Table of Contents

Izinto eziluncedo zokuSebenzisa iNxibelela yeDrop eNqobileyo yokuThatha iNxibelelwano yeNsimbi yeKhabhoni ePhezulu

Iingcebiso zokuSebenza ngokuLungileyo kweNxibelela yeNxibelela yeNxibelelo yokuThatha iNtsimbi yeNsimbi yeKhabhoni ePhezulu

Ngaphezu kokuseta ngokufanelekileyo, ukugcinwa rhoqo kwe-coiler nako kubalulekile ekusebenzeni ngokufanelekileyo. Oku kubandakanya ukuhlolwa okuqhelekileyo komtshini naziphi na iimpawu zokugqoka okanye umonakalo, kunye nokuthambisa iindawo ezihambayo ukukhusela ukungqubuzana kunye nokuqinisekisa ukusebenza kakuhle. Ngokugcina i-coiler igcinwe kakuhle, abaqhubi banokunciphisa ixesha lokunciphisa kwaye bakhulise imveliso.

Enye ingcebiso ebalulekileyo yokusebenza ngokufanelekileyo kwe-coiler yokulahla ngokuthe nkqo kukubeka esweni ukunyanzeliswa kocingo njengoko luhlanganiswa. Ulawulo olululo loxinzelelo lubalulekile ekufezekiseni iikhoyili ezifanayo neziqinileyo, eziyimfuneko ekusetyenzweni komlambo kunye nolawulo lomgangatho. Abaqhubi kufuneka bajonge rhoqo izicwangciso zoxinzelelo kwaye benze uhlengahlengiso njengoko lufunekayo ukuze kuqinisekiswe ukubopha okuhambelanayo kulo lonke ixesha lokuveliswa kwemveliso.

Ngaphezu koko, abaqhubi kufuneka baqwalasele ngokukhawuleza isantya se-coiler ngokubhekiselele kwisantya socingo oluveliswayo. Kubalulekile ukugcina umlinganiselo wesantya ohambelanayo phakathi kwe-coiler kunye nomgca wokuvelisa ukukhusela imiba efana nokugqithisa okanye ukudibanisa ucingo. Ngokubeka iliso ngononophelo kunye nokulungelelanisa izicwangciso zesantya, abaqhubi banokuqinisekisa ukubethelwa ngokutyibilikayo kunye nokusebenza kakuhle kwe-carbon steel wire.

Ukongezelela, abaqhubi kufuneka bakhumbule i-spool okanye i-reel size isetyenziswe kwi-coiler. Ukusebenzisa i-spool yobungakanani obuchanekileyo kubalulekile ekufezekiseni ukwakheka kwekhoyili kunye nokuthintela imiba efana nokutyibilika okanye ukujika-jika okungalinganiyo. Abaqhubi kufuneka bajonge rhoqo ubungakanani be-spool kwaye benze uhlengahlengiso njengoko lufuneka ukuze kuqinisekiswe ukuphoswa kocingo olufanelekileyo.

Okokugqibela, uqeqesho olululo lwabaqhubi lungundoqo ekusebenzeni ngokufanelekileyo kwe-coiler yokuwa ngokuthe nkqo ekuthabatheni i-carbon steel high wire. Abaqhubi kufuneka bazi kakuhle ukusebenza komatshini, kunye neeprothokholi zokhuseleko kunye nezona ndlela zilungileyo zokugcinwa kunye nokulungisa iingxaki. Ngokubonelela ngoqeqesho olubanzi kubaqhubi, iinkampani zinokuqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle kwe-coiler kunye nokunciphisa umngcipheko wemiba yemveliso.

Ekuqukumbeleni, ukusebenza ngokufanelekileyo kwe-coiler yokulahla i-vertical drop for take-up high carbon steel wire ifuna ukuseta ngokufanelekileyo, rhoqo. ukugcinwa, ukubeka iliso kuxinzelelo kunye nesantya, ingqalelo kubungakanani be-spool, kunye noqeqesho olucokisekileyo lwabaqhubi. Ngokulandela la macebiso, abaqhubi banokwandisa imveliso kunye nomgangatho wenkqubo yokuvelisa ucingo, okukhokelela ekuphuculeni ukusebenza kakuhle kunye nenzuzo.

