Table of Contents

Izinto eziluncedo zokuSebenzisa umatshini wokuzoba ngocingo lohlobo olumanzi

Enye yeenzuzo eziphambili zokusebenzisa umatshini wokudweba ucingo olumanzi kukukwazi ukunciphisa ukungqubuzana ngexesha lenkqubo yokudweba ucingo. Kumatshini wokudweba ucingo olumanzi, ucingo lutsalwa nge-lubricant okanye i-coolant, enceda ukunciphisa ukushisa okwenziwa ngexesha lenkqubo. Oku akuncedi kuphela ukukhusela ucingo emonakalweni kodwa kwakhona kuqinisekisa inkqubo yokuzoba elula kwaye esebenzayo. Ukukhuhlana okuncitshisiweyo kukwanceda ukwandisa ubomi bokufa obusetyenziswa kumatshini, okukhokelela kwiindleko zokugcinwa okuphantsi kunye nokwanda kwemveliso.

Enye inzuzo yokusebenzisa umatshini wokudweba ucingo olumanzi kukukwazi ukuvelisa iingcingo ezinomphezulu ophezulu. I-lubricant okanye i-coolant esetyenziswe kumatshini inceda ukususa nakuphi na ukungafezeki komphezulu kucingo, okukhokelela ekugqityweni okugudileyo kunye nokugudiswa ngakumbi. Oku kubaluleke kakhulu kwizicelo apho ukubonakala kocingo kubalulekile, njengokuvelisa ubucwebe okanye i-fine wire mesh. Ukugqitywa komphezulu ophezulu kukwanceda ekuphuculeni umgangatho uwonke wocingo, okwenza ukuba lufaneleke ngakumbi ukusetyenziswa kwizicelo ezichanekileyo.

Ngaphezu kokunciphisa ukukhuhlana kunye nokuphucula umphezulu wokugqiba, umatshini wokuzoba uhlobo olumanzi lunika ulawulo olungcono phezu kwecingo. inkqubo yokuzoba. I-lubricant okanye i-coolant esetyenziswe kumatshini inokulungiswa ukuze ihambelane neemfuno ezithile zesicelo, ivumela ukuchaneka okukhulu kunye nokuhambelana kwinkqubo yokudweba ucingo. Eli nqanaba lolawulo libaluleke kakhulu kwizicelo apho ukunyamezela okuqinileyo kuyadingeka, njengokuveliswa kwezixhobo zonyango okanye izixhobo ze-aerospace. Ukukwazi ukuhlengahlengisa i-lubricant okanye i-coolant ikwavumela ukuguquguquka okukhulu kwiintlobo zeengcingo ezinokuveliswa, ukwenza umatshini ulungele uluhlu olubanzi lwezicelo.

kwezinye iintlobo zoomatshini bokuzoba ngocingo. Ukusetyenziswa kwe-lubricant okanye into yokupholisa kunceda ekunciphiseni ubushushu obuveliswa ngexesha lenkqubo yokuzoba ucingo, nto leyo enciphisa ukusetyenziswa kwamandla. Ukongeza, isithambiso okanye isisipholisi sinokuphinda sisetyenziswe kwakhona, sinciphise ngakumbi inkunkuma kunye neempembelelo zokusingqongileyo. Oku kwenza umatshini wokudweba ucingo olumanzi lube lukhetho oluzinzileyo ngakumbi kubakhiqizi abafuna ukunciphisa i-carbon footprint kwaye basebenze ngokufanelekileyo.

Ekuqukumbeleni, umatshini wokudweba ucingo olumanzi unika iingenelo ezininzi ngaphezu kwezinye iintlobo zoomatshini bokuzoba ngocingo. Ukususela ekunciphiseni ukungqubuzana kunye nokuphucula umgangatho wokugqiba ukubonelela ngolawulo olungcono malunga nenkqubo yokudweba ucingo kunye nokuhambelana nokusingqongileyo, umatshini wokudweba ucingo lohlobo olumanzi lukhetho oluguquguqukayo nolusebenzayo kubavelisi abafuna ukuvelisa iingcingo ezikumgangatho ophezulu kwizicelo ezininzi.

Iingcebiso zoLondolozo loMshini woMzobo weNxibelelwano olumanzi

Okokugqibela, kubalulekile ukuba ulandele ishedyuli yolondolozo ekhuthazwa ngumenzi kumatshini wokudweba ucingo olumanzi. Imisebenzi yokugcinwa rhoqo, njengokucoca, ukuhlola, ukuthambisa, kunye nokutshintshwa kwesipholisi, kufuneka kwenziwe ngamaxesha athile ukuthintela ukuguga kwangaphambili kunye nomonakalo kumatshini. ukusebenza kwayo ngeyona ndlela kunye nokuphila ixesha elide. Ukucoca rhoqo, ukuhlolwa, ukuthambisa, ukugcinwa kokupholisa, kunye nokubeka iliso kuxinzelelo kunye nokulungelelaniswa ziingcebiso eziphambili zokugcina umatshini ukwimeko ephezulu. Ngokulandela ezi ngcebiso zogcino kunye nezikhokelo zomenzi, unokwandisa ubomi bomatshini wakho wokuzoba ngocingo olumanzi kwaye uqinisekise ngomgangatho ophezulu wocingo olutsaliweyo kwiinkqubo zakho zokwenza.

