Table of Contents

How to Properly Maintain and Troubleshoot Horizontal Wire Spooler Machine

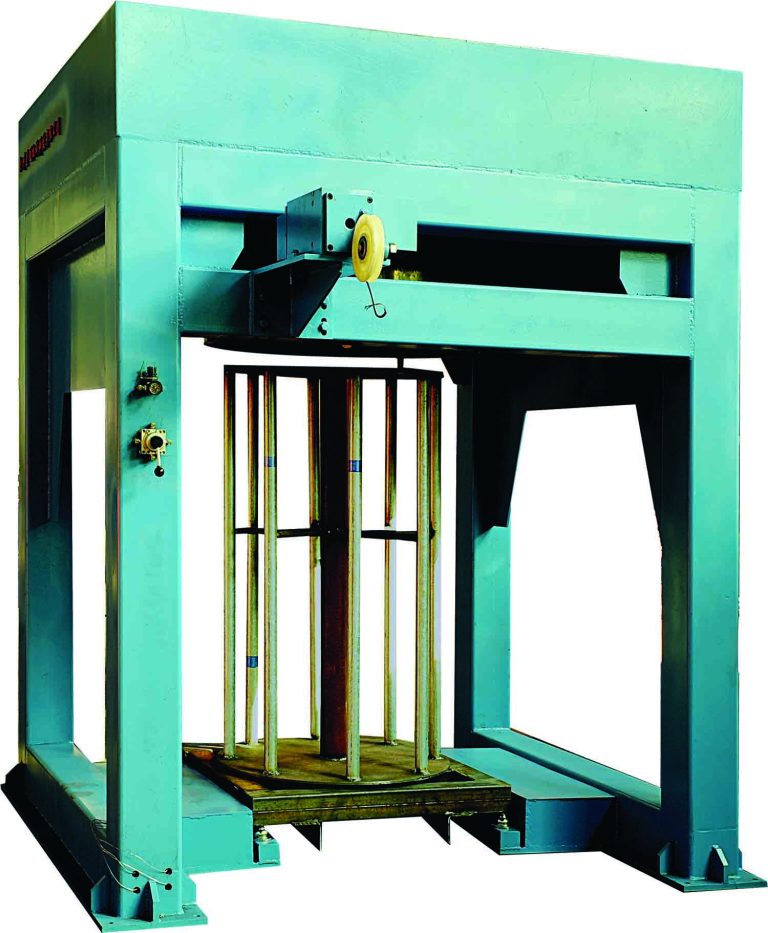

HORIZONTAL Wire Spooling Machine is essential equipment in various industries that deal with wire processing and manufacturing. These machines are designed to wind wire onto spools in a horizontal orientation, making the process more efficient and streamlined. Proper maintenance and troubleshooting of these machines are crucial to ensure smooth operation and prevent costly downtime.

To properly maintain a horizontal wire spooler machine, regular inspection and cleaning are key. Inspect the machine for any signs of wear and tear, such as loose or damaged parts, and replace them as needed. Clean the machine regularly to remove any dirt, debris, or wire residue that may accumulate and cause malfunctions. Lubricate moving parts to reduce friction and ensure smooth operation.

In addition to regular maintenance, it is important to follow the manufacturer’s guidelines for operating the machine. This includes using the correct wire spool size and type, as well as setting the machine to the appropriate speed and tension levels. Improper settings can lead to wire breakage, spooling errors, and other issues that can affect the quality of the finished product.

When troubleshooting a horizontal wire spooler machine, start by identifying the problem and its possible causes. Common issues include wire tangling, spooling unevenness, and motor malfunctions. Check the wire path for any obstructions or misalignments that may be causing the problem. Adjust the tension and speed settings to see if that resolves the issue.

If the problem persists, consult the machine’s manual or contact the manufacturer for further assistance. They may be able to provide troubleshooting tips or recommend a professional technician to inspect and repair the machine. It is important not to attempt any repairs or modifications without proper training and knowledge, as this can lead to further damage and safety hazards.

In some cases, preventive maintenance measures can help prevent issues before they occur. This includes regularly checking and replacing worn parts, cleaning and lubricating the machine, and conducting routine inspections to identify potential problems early on. By staying proactive and attentive to the machine’s condition, you can minimize downtime and ensure consistent performance.

Overall, proper maintenance and troubleshooting of a horizontal wire spooler machine are essential for its longevity and efficiency. By following the manufacturer’s guidelines, conducting regular inspections, and addressing issues promptly, you can keep the machine running smoothly and avoid costly repairs. Remember to prioritize safety and consult professionals when needed to ensure the machine operates at its best. With proper care and attention, your horizontal wire spooler machine can continue to meet your production needs effectively.

Benefits of Using Horizontal Wire Spooler Machine in Industrial Applications

In industrial applications where wire spooling is a common task, the use of a horizontal wire spooler machine can offer numerous benefits. This specialized piece of equipment is designed to efficiently wind wire onto spools in a horizontal orientation, making it ideal for a wide range of industries such as telecommunications, construction, and manufacturing.

