Table of Contents

Advantages of Using Horizontal Spooling Machine in Industrial Applications

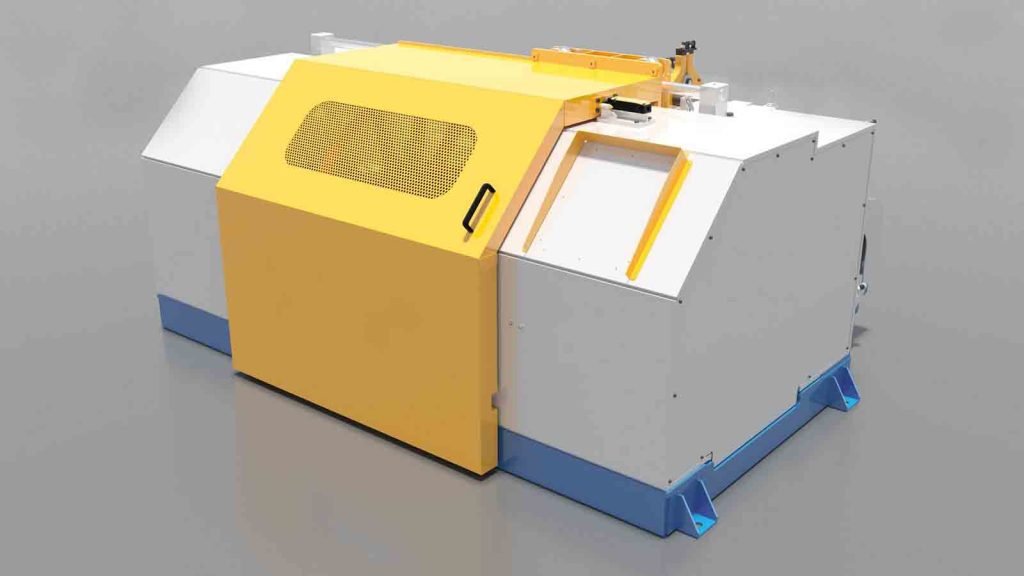

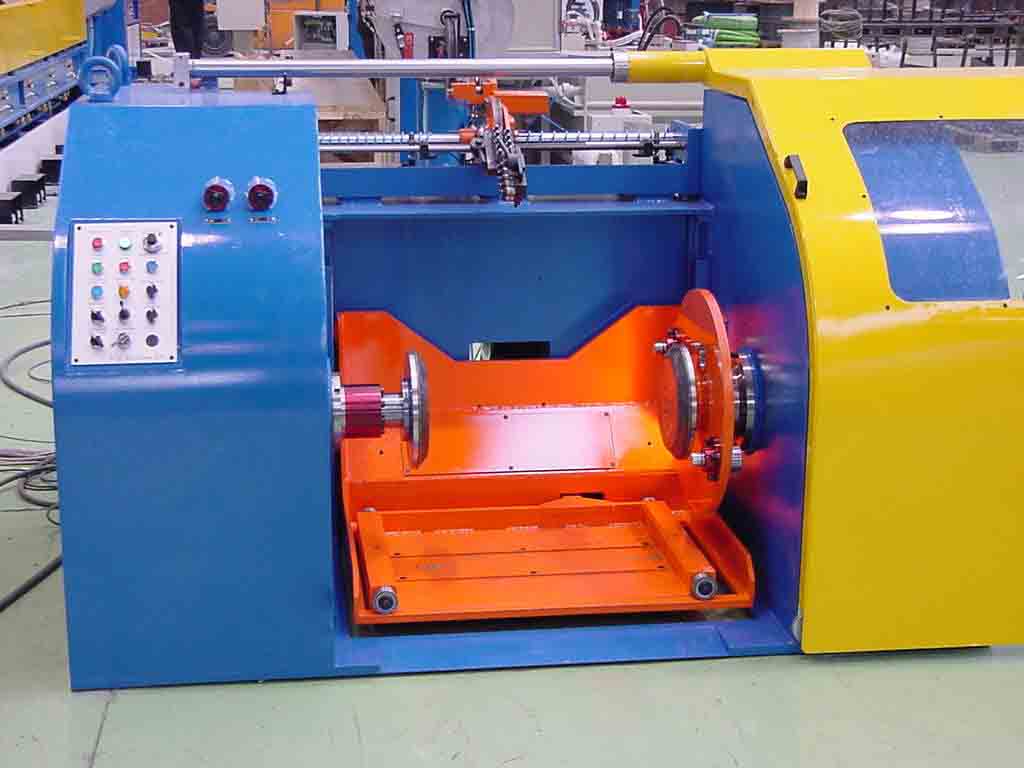

HORIZONTAL Wire Spooling Machine is an essential tool in various industrial applications, providing numerous advantages that make them a valuable asset for businesses. These machines are designed to wind materials such as wire, cable, rope, and tubing onto a spool in a horizontal orientation, offering several benefits over traditional vertical spooling machines.

