Merits of Using Automated Wire Cutting Machines in Welding Electrode Plants

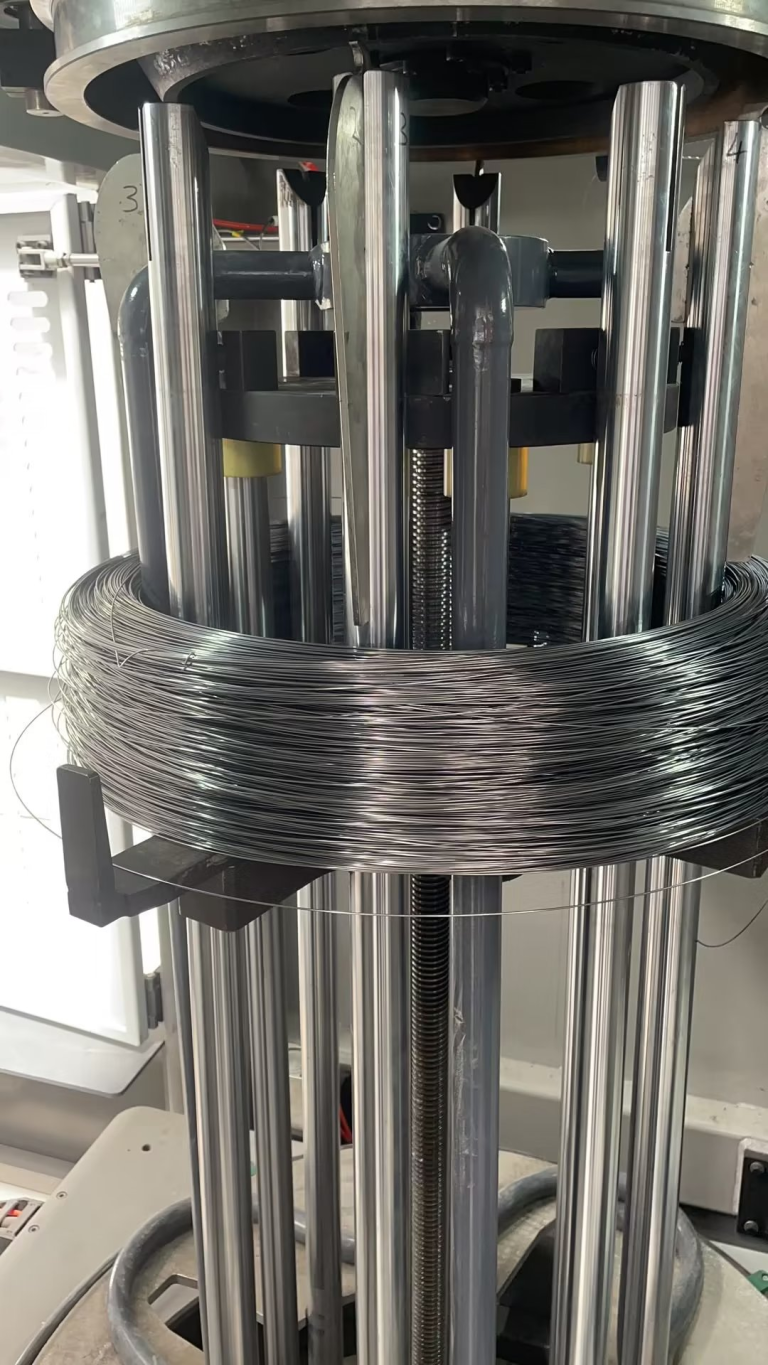

Welding Electrode Plant Wire Cutting Machines play a crucial role in the manufacturing of welding electrodes, which are essential components in various industries such as construction, automotive, and manufacturing. One of the key processes in welding electrode production is wire cutting, which involves cutting metal wires to specific lengths for use in the electrodes. Traditionally, wire cutting was done manually, which was time-consuming and labor-intensive. However, with the advancement of technology, automated wire cutting machines have become increasingly popular in welding electrode plants.

Automated wire cutting machines offer a wide range of benefits that make them a valuable investment for welding electrode plants. One of the primary advantages of using automated wire cutting machines is increased efficiency. These machines are capable of cutting wires at a much faster rate than manual cutting, which helps to streamline the production process and increase overall productivity. This efficiency is particularly important in welding electrode plants, where large quantities of electrodes are produced on a daily basis.

In addition to improved efficiency, automated wire cutting machines also offer greater precision and accuracy in cutting wires. These machines are equipped with advanced cutting mechanisms that ensure each wire is cut to the exact length required, with minimal margin for error. This precision is essential in welding electrode production, as even small variations in wire length can affect the quality and performance of the electrodes.

Another benefit of using automated wire cutting machines in welding electrode plants is the reduction of waste. Manual wire cutting often results in a significant amount of scrap material due to human error or inconsistencies in cutting. Automated machines, on the other hand, are programmed to optimize the use of materials and minimize waste, leading to cost savings for the plant in the long run.

Furthermore, automated wire cutting machines help to improve workplace safety in welding electrode plants. Manual wire cutting can be a hazardous task, as it involves handling sharp metal wires and operating cutting tools. By automating this process, plant workers are exposed to fewer risks and potential injuries, creating a safer working environment for all employees.

Additionally, automated wire cutting machines are versatile and can be easily customized to meet the specific needs of a welding electrode plant. These machines can be programmed to cut wires of different materials, sizes, and shapes, allowing for greater flexibility in production. This adaptability is particularly beneficial for plants that produce a variety of welding electrodes for different applications.

Overall, the benefits of using automated wire cutting machines in welding electrode plants are clear. From increased efficiency and precision to reduced waste and improved safety, these machines offer a range of advantages that can help plants enhance their production processes and stay competitive in the market. As technology continues to advance, automated wire cutting machines will likely become an indispensable tool in the manufacturing of welding electrodes, providing plants with the means to meet the growing demand for high-quality welding products.