Table of Contents

IiNzuzo zokuSebenzisa uMtshini woNxibelelwano kwiMisebenzi yoShishino

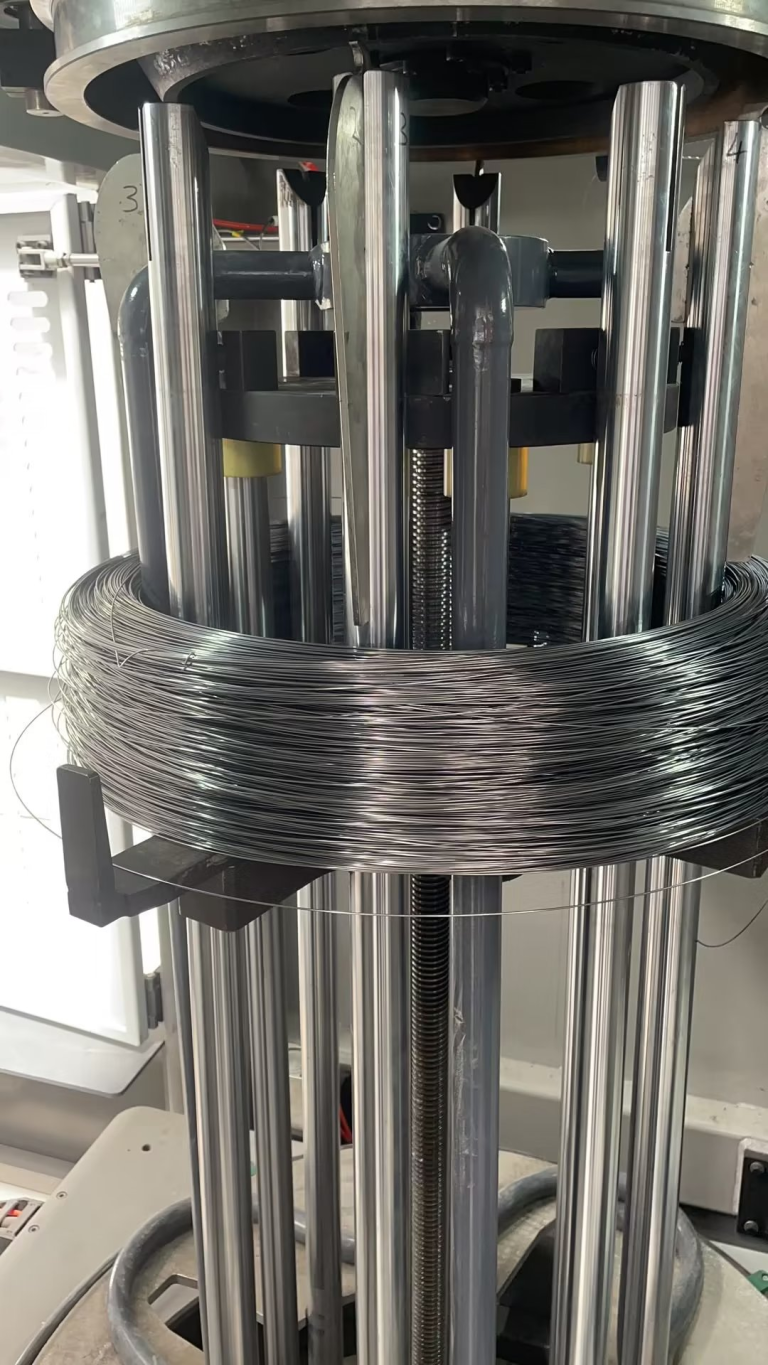

Indlela yokuGcina ngokuchanekileyo kunye nokuQothulwa kweNgxaki kuMatshini wokuSpoola ngocingo

