Table of Contents

Benefits of Using a Mechanical Sanding Belt Descaling Machine

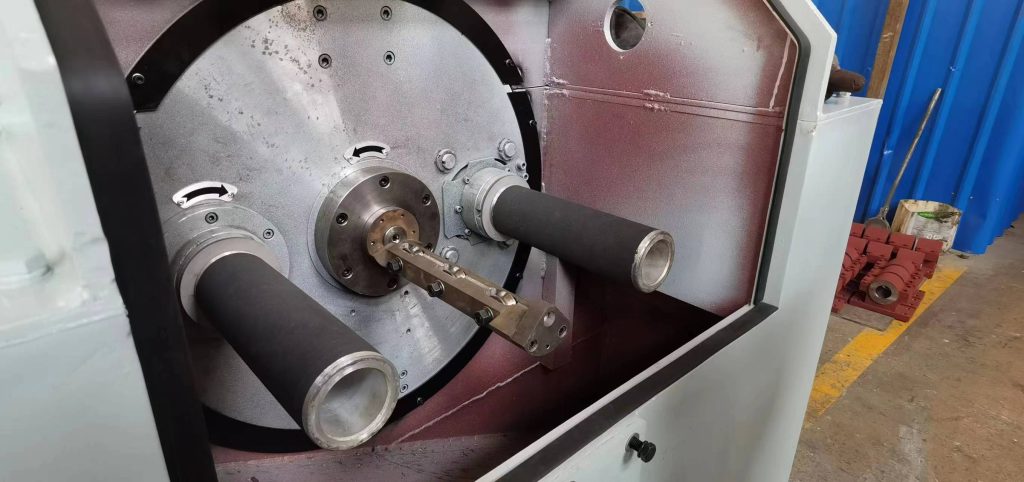

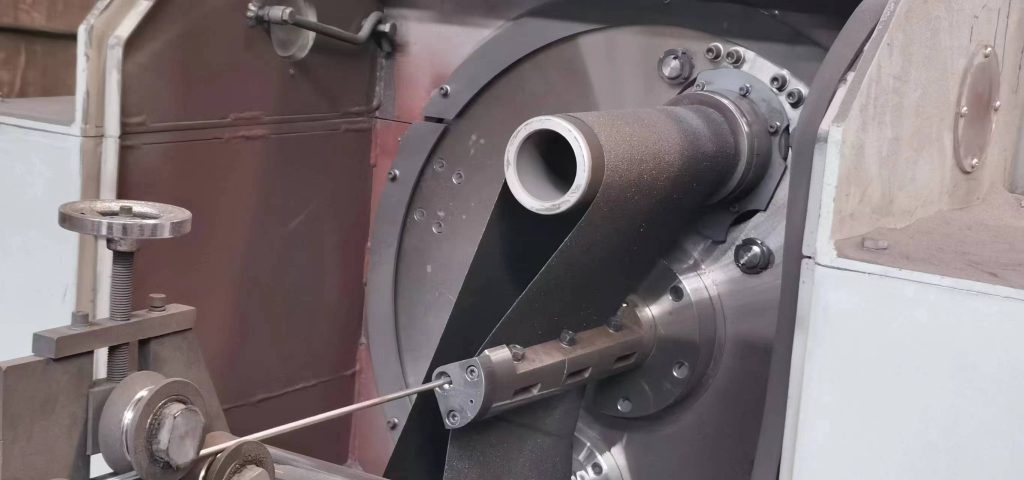

A Mechanical Descaling Sanding Belt Machine is a powerful tool that offers numerous benefits for various industries. This machine is designed to remove scale, rust, and other surface contaminants from metal surfaces quickly and efficiently. By using abrasive belts, the machine can achieve a smooth and clean finish on metal parts, making them ready for further processing or finishing.

One of the key benefits of using a mechanical sanding belt descaling machine is its ability to save time and labor. Manual descaling processes can be time-consuming and labor-intensive, requiring workers to spend hours sanding or grinding metal surfaces by hand. In contrast, a mechanical descaling machine can complete the same task in a fraction of the time, allowing workers to focus on other important tasks.

