Table of Contents

Advantages of Using High Speed Dead Block Coiler in Wire and Cable Manufacturing

High Speed Dead Block Coilers have become an essential tool in the wire and cable manufacturing industry due to their numerous advantages. These coilers are designed to efficiently wind wire or cable onto a spool without the need for a rotating drum, making them ideal for high-speed production lines. In this article, we will explore the benefits of using a High Speed Dead Block Coiler in wire and cable manufacturing.

One of the main advantages of using a High Speed Dead Block Coiler is its ability to increase production efficiency. By eliminating the need for a rotating drum, these coilers can wind wire or cable at much higher speeds than traditional coilers. This results in faster production times and increased output, allowing manufacturers to meet tight deadlines and fulfill large orders more quickly.

Additionally, High Speed Dead Block Coilers are known for their precision winding capabilities. The design of these coilers ensures that the wire or cable is wound evenly and tightly onto the spool, reducing the risk of tangling or snags. This level of precision is crucial in the wire and cable industry, where quality control is paramount to ensuring the reliability and safety of the final product.

Another advantage of using a High Speed Dead Block Coiler is its versatility. These coilers can accommodate a wide range of wire and cable sizes, making them suitable for a variety of production needs. Whether manufacturers are working with thin, delicate wires or thick, heavy-duty cables, a High Speed Dead Block Coiler can handle the job with ease.

In addition to their efficiency, precision, and versatility, High Speed Dead Block Coilers also offer cost savings for manufacturers. By increasing production speeds and reducing the risk of errors or defects, these coilers help to minimize downtime and waste, ultimately leading to lower production costs. This cost-effectiveness makes High Speed Dead Block Coilers a smart investment for wire and cable manufacturers looking to improve their bottom line.

Furthermore, High Speed Dead Block Coilers are easy to operate and maintain, requiring minimal training for operators. This user-friendly design allows manufacturers to quickly integrate these coilers into their production lines without significant downtime or disruptions. Additionally, the durable construction of High Speed Dead Block Coilers ensures long-term reliability and performance, reducing the need for frequent repairs or replacements.

Overall, the advantages of using a High Speed Dead Block Coiler in wire and cable manufacturing are clear. From increased production efficiency and precision winding capabilities to versatility, cost savings, and ease of operation, these coilers offer numerous benefits for manufacturers looking to streamline their production processes and improve their bottom line. With their proven track record of success in the industry, High Speed Dead Block Coilers have become a staple tool for wire and cable manufacturers worldwide.

How to Optimize Production Efficiency with High Speed Dead Block Coiler Technology

In the world of manufacturing, efficiency is key. Companies are constantly looking for ways to optimize their production processes in order to increase output and reduce costs. One technology that has been gaining popularity in recent years is the high-speed Static Coiler With Horizontal Capstan. This innovative piece of equipment is designed to streamline the coiling process, allowing for faster production speeds and improved overall efficiency.

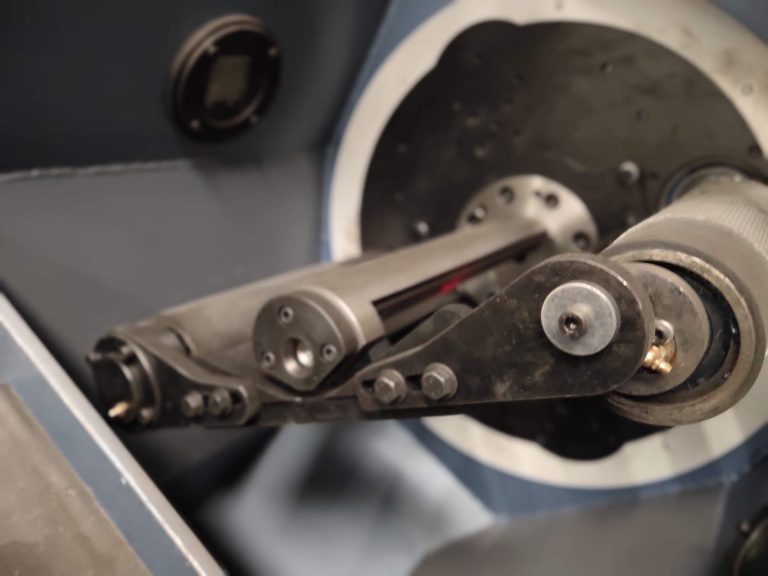

The high-speed dead block coiler works by automatically coiling wire or cable onto a spool or reel. This eliminates the need for manual coiling, which can be time-consuming and labor-intensive. By automating this process, companies can significantly increase their production output without having to hire additional workers.

One of the key benefits of the high-speed dead block coiler is its ability to coil wire or cable at incredibly fast speeds. This allows companies to meet tight production deadlines and fulfill customer orders in a timely manner. In addition, the high-speed coiling process results in a more uniform and consistent coil, which can improve the overall quality of the finished product.

Another advantage of the high-speed dead block coiler is its versatility. This technology can be used to coil a wide range of wire and cable sizes, making it suitable for a variety of industries. Whether you are producing electrical wiring, telecommunications cables, or industrial hoses, the high-speed dead block coiler can help you optimize your production process.

In addition to increasing production speeds, the high-speed dead block coiler can also help companies reduce waste and improve overall efficiency. By automating the coiling process, companies can minimize the risk of human error and ensure that each coil is produced to the highest standards. This can result in fewer defects and less scrap material, ultimately saving companies time and money.

Furthermore, the high-speed dead block coiler is designed to be easy to operate and maintain. With user-friendly controls and minimal moving parts, this technology is simple to set up and use. Additionally, the high-speed coiler requires less maintenance than traditional coiling equipment, reducing downtime and increasing overall productivity.

Overall, the high-speed dead block coiler is a valuable tool for companies looking to optimize their production efficiency. By automating the coiling process, this technology can help companies increase production speeds, improve product quality, and reduce waste. With its versatility and ease of use, the high-speed dead block coiler is a smart investment for any manufacturing operation looking to stay ahead of the competition.