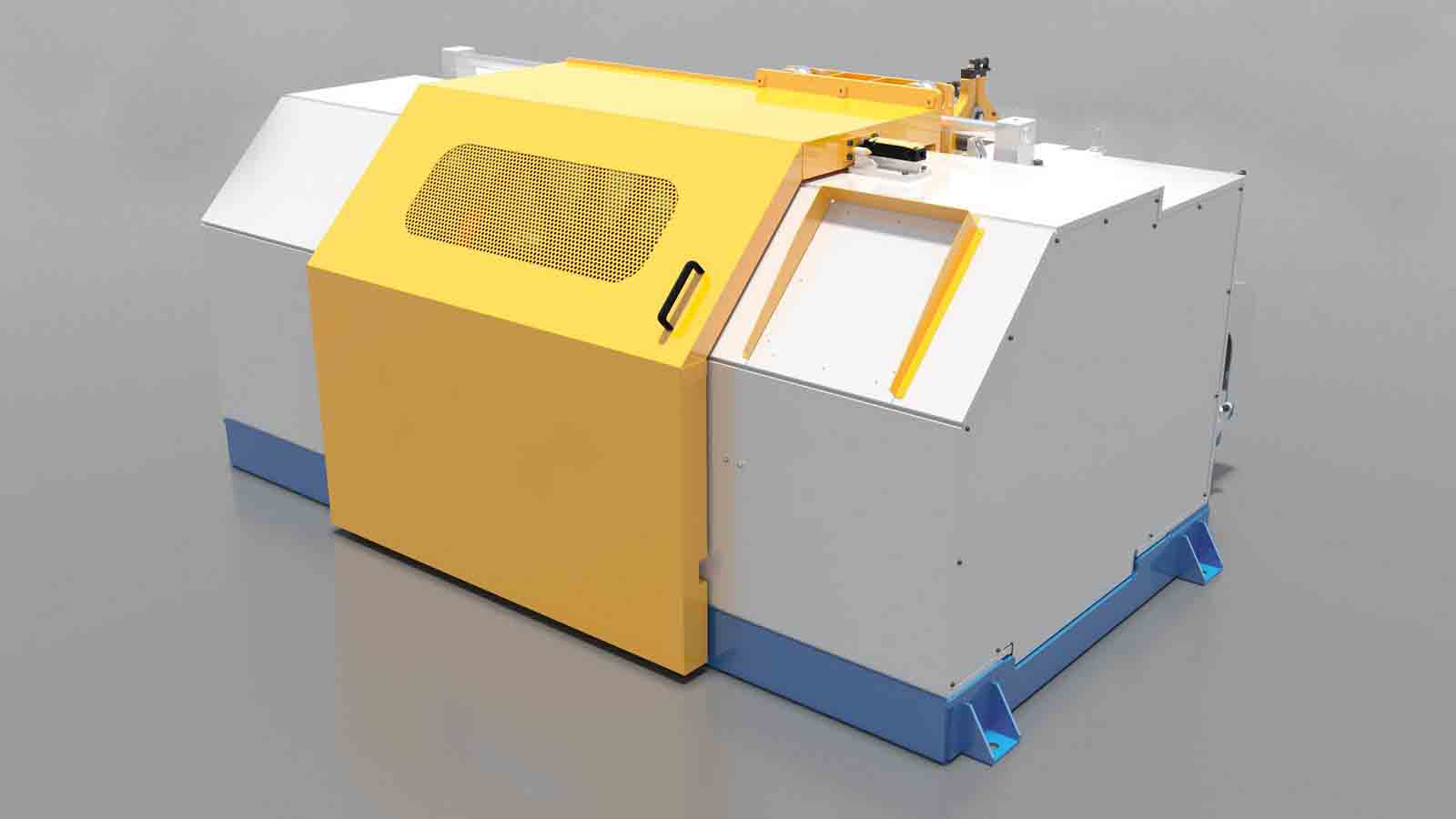

Oomatshini bokucoca ngocingo zizixhobo ezibalulekileyo kumashishini ahlukeneyo asebenza ngeengcingo kunye neentambo. Aba matshini basetyenziselwa ukuvuthela ucingo kwi-spool okanye i-reel, ukwenza kube lula ukuthutha kunye nokugcina. Ukugcinwa ngokufanelekileyo kunye nokusombulula ingxaki kumatshini wokucoca ucingo kubalulekile ukuqinisekisa ukusebenza kwawo ngokugqibeleleyo kunye nokuphila ixesha elide.

Enye yezona zinto zibalulekileyo zokugcina umatshini wokucoca ucingo kukucoca rhoqo. Uthuli, ubumdaka, nobutyobo bunokuqokelelana kumalungu omatshini, nto leyo ekhokelela kukungasebenzi kakuhle nokuncipha kokusebenza kakuhle. Kunconywa ukucoca umatshini emva kokusetyenziswa ngakunye ukukhusela ukwakhiwa kunye nokuqinisekisa ukusebenza kakuhle.

Ngaphezu kokucoca, ukuthambisa iindawo ezihambayo zomatshini wokucoca ucingo kubalulekile. Ukuthambisa kunceda ukunciphisa ingxabano phakathi kwamalungu, ukuthintela ukuguga kunye nokukrazula kunye nokwandisa ubomi bomatshini. Kubalulekile ukusebenzisa isithambisi esifanelekileyo kwindawo nganye yomatshini ukunqanda umonakalo.