Tips for Efficient Operation of Vertical Drop Coiler for Take-Up High Carbon Steel Wire

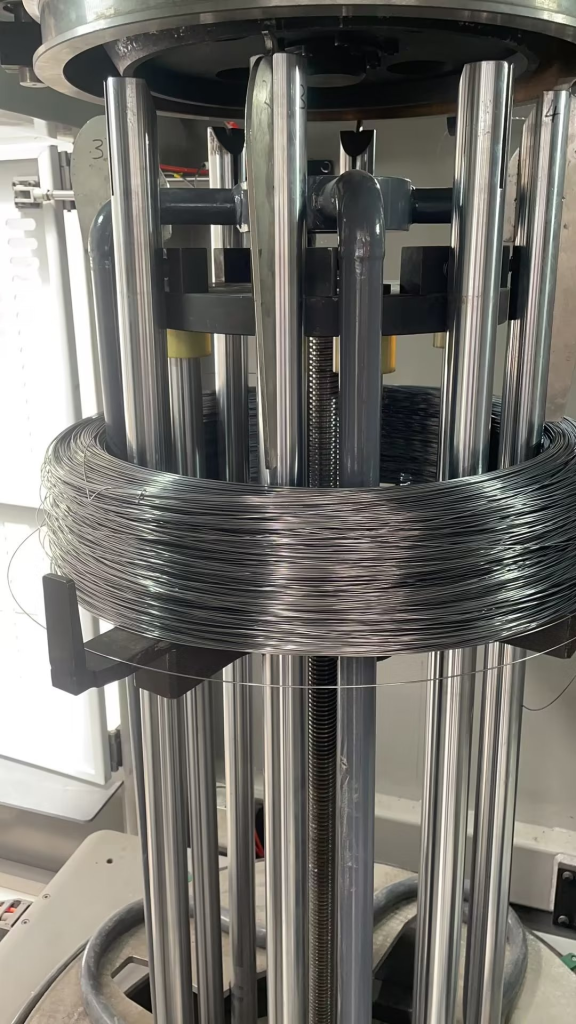

Vertical drop coilers are essential equipment in the wire manufacturing industry, particularly for high carbon steel wire. These machines are designed to efficiently coil wire onto a spool or reel as it is produced, ensuring smooth and continuous operation of the production line. To maximize the efficiency of a vertical drop coiler for take-up high carbon steel wire, there are several tips that operators should keep in mind.

First and foremost, it is crucial to ensure that the coiler is properly set up and calibrated before starting production. This includes adjusting the tension settings, speed controls, and other parameters to match the specific requirements of the wire being produced. Proper calibration will help prevent issues such as over-coiling or under-coiling, which can lead to production delays and quality issues.

In addition to proper setup, regular maintenance of the coiler is also essential for efficient operation. This includes routine inspections of the machine for any signs of wear or damage, as well as lubrication of moving parts to prevent friction and ensure smooth operation. By keeping the coiler well-maintained, operators can minimize downtime and maximize productivity.

Another important tip for efficient operation of a vertical drop coiler is to monitor the tension of the wire as it is being coiled. Proper tension control is crucial for achieving uniform and tightly wound coils, which are essential for downstream processing and quality control. Operators should regularly check the tension settings and make adjustments as needed to ensure consistent coiling throughout the production run.

Furthermore, operators should pay close attention to the speed of the coiler in relation to the speed of the wire being produced. It is important to maintain a consistent speed ratio between the coiler and the production line to prevent issues such as over-coiling or tangling of the wire. By carefully monitoring and adjusting the speed settings, operators can ensure smooth and efficient coiling of the high carbon steel wire.

Additionally, operators should be mindful of the spool or reel size being used on the coiler. Using the correct size spool is essential for achieving optimal coil formation and preventing issues such as slippage or uneven winding. Operators should regularly check the spool size and make adjustments as needed to ensure proper coiling of the wire.

Lastly, proper training of operators is key to efficient operation of a vertical drop coiler for take-up high carbon steel wire. Operators should be well-versed in the operation of the machine, as well as safety protocols and best practices for maintenance and troubleshooting. By providing comprehensive training to operators, companies can ensure smooth and efficient operation of the coiler and minimize the risk of production issues.

In conclusion, efficient operation of a vertical drop coiler for take-up high carbon steel wire requires proper setup, regular maintenance, monitoring of tension and speed, attention to spool size, and thorough operator training. By following these tips, operators can maximize the productivity and quality of their wire manufacturing process, leading to improved efficiency and profitability.