Merits of Using a Horizontal Spooling Machine

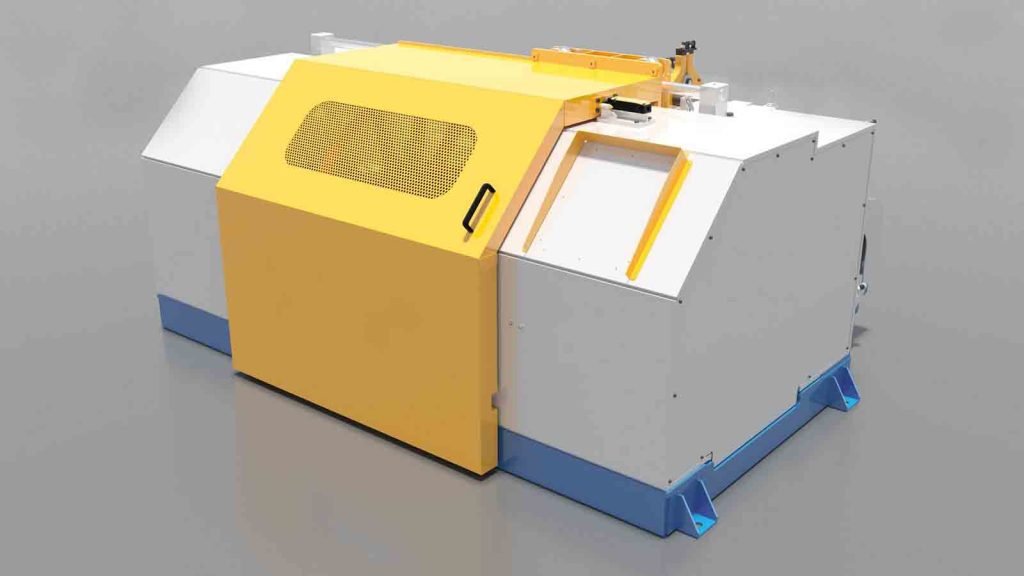

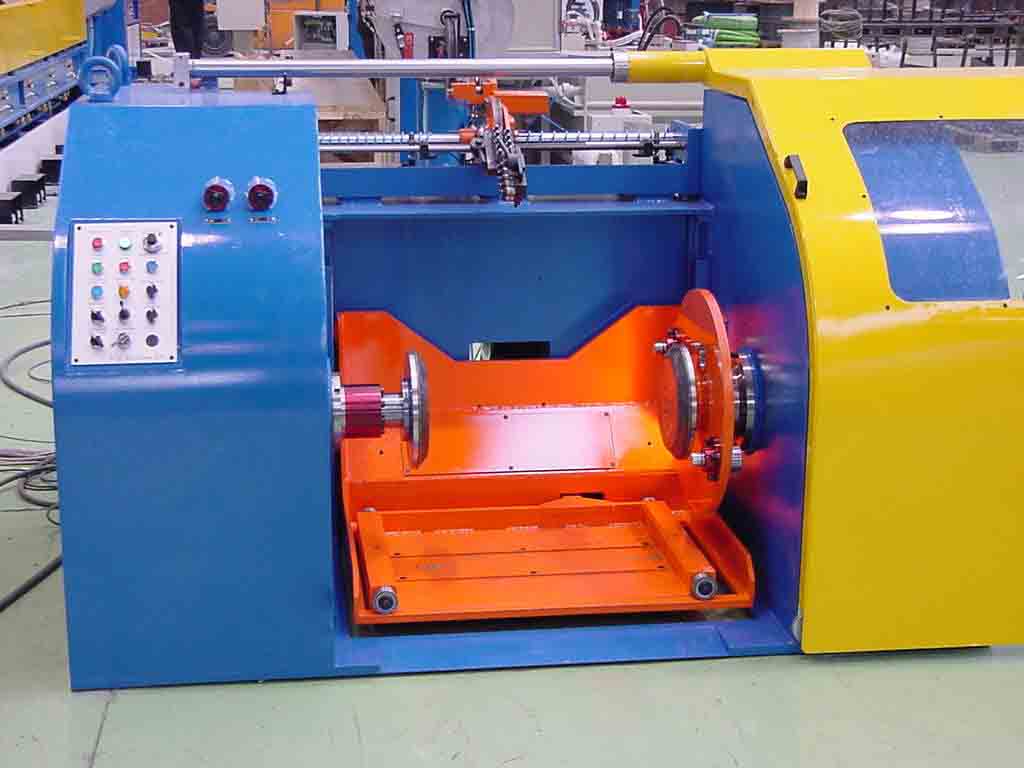

A HORIZONTAL Wire Spooling Machine is a piece of equipment that is used in various industries for winding and unwinding materials such as wire, cable, rope, and tubing. This machine offers several benefits that make it a valuable asset for businesses looking to improve their production processes.

One of the key benefits of using a horizontal spooling machine is its ability to increase efficiency. By automating the process of winding and unwinding materials, this machine can significantly reduce the amount of time and labor required to complete these tasks. This not only helps to improve productivity but also allows businesses to reallocate resources to other areas of their operations.

In addition to improving efficiency, a horizontal spooling machine can also help to enhance the quality of the finished product. By ensuring that materials are wound and unwound evenly and consistently, this machine can help to prevent issues such as tangling, twisting, and stretching. This can result in a higher-quality product that meets the standards of customers and reduces the likelihood of defects or rework.

Another benefit of using a horizontal spooling machine is its versatility. These machines can be customized to accommodate a wide range of materials and sizes, making them suitable for use in various industries. Whether you are working with thin wire or thick cable, a horizontal spooling machine can be tailored to meet your specific needs and requirements.

Furthermore, a horizontal spooling machine can help to improve workplace safety. By automating the process of winding and unwinding materials, this machine can reduce the risk of injuries and accidents that can occur when these tasks are performed manually. This can create a safer working environment for employees and help to minimize the potential for costly downtime due to workplace incidents.

Additionally, a horizontal Respooling Machine can help to reduce waste and save money. By ensuring that materials are wound and unwound efficiently, this machine can help to minimize the amount of scrap and rework that is generated during the production process. This can result in cost savings for businesses and help to improve their bottom line.

Overall, the benefits of using a horizontal spooling machine are clear. From improving efficiency and quality to enhancing workplace safety and reducing waste, this machine offers a range of advantages that can help businesses to streamline their operations and achieve their production goals. If you are looking to enhance your production processes and improve the quality of your products, investing in a horizontal spooling machine may be a wise decision.