Table of Contents

Comparison of Different straight line wire drawing machine Models

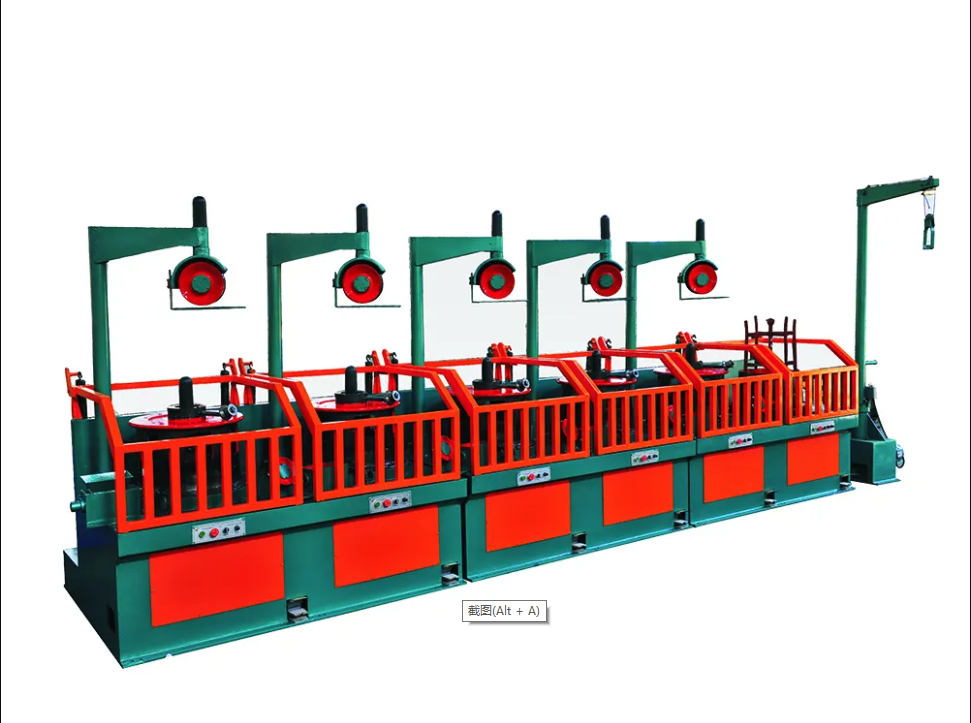

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of various products such as electrical wiring, cables, and fencing. Straight line wire drawing machines are a type of wire drawing machine that is used to draw wire in a straight line without any bending or twisting. There are several different models of straight line wire drawing machines available on the market, each with its own unique features and capabilities.

One popular model of straight line wire drawing machine is the single drum wire drawing machine. This machine consists of a single drum that rotates at high speeds to pull the wire through a series of dies. The wire is fed into the machine from a spool and is drawn through the dies to reduce its diameter. Single drum wire drawing machines are commonly used for drawing wire with larger diameters and are capable of producing high-quality wire with consistent dimensions.

Another common model of straight line wire drawing machine is the double drum wire drawing machine. This machine consists of two drums that rotate in opposite directions to pull the wire through the dies. The wire is fed into the machine from a spool and is drawn through the dies by the rotation of the drums. Double drum wire drawing machines are often used for drawing wire with smaller diameters and are capable of producing wire with very precise dimensions.

In addition to single drum and double drum wire drawing machines, there are also multi-drum wire drawing machines available on the market. These machines consist of multiple drums that rotate at different speeds to pull the wire through the dies. Multi-drum wire drawing machines are capable of drawing wire with a wide range of diameters and are often used in high-volume production settings.

When comparing different models of straight line wire drawing machines, there are several factors to consider. One important factor is the speed at which the machine can draw wire. Machines with higher drawing speeds are able to produce wire more quickly, which can be beneficial in high-volume production settings. Another factor to consider is the number of dies that the machine has. Machines with more dies are able to reduce the diameter of the wire more quickly and can produce wire with more precise dimensions.

It is also important to consider the overall quality and durability of the machine. Machines made from high-quality materials and with precision engineering are more likely to produce high-quality wire and have a longer lifespan. Additionally, it is important to consider the cost of the machine and whether it fits within your budget.

In conclusion, straight line wire drawing machines are an essential tool in the manufacturing of wire products. There are several different models of straight line wire drawing machines available on the market, each with its own unique features and capabilities. When comparing different models, it is important to consider factors such as drawing speed, number of dies, quality, durability, and cost. By carefully evaluating these factors, you can choose the right straight line wire drawing machine for your specific needs and production requirements.

Maintenance Tips for Straight Line Wire Drawing Machines

Straight line wire drawing machines are essential equipment in the manufacturing industry, used to produce wires of various diameters and lengths. These machines operate by pulling a wire through a series of dies to reduce its diameter and improve its surface finish. To ensure the smooth operation and longevity of Straight Line Wire Drawing Machine For Low Carbon Steel Wire, regular maintenance is crucial. In this article, we will discuss some maintenance tips to help you keep your machines running efficiently.

One of the most important maintenance tasks for straight line wire drawing machines is cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues. Pay special attention to the dies and rollers, as any buildup on these components can affect the quality of the wire being produced.

In addition to cleaning, lubrication is another key aspect of maintaining straight line wire drawing machines. Proper lubrication helps reduce friction between moving parts, preventing wear and tear and extending the machine’s lifespan. Be sure to use the recommended lubricants for each component, as using the wrong type of lubricant can cause damage. Check the lubrication levels regularly and top up as needed to ensure smooth operation.

Inspecting the machine for wear and tear is also essential for maintaining straight line wire drawing machines. Look for signs of damage or excessive wear on components such as dies, rollers, and bearings. Replace any worn or damaged parts promptly to prevent further damage to the machine and ensure consistent wire quality. Regular inspections can help identify potential issues before they escalate into major problems.

Another important maintenance tip for straight line wire drawing machines is to monitor the machine’s operating parameters. Keep an eye on factors such as wire tension, speed, and temperature to ensure they are within the recommended range. Adjust these parameters as needed to optimize the machine’s performance and prevent overheating or other issues. Regularly calibrating the machine’s settings can help maintain consistent wire quality and prevent production delays.

Lastly, scheduling regular maintenance checks with a qualified technician is crucial for keeping straight line wire drawing machines in top condition. A professional technician can perform more in-depth inspections and identify any potential issues that may not be apparent during routine maintenance. They can also provide recommendations for optimizing the machine’s performance and extending its lifespan.

In conclusion, proper maintenance is essential for ensuring the efficient operation and longevity of straight line wire drawing machines. By following these maintenance tips, you can keep your machines running smoothly and produce high-quality wires consistently. Remember to clean and lubricate the machine regularly, inspect for wear and tear, monitor operating parameters, and schedule regular maintenance checks with a qualified technician. With proper care and maintenance, your straight line wire drawing machines can continue to meet your production needs for years to come.