Table of Contents

Exploring the Benefits of Investing in an Automatic Straightening and Cutting Machine for Your Business

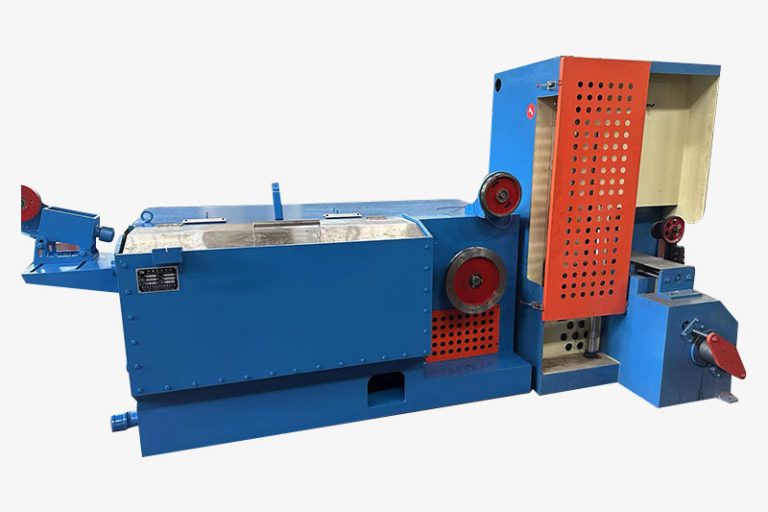

Investing in an Automatic Wire Straightening And Cutting Machines can greatly benefit your business in a number of ways. These machines are designed to streamline the process of straightening and cutting metal rods, wires, and tubes, making them an essential tool for businesses in industries such as construction, manufacturing, and automotive. In this article, we will explore the various benefits of investing in an automatic straightening and cutting machine for your business.

One of the primary benefits of using an automatic straightening and cutting machine is the increase in efficiency and productivity that it provides. These machines are capable of straightening and cutting metal materials at a much faster rate than manual methods, allowing your business to complete projects more quickly and meet tight deadlines. This increased efficiency can also lead to cost savings, as less time and labor are required to complete each task.

In addition to improving efficiency, automatic straightening and cutting machines also offer greater precision and accuracy in the cutting process. These machines are equipped with advanced technology that allows them to make precise cuts with minimal error, ensuring that each piece is cut to the exact specifications required. This level of precision is essential for businesses that require consistent and accurate cuts in their metal materials.

Another benefit of investing in a Wire Cutting Machines in Welding Electrode Plants is the reduction in waste that it provides. Manual cutting methods can often result in a significant amount of material waste, as human error can lead to incorrect cuts or uneven lengths. Automatic machines, on the other hand, are programmed to make precise cuts every time, minimizing waste and maximizing the use of materials. This can lead to cost savings for your business in the long run.

Furthermore, automatic straightening and cutting machines are designed to improve worker safety in the workplace. Manual cutting methods can be dangerous, as they require workers to handle sharp tools and heavy materials. Automatic machines eliminate the need for manual cutting, reducing the risk of accidents and injuries in the workplace. This can help to create a safer and more efficient working environment for your employees.

In conclusion, investing in an automatic straightening and cutting machine can provide numerous benefits for your business. From increased efficiency and productivity to greater precision and accuracy in cutting, these machines offer a wide range of advantages that can help your business succeed. Additionally, the reduction in waste and improvement in worker safety that these machines provide make them a valuable investment for businesses in a variety of industries. If you are looking to improve your cutting processes and streamline your operations, consider investing in an automatic straightening and cutting machine for your business.

How to Choose the Right Automatic Straightening and Cutting Machine for Your Specific Needs

Automatic wire straightening and cutting machines are essential tools in various industries, such as construction, manufacturing, and metalworking. These machines are designed to straighten and cut metal wires, rods, and tubes with precision and efficiency. If you are in the market for an automatic straightening and cutting machine, it is important to choose the right one for your specific needs. In this article, we will discuss some key factors to consider when selecting an automatic straightening and cutting machine for sale.

One of the first things to consider when choosing an automatic straightening and cutting machine is the type of material you will be working with. Different machines are designed to handle different types of materials, such as steel, aluminum, copper, or titanium. Make sure to choose a machine that is compatible with the material you will be using to ensure optimal performance and efficiency.

Another important factor to consider is the size and thickness of the material you will be working with. Automatic straightening and cutting machines come in a variety of sizes and configurations, so it is important to choose a machine that can accommodate the size and thickness of the material you will be processing. Consider the maximum diameter and length of the material that the machine can handle to ensure that it meets your specific requirements.

In addition to material type and size, it is also important to consider the production capacity of the automatic straightening and cutting machine. Production capacity refers to the amount of material that the machine can process in a given amount of time. If you have high-volume production requirements, you will need a machine with a higher production capacity to meet your needs. Consider factors such as cutting speed, feed rate, and cycle time when evaluating the production capacity of a machine.

When choosing an automatic straightening and cutting machine, it is also important to consider the level of automation and control features that are available. Some machines come with advanced automation features, such as programmable controls, touch screen interfaces, and remote monitoring capabilities. These features can help improve efficiency, accuracy, and productivity in your operations. Consider your specific requirements and preferences when evaluating the automation and control features of a machine.

Another important factor to consider when choosing an automatic straightening and cutting machine is the overall quality and reliability of the machine. Look for machines that are built with high-quality materials and components to ensure durability and longevity. Consider factors such as brand reputation, warranty coverage, and customer reviews when evaluating the quality and reliability of a machine.

In conclusion, choosing the right automatic straightening and cutting machine for your specific needs requires careful consideration of factors such as material type, size, production capacity, automation features, and quality. By taking the time to evaluate these factors and compare different machines, you can select a machine that meets your requirements and helps improve the efficiency and productivity of your operations. Whether you are in the construction, manufacturing, or metalworking industry, investing in a high-quality automatic straightening and cutting machine can help you achieve your production goals and deliver high-quality products to your customers.