Table of Contents

Advantages of Using Vertical Drop Coiler in Wire and Cable Manufacturing

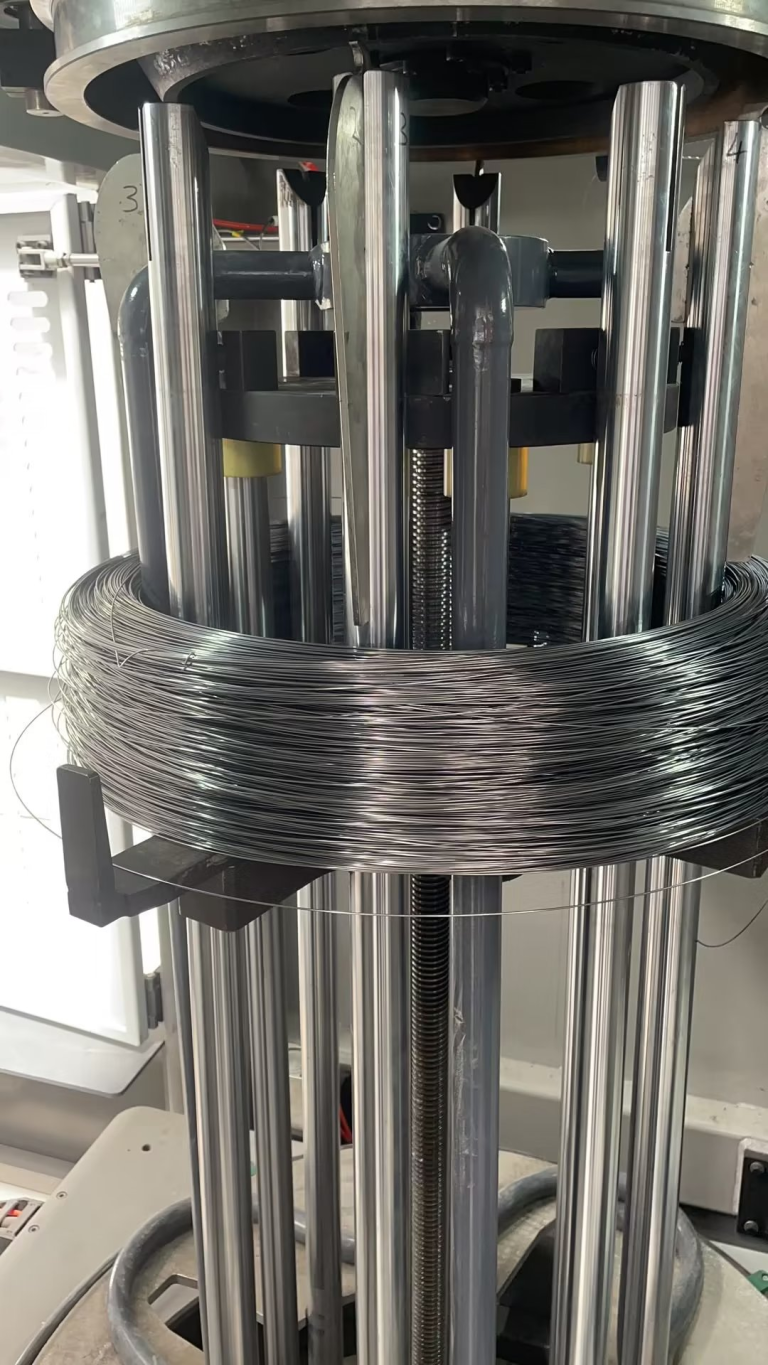

In the world of wire and cable manufacturing, efficiency and precision are key factors in ensuring high-quality products. One piece of equipment that plays a crucial role in this process is the vertical drop coiler. This innovative machine offers a range of advantages that make it a popular choice for manufacturers looking to streamline their production processes.

One of the primary advantages of using a vertical drop coiler is its ability to coil wire or cable quickly and efficiently. The vertical design of the machine allows for a straight downward drop of the coiled product, eliminating the need for complex winding mechanisms. This results in faster coil times and increased productivity, ultimately leading to cost savings for manufacturers.

