Table of Contents

How to Properly Maintain and Troubleshoot Vertical Type Payoff Unit for Wire Drawing Process

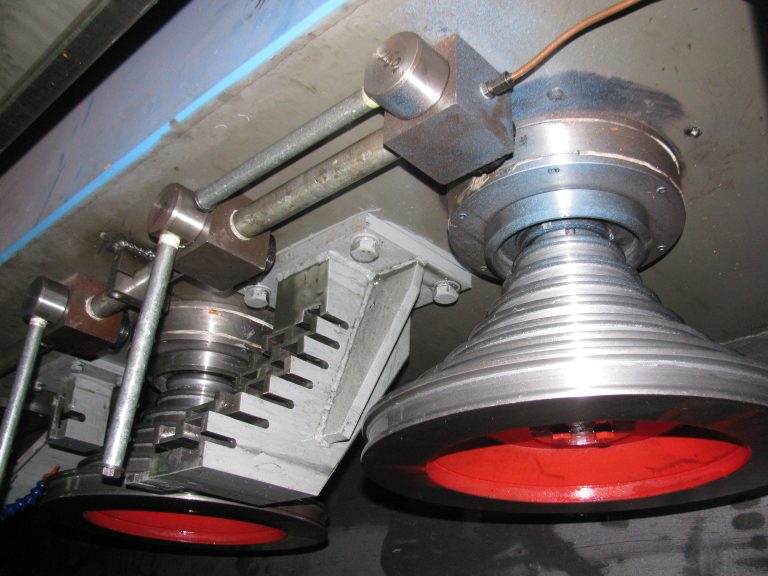

In the wire drawing process, the Vertical Payoff For Wire Drawing Machine unit plays a crucial role in ensuring the smooth and efficient operation of the production line. This unit is responsible for supplying the wire to the drawing machine, and any issues with its performance can lead to downtime and decreased productivity. Proper maintenance and troubleshooting of the vertical type payoff unit are essential to prevent costly breakdowns and delays in production.

One of the key aspects of maintaining the vertical type payoff unit is regular inspection and cleaning. Over time, dust, dirt, and debris can accumulate on the unit, causing it to operate less efficiently. By regularly inspecting and cleaning the unit, you can prevent these issues and ensure that it continues to function properly. Additionally, lubricating the moving parts of the unit can help reduce friction and wear, extending its lifespan and improving its performance.

Another important maintenance task for the vertical type payoff unit is checking and adjusting the tension of the wire. Proper tension is crucial for ensuring that the wire is fed smoothly into the drawing machine without any snags or breaks. By regularly checking and adjusting the tension of the wire, you can prevent issues such as wire slippage or breakage, which can lead to costly downtime and repairs.

In addition to regular maintenance, troubleshooting the vertical type payoff unit is also essential for identifying and resolving any issues that may arise. One common issue that can occur with the unit is misalignment, which can cause the wire to feed unevenly into the drawing machine. By carefully inspecting the unit and adjusting the alignment as needed, you can prevent this issue and ensure that the wire is fed smoothly and evenly.

Another common issue that can occur with the vertical type payoff unit is motor failure. If the motor fails, the unit will be unable to feed the wire into the drawing machine, leading to downtime and decreased productivity. By regularly checking the motor for signs of wear or damage and replacing it as needed, you can prevent motor failure and keep the unit running smoothly.

In conclusion, proper maintenance and troubleshooting of the vertical type payoff unit are essential for ensuring the smooth and efficient operation of the wire drawing process. By regularly inspecting and cleaning the unit, checking and adjusting the tension of the wire, and troubleshooting common issues such as misalignment and motor failure, you can prevent costly breakdowns and delays in production. By taking the time to properly maintain and troubleshoot the vertical type payoff unit, you can ensure that your wire drawing process runs smoothly and efficiently, maximizing productivity and minimizing downtime.

Advantages of Using Vertical Type Payoff Unit for Wire Drawing Process

The wire drawing process is a crucial step in the production of various types of wire products, such as electrical wires, cables, and fencing. One of the key components in this process is the payoff unit, which is responsible for supplying the wire to the drawing machine. There are different types of payoff units available, with the vertical type being one of the most popular choices among manufacturers. In this article, we will discuss the advantages of using a vertical type payoff unit for the wire drawing process.

One of the main advantages of a Overhead Payoff unit is its space-saving design. Unlike horizontal payoff units, which require a significant amount of floor space, vertical units are mounted on a vertical frame, allowing for a more compact footprint. This is especially beneficial for manufacturers with limited space in their production facilities, as it allows them to maximize the use of available space.

Another advantage of vertical type payoff units is their ease of operation. These units are designed to be user-friendly, with controls and adjustments easily accessible to operators. This makes it easier for operators to set up and monitor the wire drawing process, leading to increased efficiency and productivity. Additionally, vertical payoff units are typically equipped with safety features to protect operators from potential hazards, further enhancing the overall safety of the production process.

In addition to space-saving design and ease of operation, vertical type payoff units offer improved wire tension control. The vertical orientation of the unit allows for better control over the tension of the wire as it is fed into the drawing machine. This is important for ensuring consistent quality and performance of the finished wire products. By maintaining proper tension throughout the drawing process, manufacturers can reduce the risk of defects and improve the overall quality of their products.

Furthermore, vertical type payoff units are known for their versatility. These units can accommodate a wide range of wire sizes and types, making them suitable for a variety of applications. Whether manufacturers are producing thin electrical wires or thick fencing wires, a vertical type payoff unit can be easily adjusted to meet their specific requirements. This flexibility allows manufacturers to adapt to changing production needs and produce a diverse range of wire products with ease.

Overall, the advantages of using a vertical type payoff unit for the wire drawing process are clear. From space-saving design and ease of operation to improved wire tension control and versatility, these units offer numerous benefits to manufacturers. By investing in a vertical type payoff unit, manufacturers can enhance the efficiency, safety, and quality of their wire drawing process, ultimately leading to greater success in the production of wire products.