One of the primary advantages of using a horizontal spooling machine is its space-saving design. Unlike vertical spooling machines that require a significant amount of vertical space, horizontal spooling machines can be easily integrated into existing production lines without taking up valuable floor space. This compact design allows businesses to maximize their workspace and increase efficiency in their operations.

In addition to their space-saving design, horizontal spooling machines offer increased flexibility in handling a wide range of materials. These machines can accommodate various spool sizes and types, making them suitable for different applications and industries. Whether you need to wind thin wire or thick cable, a horizontal spooling machine can be customized to meet your specific requirements.

Another advantage of using a horizontal spooling machine is its ease of operation. These machines are equipped with user-friendly controls and automation features that simplify the spooling process. Operators can easily adjust the speed, tension, and winding patterns to achieve the desired results quickly and efficiently. This ease of operation reduces the need for manual labor and minimizes the risk of errors, resulting in higher productivity and quality output.

Furthermore, horizontal spooling machines are known for their high-speed performance, allowing businesses to increase their production capacity and meet tight deadlines. These machines can wind materials at a faster rate than vertical spooling machines, enabling businesses to keep up with the demands of a fast-paced production environment. With their superior speed and efficiency, horizontal spooling machines help businesses streamline their operations and stay competitive in the market.

Additionally, horizontal spooling machines are designed for durability and reliability, ensuring long-term performance and minimal downtime. These machines are built with high-quality materials and components that can withstand the rigors of industrial use. With proper maintenance and care, a horizontal spooling machine can provide years of reliable service, making it a cost-effective investment for businesses.

In conclusion, horizontal spooling machines offer numerous advantages that make them an indispensable tool in industrial applications. From their space-saving design and flexibility to their ease of operation and high-speed performance, these machines provide businesses with the efficiency and productivity they need to succeed in today’s competitive market. With their durability and reliability, horizontal spooling machines are a valuable asset that can help businesses optimize their production processes and achieve their goals.

How to Properly Maintain and Troubleshoot Horizontal Spooling Machine in a Manufacturing Setting

Horizontal spooling machines are essential equipment in many manufacturing settings, used for winding materials such as wire, cable, rope, or tubing onto a spool or reel. Proper maintenance and troubleshooting of these machines are crucial to ensure smooth operation and prevent costly downtime. In this article, we will discuss some key tips on how to properly maintain and troubleshoot a horizontal spooling machine in a manufacturing setting.

Regular maintenance is essential to keep a horizontal Respooling Bobbin Machine running smoothly. One of the most important maintenance tasks is to regularly inspect and clean the machine. Dust, debris, and other contaminants can build up on the machine’s components, leading to malfunctions and decreased performance. Regular cleaning with a soft brush or cloth can help prevent these issues.

In addition to cleaning, it is important to regularly lubricate the moving parts of the machine. Proper lubrication can help reduce friction and wear, extending the life of the machine and ensuring smooth operation. Be sure to use the correct type of lubricant recommended by the manufacturer for each specific part of the machine.

Another important maintenance task is to regularly check the tension settings on the machine. Proper tension is crucial for achieving consistent winding results. If the tension is too high or too low, it can lead to uneven winding, snags, or other issues. Make sure to adjust the tension settings as needed to ensure optimal performance.

In addition to regular maintenance, it is important to troubleshoot any issues that may arise with the horizontal spooling machine. One common issue is uneven winding, which can be caused by a variety of factors such as improper tension settings, worn-out components, or misaligned spools. To troubleshoot this issue, start by checking the tension settings and adjusting them as needed. If the problem persists, inspect the machine for any worn or damaged parts that may need to be replaced.

Another common issue with horizontal spooling machines is jamming. Jamming can occur when the material being wound onto the spool gets stuck or tangled. To troubleshoot this issue, first, stop the machine and carefully remove any tangled material. Inspect the machine for any obstructions or misaligned components that may be causing the jamming. Once the issue is resolved, restart the machine and monitor it closely to ensure that the problem does not recur.

In conclusion, proper maintenance and troubleshooting are essential for ensuring the smooth operation of a horizontal spooling machine in a manufacturing setting. By regularly inspecting and cleaning the machine, lubricating moving parts, checking tension settings, and troubleshooting any issues that arise, you can help prevent costly downtime and ensure that the machine continues to perform at its best. Remember to follow the manufacturer’s guidelines for maintenance and troubleshooting to keep your horizontal spooling machine in top condition.