Additionally, the vertical drop coiler offers superior control over the coiling process. The machine can be easily adjusted to accommodate different wire or cable sizes, ensuring that each coil is wound with precision and consistency. This level of control is essential for maintaining product quality and meeting the specific requirements of customers.

Another key advantage of the vertical drop coiler is its compact footprint. Unlike traditional coiling machines that require a large amount of floor space, the vertical drop coiler can be easily integrated into existing production lines without taking up valuable real estate. This space-saving design allows manufacturers to optimize their workspace and increase overall efficiency.

Furthermore, the vertical drop coiler is designed for ease of use and maintenance. The machine features simple controls and intuitive operation, making it accessible to operators of all skill levels. Additionally, the vertical design of the coiler minimizes the risk of tangles or snags during the coiling process, reducing downtime and maintenance costs.

In addition to its practical advantages, the vertical drop coiler also offers environmental benefits. The machine is designed to minimize waste and reduce energy consumption, making it a sustainable choice for manufacturers looking to reduce their carbon footprint. By optimizing the coiling process and maximizing efficiency, the vertical drop coiler helps to minimize material waste and energy usage, ultimately contributing to a more sustainable manufacturing process.

Overall, the vertical drop coiler is a versatile and efficient machine that offers a range of advantages for wire and cable manufacturers. From its fast and precise coiling capabilities to its compact footprint and ease of use, this innovative machine is a valuable asset for any production line. By investing in a vertical drop coiler, manufacturers can improve productivity, enhance product quality, and reduce costs, ultimately gaining a competitive edge in the industry.

How to Properly Maintain and Troubleshoot Vertical Drop Coiler Systems

Vertical drop coilers are an essential component in many industrial processes, particularly in the wire and cable manufacturing industry. These systems are responsible for coiling wire or cable onto a spool in a controlled and efficient manner. Proper maintenance and troubleshooting of vertical drop coiler systems are crucial to ensure smooth operation and prevent costly downtime.

One of the key maintenance tasks for Vertical Wire Drop Coiler is regular cleaning and lubrication of moving parts. Dust, dirt, and debris can accumulate on the coiling mechanism over time, leading to increased friction and wear. This can result in decreased efficiency and potential damage to the equipment. By regularly cleaning and lubricating the coiler, you can extend its lifespan and ensure optimal performance.

In addition to cleaning and lubrication, it is important to inspect the coiler for any signs of wear or damage. Check for loose or worn parts, such as belts, bearings, and springs, and replace them as needed. Inspect the spooling mechanism for any signs of misalignment or damage, as this can affect the quality of the coiled wire or cable. By conducting regular inspections, you can identify and address potential issues before they escalate into major problems.

