn at the correct speed and tension. By using a synchronized control system, manufacturers can ensure that all of the wires or tubes are being drawn consistently and accurately.

Finally, it is important to invest in training for operators and technicians who will be working with the inverted vertical drawing machine. Proper training can help to prevent accidents and injuries, as well as ensure that the machine is being used to its full potential. By providing ongoing education and support for employees, manufacturers can help to maximize the efficiency and effectiveness of their production processes.

In conclusion, an inverted vertical drawing machine can be a valuable tool for manufacturers looking to increase efficiency and productivity in their drawing operations. By following these tips and best practices, companies can ensure that they are getting the most out of their machine and producing high-quality products in a timely manner. With careful planning, maintenance, and training, an inverted vertical drawing machine can help to take production to the next level.

Benefits of Using an Inverted Vertical Drawing Machine

An inverted vertical drawing machine is a specialized piece of equipment used in various industries for drawing wire or tubing. This machine is designed to operate in a vertical orientation, with the drawing die located at the top of the machine and the spool of material at the bottom. The material is fed through the die and pulled upwards by a series of rollers, resulting in a drawn product that is longer and thinner than the original material.

One of the key benefits of using an inverted vertical drawing machine is its ability to produce high-quality drawn products with consistent dimensions. The vertical orientation of the machine allows for better control over the drawing process, resulting in a more uniform product. This is especially important in industries where precision is crucial, such as the medical or aerospace sectors.

Another advantage of using an inverted vertical drawing machine is its versatility. These machines can be used to draw a wide range of materials, including metals, plastics, and composites. This makes them suitable for a variety of applications, from producing fine wire for electronics to creating tubing for plumbing systems.

In addition to their precision and versatility, inverted vertical drawing machines are also known for their efficiency. These machines are designed to operate at high speeds, allowing for rapid production of drawn products. This can help companies increase their output and meet tight production deadlines.

Furthermore, inverted vertical drawing machines are relatively easy to operate and maintain. Most machines come equipped with user-friendly controls and are designed for minimal downtime. This can help companies reduce their operating costs and improve overall productivity.

Overall, the benefits of using an inverted vertical drawing machine are clear. These machines offer precision, versatility, efficiency, and ease of operation, making them an ideal choice for companies looking to produce high-quality drawn products. Whether you are in the medical, aerospace, or any other industry that requires precision drawing, an inverted vertical drawing machine can help you meet your production needs.

In conclusion, an inverted vertical drawing machine is a valuable piece of equipment that offers numerous benefits to companies in various industries. From its ability to produce high-quality drawn products with consistent dimensions to its versatility and efficiency, this machine is a valuable asset for any company looking to improve their drawing processes. If you are in need of a reliable and efficient drawing machine, consider investing in an inverted vertical drawing machine for your production needs.