One of the main benefits of using a Steel Brush Descaler for Wire Drawing Process is the increase in productivity that it provides. These machines are able to clean metal surfaces much faster than manual methods, allowing workers to complete their tasks more quickly and move on to other projects. This can help to increase overall efficiency in the workplace and reduce downtime caused by cleaning and maintenance tasks.

In addition to increased productivity, using a Brush machine for wire drawing machine can also improve safety in the workplace. Manual cleaning methods, such as using hand tools or chemicals, can be dangerous and expose workers to harmful fumes and substances. By using a machine to clean metal surfaces, workers can avoid these risks and ensure that they are working in a safe environment.

Another benefit of using a brush descaler machine is the cost savings that it provides. While these machines can be expensive to purchase initially, they can save money in the long run by reducing the need for manual labor and expensive cleaning chemicals. Additionally, using a machine to clean metal surfaces can help to extend the life of the equipment and prevent costly repairs and replacements.

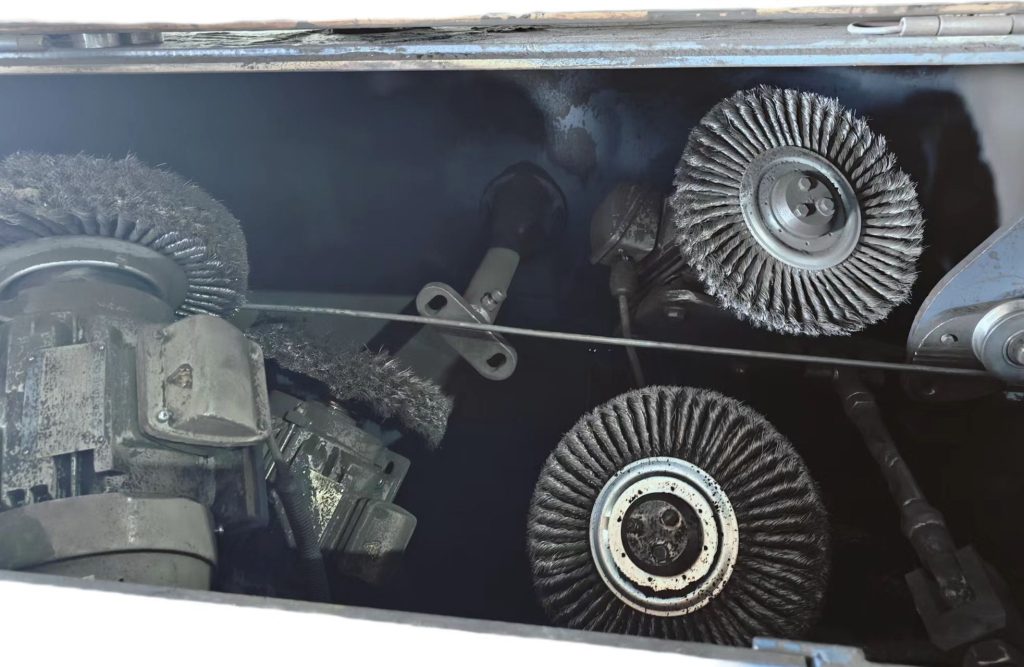

Wire brush descalers are also versatile tools that can be used on a wide range of metal surfaces. Whether you are cleaning pipes, tanks, or machinery, a Mechanical Descaling by Brushing can help to remove rust, scale, and other debris quickly and efficiently. This versatility makes these machines a valuable asset in any industrial setting.

Overall, using a Mechanical Wire Descaler with Wire Brushing Unit can provide a wide range of benefits for businesses and workers alike. From increased productivity and improved safety to cost savings and versatility, these machines offer a powerful solution for cleaning metal surfaces in industrial settings. By investing in a Wire Brush Descaler Machine, businesses can improve efficiency, reduce risks, and save money in the long run.