Ukuqonda ngokuSebenzisa umatshini wokuzoba ngocingo olulomileyo

Ngaphezu koko, oomatshini bokuzoba ngocingo olomileyo kulula ukuyigcina nokusebenza xa kuthelekiswa noomatshini abamanzi. Ekubeni kungekho zithambisi ezibandakanyekayo, kukho umngcipheko omncinci wokungcoliseka kunye nemiba yokugcinwa kwezinto ezinokuvela ekusebenziseni izithambiso. Oku kubangela ukunciphisa ixesha lokunciphisa kunye neendleko eziphantsi zokugcinwa, okuvumela abavelisi ukuba bakhulise imveliso yabo kunye nokusebenza kakuhle.

Ngaphezu kwezi nzuzo, oomatshini bokudweba ucingo olulomileyo banikezela ukuguquguquka okukhulu kunye nokuguquguquka ngokubhekiselele kwimveliso yocingo. Ziyakwazi ukulungelelaniswa lula ukulungiselela ubungakanani obuhlukeneyo bocingo kunye nezixhobo, ukuvumela abavelisi ukuba bavelise uluhlu olubanzi lweemveliso zocingo ukuhlangabezana neemfuno ezithile zabathengi babo. Oku kubhetyebhetye kwenza oomatshini bohlobo olomileyo lube lutyalo-mali oluxabisekileyo kubavelisi abafuna ukwandisa imveliso yabo yemveliso kwaye bangene kwiimarike ezintsha.

Kuko konke, ukusetyenziswa komatshini wokudweba ucingo olulomileyo lubonelela ngeenzuzo ezininzi kubavelisi abafuna ukuphucula umgangatho, ukusebenza kakuhle, kunye nokuzinza. yeenkqubo zabo zokuvelisa ucingo. Ukusuka kumgangatho ophezulu womgangatho ophezulu kunye nokusebenza kwamandla ukuze kube lula ukugcinwa kunye nokuguquguquka okukhulu, oomatshini bohlobo olomileyo babonelela ngesisombululo esisebenzayo kunye nesingqongileyo sokuvelisa iimveliso zocingo eziphezulu. Njengoko imfuno yeemveliso zocingo iqhubeka nokukhula kumashishini ahlukeneyo, ukutyala imali kumatshini wokuzoba ngocingo olomileyo kunokunceda abavelisi bahlale bekhuphisana kwaye bahlangabezane neemfuno eziguqukayo zabathengi babo.

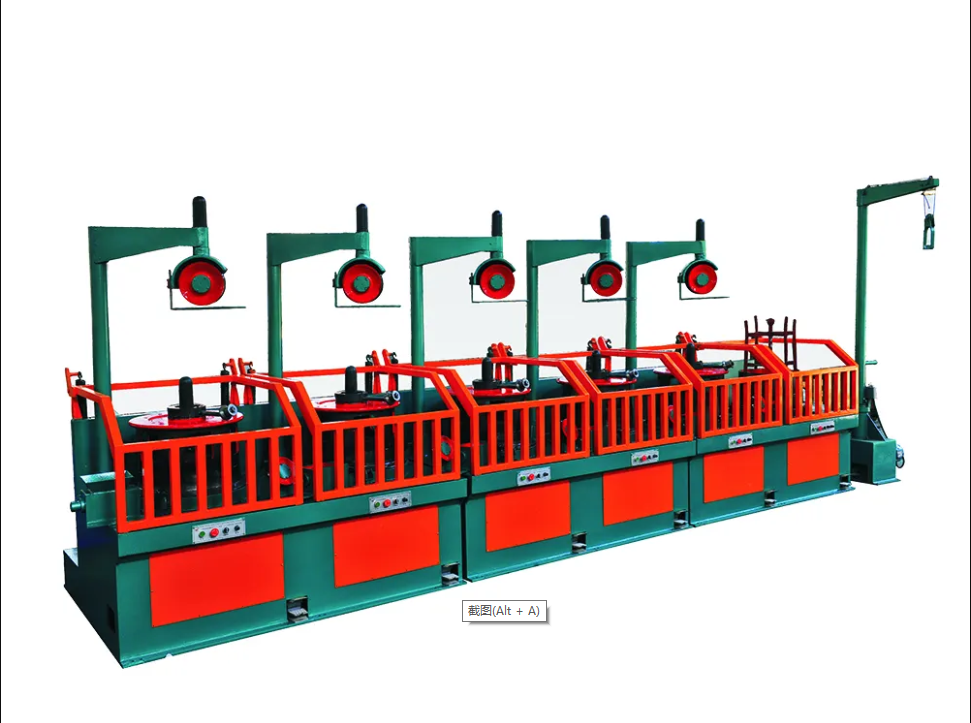

One of the key benefits of using a Dry Type Wire Drawing Machine is its ability to produce wire with a higher surface quality. Since there are no lubricants involved in the drawing process, the wire produced by a dry type machine is cleaner and free from any residue that may affect its performance. This results in a smoother surface finish and improved mechanical properties, making the wire suitable for a wide range of applications in industries such as automotive, construction, and electronics.

Another advantage of using a OTO Type Wire Drawing Machine is its energy efficiency. Traditional wet drawing machines require a significant amount of energy to operate due to the need for lubricants and cooling systems. In contrast, dry type machines operate at lower temperatures and do not require any additional cooling, resulting in reduced energy consumption and lower operating costs. This makes them a more sustainable option for manufacturers looking to reduce their carbon footprint and energy expenses.

Furthermore, dry type wire drawing machines are easier to maintain and operate compared to wet drawing machines. Since there are no lubricants involved, there is less risk of contamination and maintenance issues that may arise from the use of lubricants. This results in reduced downtime and lower maintenance costs, allowing manufacturers to increase their productivity and efficiency.

In addition to these benefits, dry type wire drawing machines offer greater flexibility and versatility in terms of wire production. They can be easily adjusted to accommodate different wire sizes and materials, allowing manufacturers to produce a wide range of wire products to meet the specific requirements of their customers. This flexibility makes dry type machines a valuable investment for manufacturers looking to expand their product offerings and enter new markets.

Overall, the use of a dry type wire drawing machine offers numerous benefits for manufacturers looking to improve the quality, efficiency, and sustainability of their wire production processes. From higher surface quality and energy efficiency to easier maintenance and greater flexibility, dry type machines provide a cost-effective and environmentally friendly solution for producing high-quality wire products. As the demand for wire products continues to grow in various industries, investing in a dry type wire drawing machine can help manufacturers stay competitive and meet the evolving needs of their customers.