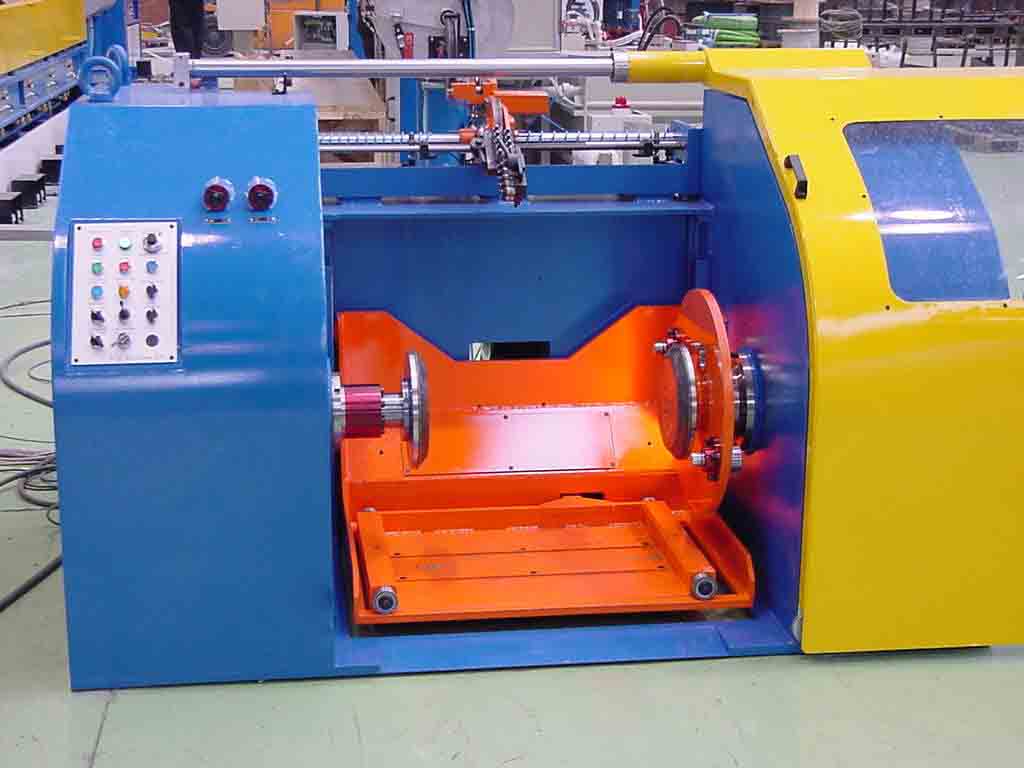

One of the key advantages of using a horizontal wire Respooling Machine is its ability to increase productivity. By automating the spooling process, workers can save time and effort that would otherwise be spent manually winding wire onto spools. This can result in faster production times and higher output levels, ultimately leading to cost savings for the company.

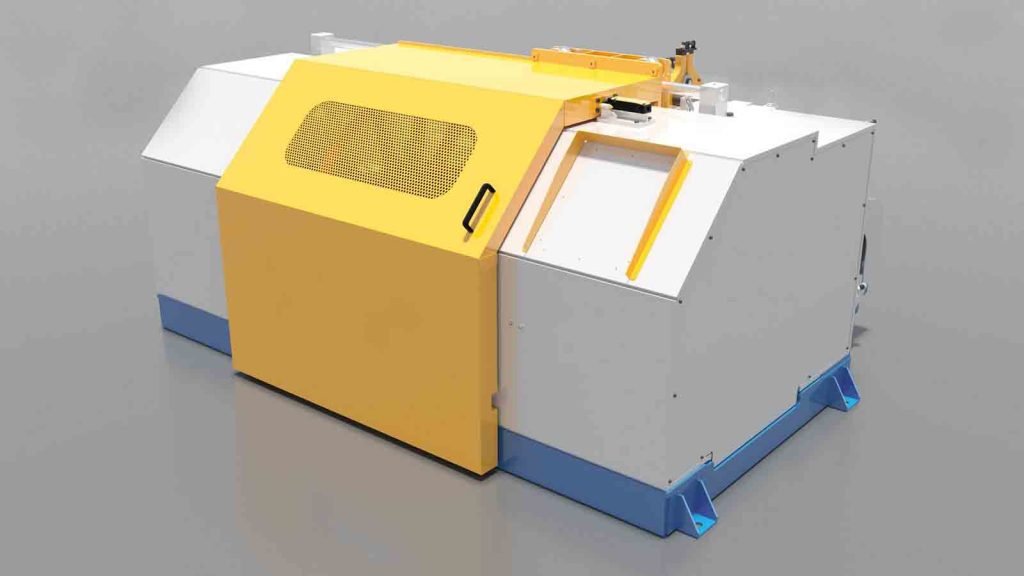

Additionally, horizontal wire spooler machines are designed to handle a wide range of wire sizes and types, making them versatile tools for various applications. Whether you are working with thin gauge wire for telecommunications or heavy-duty wire for construction projects, a horizontal wire spooler machine can accommodate your needs. This flexibility allows for greater efficiency and adaptability in the workplace.

Another benefit of using a horizontal wire spooler machine is the improved safety it provides for workers. Manual wire spooling can be a hazardous task, as workers are often required to handle sharp wire ends and heavy spools. By using a horizontal wire spooler machine, these risks are minimized, as the machine handles the wire spooling process with precision and care. This can help reduce the likelihood of workplace accidents and injuries, creating a safer working environment for all employees.

Furthermore, horizontal wire spooler machines are designed to be user-friendly and easy to operate. With intuitive controls and simple setup procedures, workers can quickly learn how to use the machine effectively, reducing the need for extensive training or specialized skills. This can help streamline operations and improve overall efficiency in the workplace.

In addition to these benefits, horizontal wire spooler machines are also known for their durability and reliability. Built to withstand the rigors of industrial use, these machines are constructed from high-quality materials that can withstand heavy-duty applications. This ensures that the machine will continue to perform consistently over time, providing a long-lasting solution for wire spooling needs.

Overall, the use of a horizontal wire spooler machine in industrial applications can offer a wide range of benefits, including increased productivity, versatility, safety, ease of use, and durability. By investing in this specialized equipment, companies can improve their operations and achieve greater efficiency in wire spooling tasks. Whether you are looking to streamline production processes, enhance workplace safety, or increase output levels, a horizontal wire spooler machine can be a valuable asset for your business.