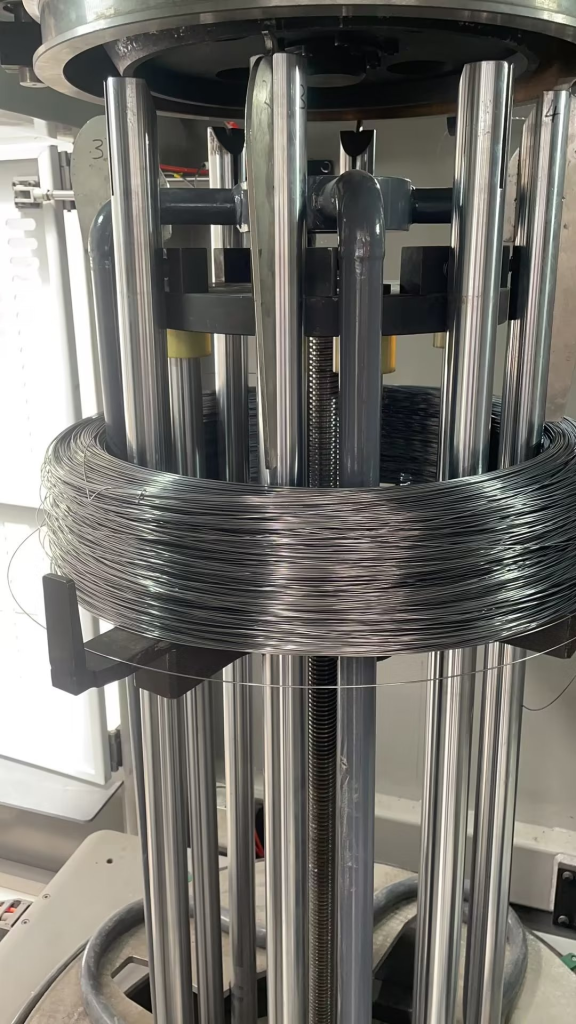

Another important aspect of maintaining vertical drop coiler systems is proper tension control. Tension plays a critical role in the coiling process, as it determines the tightness of the coil and the quality of the finished product. Improper tension can lead to uneven winding, slippage, or damage to the wire or cable. Make sure to adjust the tension settings according to the specifications of the material being coiled, and monitor the tension throughout the coiling process to ensure consistent results.

When troubleshooting vertical drop coiler systems, it is important to start by identifying the root cause of the issue. Common problems with coilers include misalignment, slippage, and jamming. If the coiler is not coiling the wire or cable properly, check for any obstructions or misalignments in the spooling mechanism. Make sure that the tension settings are correct and that the material is feeding smoothly into the coiler.

If the coiler is experiencing slippage or jamming, check for any worn or damaged parts that may be causing the issue. Inspect the drive system, including belts, pulleys, and gears, for any signs of wear or misalignment. Make sure that the drive system is properly tensioned and that all components are functioning correctly. If necessary, replace any worn or damaged parts to restore the coiler to optimal performance.

In conclusion, proper maintenance and troubleshooting of vertical drop coiler systems are essential for ensuring efficient operation and preventing costly downtime. By regularly cleaning, lubricating, and inspecting the coiler, you can extend its lifespan and maintain optimal performance. Pay close attention to tension control and adjust the settings as needed to achieve consistent results. When troubleshooting issues with the coiler, identify the root cause of the problem and address it promptly to prevent further damage. By following these guidelines, you can keep your vertical drop coiler system running smoothly and effectively for years to come.

The Impact of Vertical Drop Coiler Technology on Production Efficiency and Quality Control

Vertical drop coilers have revolutionized the way in which wire and cable manufacturers operate, significantly impacting production efficiency and quality control. This innovative technology allows for the automatic coiling of wire or cable directly from the extrusion line, eliminating the need for manual handling and reducing the risk of damage or defects. By seamlessly integrating into the production process, vertical drop coilers have become an essential tool for manufacturers looking to streamline their operations and improve overall product quality.

One of the key benefits of vertical drop coilers is their ability to increase production efficiency. By automating the coiling process, manufacturers can significantly reduce the time and labor required to coil wire or cable. This not only speeds up production times but also allows for greater output capacity, enabling manufacturers to meet increasing demand without sacrificing quality. Additionally, the consistent and precise coiling provided by vertical drop coilers ensures that each coil is uniform in size and shape, further enhancing production efficiency.

In addition to improving production efficiency, vertical drop coilers also play a crucial role in quality control. By eliminating manual handling, these coilers reduce the risk of damage or defects that can occur during the coiling process. This results in a higher quality end product that meets the strict standards of the industry. Furthermore, the automated nature of vertical drop coilers allows for real-time monitoring and adjustment of coiling parameters, ensuring that each coil meets the desired specifications. This level of control is essential for maintaining consistent quality across all products.

Another significant impact of vertical drop coiler technology is its ability to reduce waste and improve sustainability. By automating the coiling process, manufacturers can minimize the amount of scrap material generated during production. This not only reduces costs associated with waste disposal but also contributes to a more environmentally friendly manufacturing process. Additionally, the precise coiling provided by vertical drop coilers ensures that each coil is tightly wound, maximizing the use of materials and reducing the overall footprint of the product.

Overall, the adoption of vertical drop coiler technology has had a profound impact on the wire and cable manufacturing industry. By improving production efficiency, enhancing quality control, and reducing waste, these coilers have become an essential tool for manufacturers looking to stay competitive in a rapidly evolving market. As technology continues to advance, vertical drop coilers will likely play an even greater role in shaping the future of the industry, driving innovation and efficiency across the board. With their numerous benefits and proven track record, it is clear that vertical drop coilers are here to stay and will continue to revolutionize the way in which wire and cable products are manufactured.