Additionally, a mechanical sanding belt descaling machine can improve the quality and consistency of the descaling process. Manual descaling methods can result in uneven finishes and inconsistent results, leading to rework and wasted materials. With a mechanical descaling machine, the abrasive belts provide a uniform finish across all metal surfaces, ensuring a high-quality result every time.

Furthermore, using a mechanical sand belt gringing machine can help reduce the risk of worker injuries and fatigue. Manual descaling processes can put a strain on workers’ muscles and joints, leading to potential injuries and long-term health issues. By automating the descaling process with a mechanical machine, workers can avoid repetitive strain injuries and work more efficiently without risking their health.

Another benefit of using a mechanical sanding belt descaling machine is its versatility and adaptability. These machines can be customized to meet the specific needs of different industries and applications, making them suitable for a wide range of descaling tasks. Whether descaling large metal sheets or small intricate parts, a mechanical descaling machine can be adjusted to deliver the desired finish with precision and accuracy.

In addition to saving time and labor, improving quality and consistency, and reducing the risk of worker injuries, a mechanical sanding belt descaling machine can also help increase productivity and profitability for businesses. By streamlining the descaling process and producing high-quality finishes, businesses can meet customer demands more efficiently and effectively, leading to increased customer satisfaction and repeat business.

Overall, the benefits of using a mechanical sanding belt descaling machine are clear. From saving time and labor to improving quality and consistency, reducing the risk of worker injuries, and increasing productivity and profitability, this machine offers numerous advantages for businesses in various industries. By investing in a mechanical descaling machine, businesses can enhance their descaling processes, achieve better results, and stay ahead of the competition in today’s fast-paced market.

How to Properly Maintain and Care for Your Mechanical Sanding Belt Descaling Machine

Mechanical sanding belt descaling machines are essential tools for removing rust, scale, and other surface contaminants from metal surfaces. These machines are commonly used in industries such as manufacturing, construction, and automotive to prepare metal surfaces for painting, welding, or other finishing processes. Proper maintenance and care of your mechanical sanding belt descaling machine are crucial to ensure its optimal performance and longevity.

One of the most important aspects of maintaining a mechanical sanding belt descaling machine is regular cleaning. After each use, it is essential to clean the machine thoroughly to remove any debris, dust, or metal particles that may have accumulated on the machine’s surface. This will help prevent the buildup of contaminants that can affect the machine’s performance and efficiency.

In addition to regular cleaning, it is also important to inspect the machine for any signs of wear or damage. Check the sanding belt for any tears, cuts, or signs of wear, and replace it if necessary. Inspect the machine’s motor, bearings, and other components for any signs of wear or damage, and make any necessary repairs or replacements to ensure the machine’s continued operation.

Proper lubrication is another key aspect of maintaining a mechanical sand belt gringing machine. Lubricate the machine’s moving parts, such as the bearings and motor, regularly to reduce friction and wear, and ensure smooth operation. Use the manufacturer’s recommended lubricants and follow the recommended maintenance schedule to keep the machine running smoothly.

Regularly inspect the machine’s electrical components, such as the power cord, switches, and controls, for any signs of wear or damage. Replace any damaged or worn components to prevent electrical hazards and ensure the machine’s safe operation. It is also important to follow the manufacturer’s recommended maintenance schedule for electrical components to prevent malfunctions and ensure the machine’s continued reliability.

Proper storage of your mechanical sanding belt descaling machine is also essential to maintain its performance and longevity. Store the machine in a clean, dry, and well-ventilated area to prevent rust, corrosion, or other damage. Cover the machine with a protective tarp or sheet to keep dust and debris out and protect it from the elements.

Regularly inspect the machine’s sanding belt tension and tracking to ensure proper alignment and tension. Adjust the tension and tracking as needed to prevent belt slippage, uneven wear, or other issues that can affect the machine’s performance. Follow the manufacturer’s recommended guidelines for adjusting the belt tension and tracking to ensure optimal performance.

In conclusion, proper maintenance and care of your mechanical sanding belt descaling machine are essential to ensure its optimal performance and longevity. Regular cleaning, inspection, lubrication, and storage are key aspects of maintaining the machine and preventing wear, damage, or malfunctions. By following these maintenance tips and guidelines, you can keep your mechanical sanding belt descaling machine in top condition and ensure its continued reliability and efficiency.