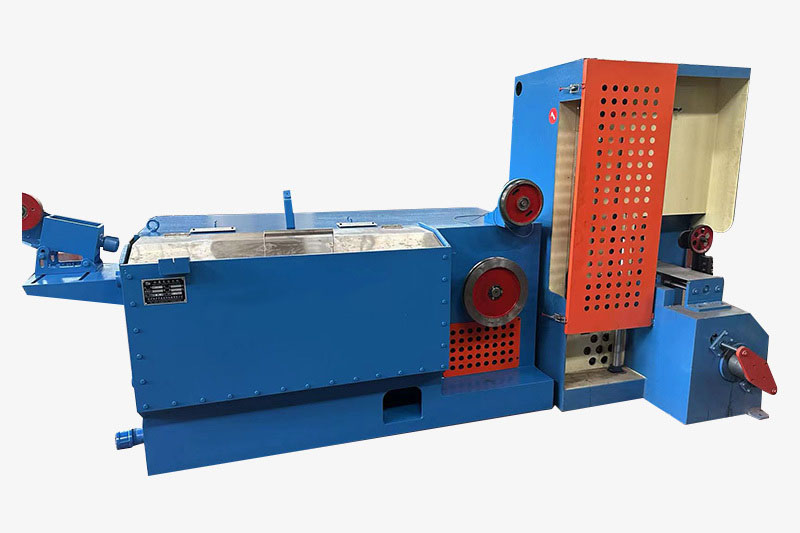

Wire drawing machines are essential equipment in the manufacturing industry, used to reduce the diameter of wire by pulling it through a series of dies. One common type of wire drawing machine is the Wet Type Wire Drawing Machine, which uses a coolant to reduce friction and heat during the drawing process. Proper maintenance of a wet type wire drawing machine is crucial to ensure its optimal performance and longevity. In this article, we will discuss some maintenance tips for wet type wire drawing machines.

Regular cleaning and inspection of the machine are essential to prevent any build-up of dirt, debris, or coolant residue that can affect its performance. Start by turning off the machine and disconnecting it from the power source. Use a clean cloth or brush to remove any dirt or debris from the machine’s exterior and interior components. Pay special attention to the dies, rollers, and coolant system, as these are the areas most prone to build-up.

After cleaning, inspect the machine for any signs of wear or damage. Check the dies for any cracks or chips, as these can affect the quality of the drawn wire. Inspect the rollers for any signs of wear or misalignment, as this can cause uneven drawing and wire breakage. Check the coolant system for any leaks or blockages, as proper coolant circulation is essential for reducing friction and heat during the drawing process.

In addition to regular cleaning and inspection, it is important to lubricate the machine’s moving parts to ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer and apply it to the dies, rollers, and other moving components. Be sure to follow the manufacturer’s guidelines for the type and frequency of lubrication to prevent over-lubrication, which can attract dirt and debris.

Another important maintenance tip for wet type wire drawing machines is to monitor the coolant levels and quality regularly. Check the coolant reservoir and top it up if necessary to ensure proper coolant circulation. Inspect the coolant for any signs of contamination, such as dirt, debris, or metal particles, and replace it if needed. Proper coolant maintenance is crucial for reducing friction and heat during the drawing process and extending the life of the machine’s components.

It is also important to check the tension and alignment of the wire during the drawing process. Improper tension or alignment can cause wire breakage or uneven drawing, affecting the quality of the drawn wire. Adjust the tension and alignment as needed to ensure smooth and consistent drawing.

Lastly, it is important to follow the manufacturer’s recommended maintenance schedule for the wet type wire drawing machine. Regular maintenance tasks, such as cleaning, inspection, lubrication, and coolant replacement, should be performed at specified intervals to prevent premature wear and damage to the machine.

In conclusion, proper maintenance of a wet type wire drawing machine is essential to ensure its optimal performance and longevity. Regular cleaning, inspection, lubrication, coolant maintenance, and monitoring of tension and alignment are key maintenance tips for keeping the machine in top condition. By following these maintenance tips and the manufacturer’s guidelines, you can extend the life of your wet type wire drawing machine and ensure high-quality drawn wire for your manufacturing processes.