Table of Contents

Tips for Proper Maintenance and Care of Vertical Wire Drop Coiler

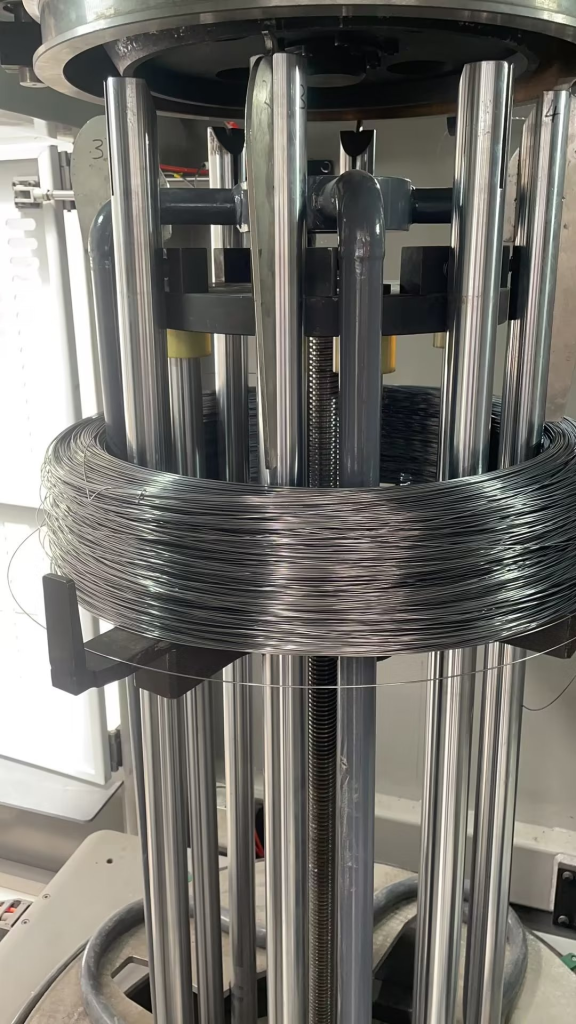

A vertical wire drop coilers are used to coil wire into a neat and organized manner, making it easier to transport and store. Proper maintenance and care of the vertical wire drop coiler are essential to ensure its longevity and efficiency. In this article, we will discuss some tips for maintaining and caring for your vertical wire drop coiler.

First and foremost, it is important to regularly inspect the vertical wire drop coiler for any signs of wear and tear. Check for loose or damaged parts, such as belts, pulleys, and bearings. Replace any worn-out parts immediately to prevent further damage to the machine. Regular inspections can help identify potential issues before they escalate into major problems.

In addition to regular inspections, it is important to keep the vertical wire drop coiler clean and free of debris. Dust, dirt, and other contaminants can build up on the machine over time, causing it to operate less efficiently. Use a soft brush or cloth to remove any debris from the machine regularly. Avoid using harsh chemicals or abrasive materials, as they can damage the machine’s components.

Another important aspect of maintaining a vertical wire drop coiler is lubrication. Proper lubrication of the machine’s moving parts is essential to ensure smooth operation. Use a high-quality lubricant recommended by the manufacturer to lubricate the machine’s bearings, pulleys, and other moving parts. Be sure to follow the manufacturer’s guidelines for lubrication frequency and quantity to prevent over-lubrication or under-lubrication.

In addition to regular maintenance tasks, it is important to operate the vertical wire drop coiler correctly to prevent unnecessary wear and tear. Avoid overloading the machine beyond its capacity, as this can cause strain on the motor and other components. Follow the manufacturer’s guidelines for wire diameter and coil size to ensure optimal performance.

Proper storage of the vertical wire drop coiler is also important for maintaining its longevity. Store the machine in a clean, dry, and well-ventilated area to prevent rust and corrosion. Cover the machine when not in use to protect it from dust and debris. Avoid storing the machine near sources of heat or moisture, as this can damage its components.

Regular maintenance and care of a vertical wire drop coiler are essential to ensure its longevity and efficiency. By following these tips, you can keep your machine in top condition and prevent costly repairs or replacements. Remember to inspect the machine regularly, keep it clean and lubricated, operate it correctly, and store it properly. With proper maintenance and care, your vertical wire drop coiler will continue to serve you well for years to come.

Advantages of Using Vertical Wire Drop Coiler in Industrial Applications

In industrial applications where wire coiling is necessary, the use of a Vertical Drop Coiler can offer numerous advantages. This specialized piece of equipment is designed to efficiently and effectively coil wire in a vertical orientation, making it ideal for a variety of industrial settings. In this article, we will explore the advantages of using a vertical wire drop coiler in industrial applications.

One of the primary advantages of using a vertical wire drop coiler is its space-saving design. Unlike horizontal wire coilers that require a large footprint, vertical wire drop coilers can be installed in tight spaces, making them ideal for facilities with limited floor space. This compact design allows for greater flexibility in layout and can help optimize the use of available space in industrial settings.

Additionally, vertical wire drop coilers are known for their high-speed operation. These machines are capable of coiling wire at a rapid pace, increasing productivity and efficiency in industrial applications. The high-speed operation of vertical wire drop coilers can help reduce production time and labor costs, making them a cost-effective solution for wire coiling needs.

Another advantage of using a vertical wire drop coiler is its versatility. These machines are designed to accommodate a wide range of wire sizes and types, making them suitable for a variety of industrial applications. Whether coiling thin gauge wire or heavy-duty cable, vertical wire drop coilers can handle the job with precision and accuracy.

In addition to their space-saving design, high-speed operation, and versatility, vertical wire drop coilers are also known for their durability and reliability. These machines are built to withstand the rigors of industrial use, ensuring consistent performance and minimal downtime. With proper maintenance and care, vertical wire drop coilers can provide years of reliable service, making them a valuable investment for industrial facilities.

Furthermore, vertical wire drop coilers offer enhanced safety features to protect operators and prevent accidents in the workplace. These machines are equipped with safety guards, emergency stop buttons, and other safety mechanisms to ensure safe operation at all times. By prioritizing safety, vertical wire drop coilers help create a secure working environment for employees and reduce the risk of injuries on the job.

In conclusion, the advantages of using a vertical wire drop coiler in industrial applications are numerous. From their space-saving design and high-speed operation to their versatility, durability, and safety features, vertical wire drop coilers offer a range of benefits that make them an ideal choice for wire coiling needs. Whether coiling wire for manufacturing, construction, or other industrial applications, vertical wire drop coilers can help streamline operations, increase productivity, and improve overall efficiency in the workplace. Consider incorporating a vertical wire drop coiler into your industrial facility to experience these advantages firsthand.