Ukuhlolwa rhoqo komatshini wokucoca ucingo nako kuyimfuneko ukuchonga nayiphi na imiba enokubakho phambi kokuba inyuke. Khangela iindawo ezikhululekileyo okanye ezonakeleyo, izinto ezigugileyo, kunye neempawu zokubola. Ukujongana nale miba ngokukhawuleza kunokuthintela ukulungiswa okuxabisa imali eninzi kunye nexesha lokungasebenzi. Ukulungelelaniswa kuqinisekisa ukuba umatshini usebenza ngesantya esichanekileyo kunye noxinzelelo, okubangela ukuguquguquka kwecingo okuhambelanayo kunye nokuchanekileyo. Landela izikhokelo zomenzi wolungelelwaniso ukuqinisekisa ukusebenza ngokupheleleyo.

Xa ulungisa ingxaki kumatshini wokucoca ucingo, qalisa ngokuchonga ingxaki. Imiba eqhelekileyo ibandakanya ucingo oluxineneyo, ukujikajika okungalinganiyo, kunye nokungasebenzi kakuhle kwemoto. Nje ukuba ingxaki ichongiwe, jonga kwincwadana yemigaqo yomatshini yamanyathelo okusombulula ingxaki.

Ukuba umatshini wokucoca ucingo uxinene, susa ngononophelo ucingo oluphothiweyo kwaye uhlolisise amacandelo awo nawuphi na umonakalo. Khangela nayiphi na imiqobo kwindlela yocingo kwaye uqinisekise ukuba ukutsalwa kumiswe ngokuchanekileyo. Qalisa kwakhona umatshini kwaye ubeke iliso ekusebenzeni kwawo ukuqinisekisa ukuba umba usonjululwe.

Ukujika okungalungelelaniyo kunokubangelwa yimimiselo yoxinzelelo engafanelekanga okanye izinto ezingalungelelanisiweyo. Lungisa useto loxinzelelo ngokweenkcukacha zocingo kwaye uhlengahlengise naziphi na iindawo ezingalungelelananga kakuhle. Vavanya umatshini ngocingo oluncinane ukuqinisekisa ukuba ukujikajika kulungile kwaye akuguquguquki.

Ukuba injini ayisebenzi kakuhle, jonga umthombo wamandla kunye noqhagamshelo ukuqinisekisa ukuba zikhuselekile. Hlola i-motor naziphi na iimpawu zomonakalo okanye ukufudumeza. Ukuba i-motor idinga ukutshintshwa, qhagamshelana nomenzi wenxalenye yokutshintshwa kwaye ulandele imiyalelo yabo yokufakela.

Ekuqukumbeleni, ukugcinwa okufanelekileyo kunye nokusombulula ingxaki kumatshini wokucoca ucingo kubalulekile ukuqinisekisa ukusebenza kwawo ngokugqibeleleyo kunye nokuphila ixesha elide. Ukucoca rhoqo, ukuthambisa, ukuhlolwa, kunye nokulinganisa imiba ephambili yolondolozo. Xa ulungisa imiba, chonga ingxaki, jonga kwincwadana yezikhokelo, kwaye ulungise lo mba ngokukhawuleza. Ngokulandela ezi zikhokelo, unokugcina umatshini wakho wokucoca ucingo ukwimeko ephezulu kwaye uphephe ukulungiswa okuxabisa kakhulu kunye nexesha lokuphumla.

If the Wire Spooling Machine is jammed, carefully remove the tangled wire and inspect the components for any damage. Check for any obstructions in the wire path and ensure that the tension is set correctly. Restart the machine and monitor its operation to ensure the issue has been resolved.

Uneven winding can be caused by improper tension settings or misaligned components. Adjust the tension settings according to the wire specifications and realign any misaligned parts. Test the machine with a small amount of wire to ensure that the winding is even and consistent.

If the motor is malfunctioning, check the power source and connections to ensure they are secure. Inspect the motor for any signs of damage or overheating. If the motor needs to be replaced, contact the manufacturer for a replacement part and follow their instructions for installation.

In conclusion, proper maintenance and troubleshooting of a wire spooling machine are essential to ensure its optimal performance and longevity. Regular cleaning, lubrication, inspection, and calibration are key aspects of maintenance. When troubleshooting issues, identify the problem, refer to the manual for guidance, and address the issue promptly. By following these guidelines, you can keep your wire spooling machine in top condition and avoid costly repairs and downtime.