Table of Contents

IiNzuzo zokuSebenzisa umatshini wokuzoba ngocingo olumanzi kwiAluminiyam yocingo

Indlela yokukhetha uMshini oLungileyo woMzobo weeNcingo zoMbane kwiAluminiyam yakho yoMveliso weNtambo yokuVelisa

Xa ujonge ukuthenga umatshini wokudweba ucingo olumanzi kumgca wakho wokuvelisa ucingo lwe-aluminium, kukho izinto ezininzi zokuqwalasela ukuqinisekisa ukuba ukhetha okulungileyo kwiimfuno zakho ezithile. Enye yezinto zokuqala ekufuneka ziqwalaselwe bubukhulu kunye nomthamo womatshini. Kuya kufuneka uqikelele ubungakanani bedayamitha yocingo oza kuluzoba, kunye nedayamitha yokugqibela oyifunayo. Oku kuya kukunceda ukhethe umatshini onokuphatha ubungakanani kunye nomthamo wocingo oza kusebenza ngalo.

Enye into ebalulekileyo ekufuneka uyiqwalasele sisantya kunye nokusebenza kakuhle komatshini. Umatshini okhawulezayo uya kukwazi ukuvelisa ucingo oluninzi ngexesha elincinci, ukwandisa imveliso yakho yonke. Khangela umatshini onika ulawulo lwesantya esiguquguqukayo, ngoko unokulungelelanisa isantya ukuhlangabezana neemfuno zakho zokuvelisa.

Ngaphezu kobukhulu kunye nesantya, kubalulekile ukuqwalasela umgangatho kunye nokuqina komatshini. Khangela umatshini owenziwe kwizinto ezikumgangatho ophezulu kwaye unokwakhiwa okuqinileyo. Oku kuya kuqinisekisa ukuba umatshini unokumelana nobunzima bokusetyenziswa kwansuku zonke kwaye unikeze ukusebenza okuthembekileyo kwiminyaka ezayo.

Xa uthengela umatshini wokudweba ucingo olumanzi, kubalulekile ukuqwalasela inqanaba lezinto ezizenzekelayo kunye nokulawula iimpawu. Abanye oomatshini banikezela ngeempawu ezizenzekelayo ezizenzekelayo, ezifana nolawulo lwedijithali kunye neenkqubo zokubeka iliso, ezinokunceda ukuphucula ukusebenza kakuhle kunye nokunciphisa umngcipheko weempazamo. Khangela umatshini onikezela ngenqanaba lokuzenzekelayo olulungele iimfuno zakho zokuvelisa.

Ekugqibeleni, qwalasela udumo kunye nokuthembeka komenzi. Khangela inkampani enerekhodi eqinisekisiweyo yokuvelisa oomatshini bokuzoba ngocingo olukumgangatho ophezulu kunye nokubonelela ngenkonzo ebalaseleyo yabathengi. Ukufunda uphononongo kunye nobungqina obuvela kwabanye abathengi kunokukunceda ukulinganisa igama lomenzi kwaye wenze isigqibo esinolwazi.

Ekuqukumbeleni, ukukhetha umatshini ochanekileyo wokudweba ucingo olumanzi kumgca wakho wokuvelisa ucingo lwe-aluminium kubalulekile ekufezekiseni iziphumo eziphezulu kunye nokwandisa. imveliso. Cinga izinto ezinje ngobungakanani, isantya, umgangatho, i-automation, kunye nodumo lomenzi xa usenza isigqibo. Ngokuthatha ixesha lokuphanda kunye nokuvavanya ukhetho lwakho, unokufumana umatshini ohlangabezana neemfuno zakho ezithile kwaye uncede ufezekise impumelelo kwimisebenzi yakho yokuvelisa ucingo.

