Table of Contents

Common Issues and Troubleshooting Tips for Aluminum Wire Breakdown Machine Drawing Machine

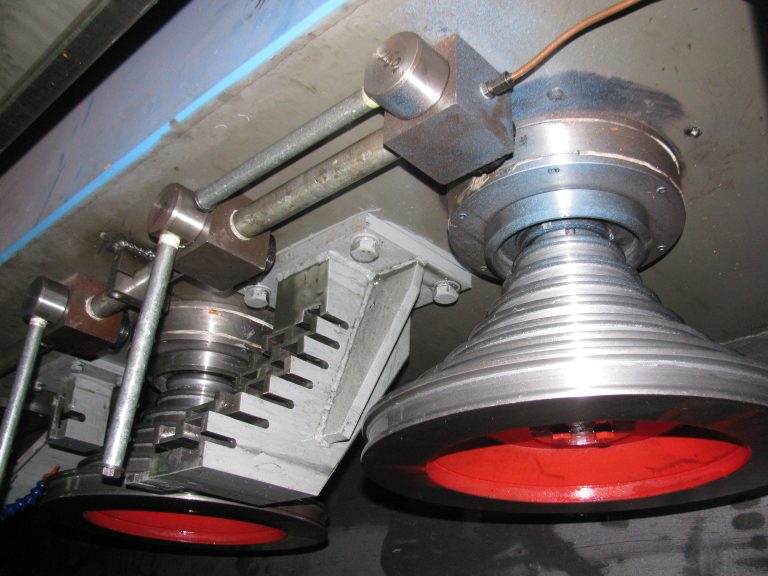

Aluminum wire breakdown machines are essential equipment in the wire drawing industry, used to reduce the diameter of aluminum wire by pulling it through a series of dies. However, like any machinery, breakdown machines can encounter issues that may affect their performance. In this article, we will discuss some common problems that may arise with aluminum wire breakdown machines and provide troubleshooting tips to help resolve them.

One common issue that operators may encounter with aluminum wire breakdown machines is wire breakage. This can occur due to a variety of reasons, such as improper tension settings, worn-out dies, or excessive speed. To troubleshoot this issue, operators should first check the tension settings on the machine and adjust them as needed to ensure that the wire is being pulled through the dies smoothly. Additionally, inspecting the dies for signs of wear and replacing them if necessary can help prevent wire breakage. Finally, reducing the speed of the machine can also help prevent breakage by allowing the wire to be drawn more slowly and evenly.

Another common issue with aluminum wire breakdown machines is uneven wire diameter. This can be caused by a misalignment of the dies, worn-out or damaged dies, or improper lubrication. To troubleshoot this issue, operators should first check the alignment of the dies and adjust them as needed to ensure that the wire is being drawn evenly. Inspecting the dies for signs of wear or damage and replacing them if necessary can also help improve the consistency of the wire diameter. Additionally, ensuring that the machine is properly lubricated can help reduce friction and improve the drawing process.

One more common issue that operators may face with aluminum wire breakdown machines is overheating. This can be caused by a variety of factors, such as excessive friction, inadequate cooling, or a malfunctioning motor. To troubleshoot this issue, operators should first check the cooling system on the machine and ensure that it is functioning properly. Additionally, reducing the speed of the machine can help reduce friction and prevent overheating. Inspecting the motor for signs of malfunction and addressing any issues can also help prevent overheating.

In conclusion, aluminum wire breakdown machines are essential equipment in the wire drawing industry, but they can encounter issues that may affect their performance. By understanding common problems such as wire breakage, uneven wire diameter, and overheating, operators can troubleshoot these issues and keep their machines running smoothly. By following the troubleshooting tips provided in this article, operators can address these issues effectively and ensure that their aluminum wire breakdown machines continue to operate efficiently.

How to Properly Maintain and Care for Aluminum Wire Breakdown Machine Drawing Machine

Aluminum wire breakdown machine drawing machines are essential equipment in the wire manufacturing industry. These machines are used to reduce the diameter of aluminum wire by pulling it through a series of dies. Proper maintenance and care of these machines are crucial to ensure their optimal performance and longevity.

One of the most important aspects of maintaining an aluminum wire breakdown machine drawing machine is regular cleaning. Dust, dirt, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. It is recommended to clean the machine after each use to prevent buildup and ensure smooth operation.

In addition to regular cleaning, it is essential to lubricate the machine’s moving parts to reduce friction and wear. Lubrication should be done according to the manufacturer’s recommendations using the appropriate type of lubricant. Over-lubrication can attract dust and debris, while under-lubrication can cause excessive wear on the machine’s components.

Inspecting the machine for signs of wear and damage is another crucial aspect of maintenance. Check for loose or damaged parts, worn-out dies, and any other issues that may affect the machine’s performance. Addressing these issues promptly can prevent further damage and costly repairs.

Regular calibration of the machine is also important to ensure accurate wire diameter reduction. Improper calibration can result in inconsistent wire thickness and quality issues. Follow the manufacturer’s guidelines for calibration and make adjustments as needed to maintain the machine’s accuracy.

Proper storage of the machine when not in use is essential to prevent damage and prolong its lifespan. Store the machine in a clean, dry, and well-ventilated area away from moisture and extreme temperatures. Cover the machine with a protective tarp or sheet to prevent dust and debris from accumulating on its components.

Training your staff on the proper operation and maintenance of the aluminum wire breakdown machine drawing machine is crucial to ensure its longevity and optimal performance. Provide comprehensive training on how to use the machine safely and effectively, as well as how to perform routine maintenance tasks. Encourage your staff to report any issues or concerns with the machine promptly.

In conclusion, proper maintenance and care of an aluminum wire breakdown machine drawing machine are essential to ensure its optimal performance and longevity. Regular cleaning, lubrication, inspection, calibration, and storage are key aspects of maintaining the machine. Training your staff on the proper operation and maintenance of the machine is also crucial. By following these guidelines, you can prolong the lifespan of your machine and ensure consistent, high-quality wire production.