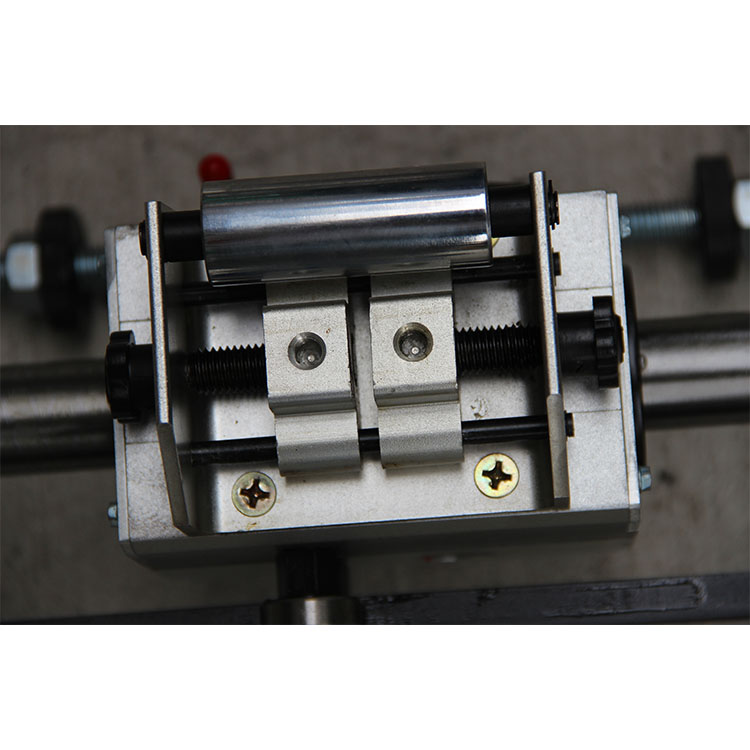

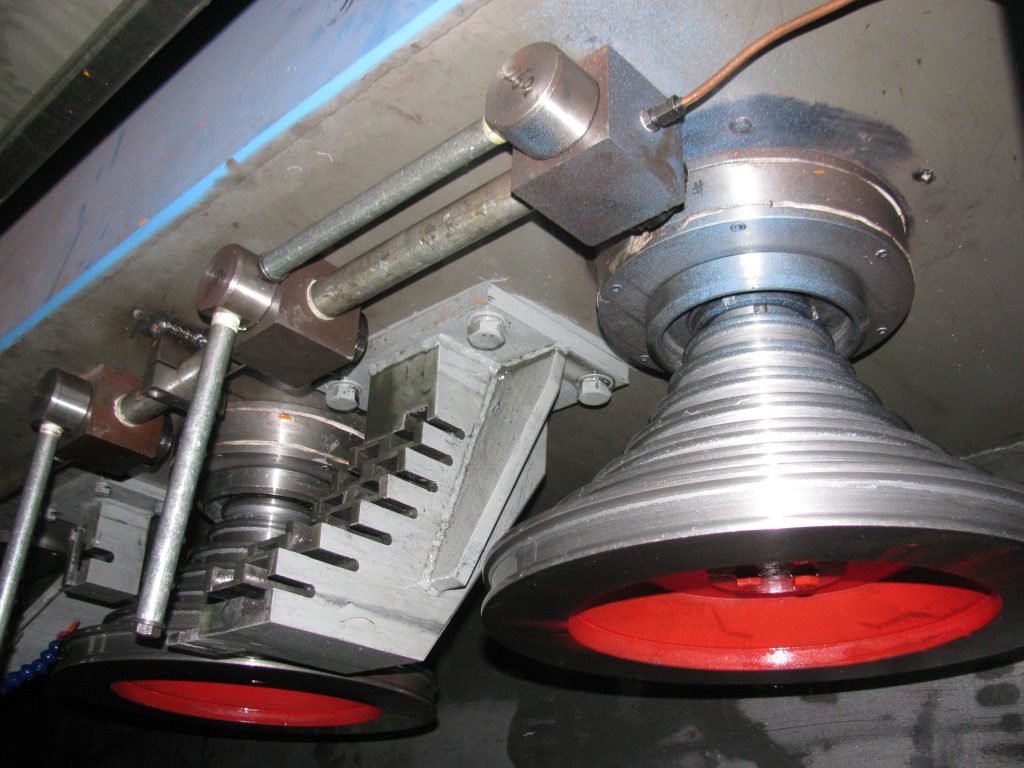

When it comes to producing high-quality aluminium wire, having the right equipment is essential. One key piece of machinery that is crucial for the production process is a wet wire drawing machine. This machine is used to reduce the diameter of the wire by pulling it through a series of dies, resulting in a smoother surface finish and improved mechanical properties.

When looking to purchase a wet wire drawing machine for your aluminium wire production line, there are several factors to consider to ensure you choose the right one for your specific needs. One of the first things to consider is the size and capacity of the machine. You will need to determine the maximum diameter of the wire you will be drawing, as well as the desired final diameter. This will help you choose a machine that can handle the size and volume of wire you will be working with.

Another important factor to consider is the speed and efficiency of the machine. A faster machine will be able to produce more wire in less time, increasing your overall productivity. Look for a machine that offers variable speed control, so you can adjust the speed to meet your production requirements.

In addition to size and speed, it is also important to consider the quality and durability of the machine. Look for a machine that is made from high-quality materials and has a solid construction. This will ensure that the machine can withstand the rigors of daily use and provide reliable performance for years to come.

When shopping for a wet wire drawing machine, it is also important to consider the level of automation and control features. Some machines offer advanced automation features, such as digital controls and monitoring systems, which can help improve efficiency and reduce the risk of errors. Look for a machine that offers the level of automation that best suits your production needs.

Finally, consider the reputation and reliability of the manufacturer. Look for a company that has a proven track record of producing high-quality wire drawing machines and providing excellent customer service. Reading reviews and testimonials from other customers can help you gauge the reputation of a manufacturer and make an informed decision.

In conclusion, choosing the right wet wire drawing machine for your aluminium wire production line is essential for achieving high-quality results and maximizing productivity. Consider factors such as size, speed, quality, automation, and manufacturer reputation when making your decision. By taking the time to research and evaluate your options, you can find a machine that meets your specific needs and helps you achieve success in your wire production operations.