Table of Contents

Maintenance Tips for straight line wire drawing machines

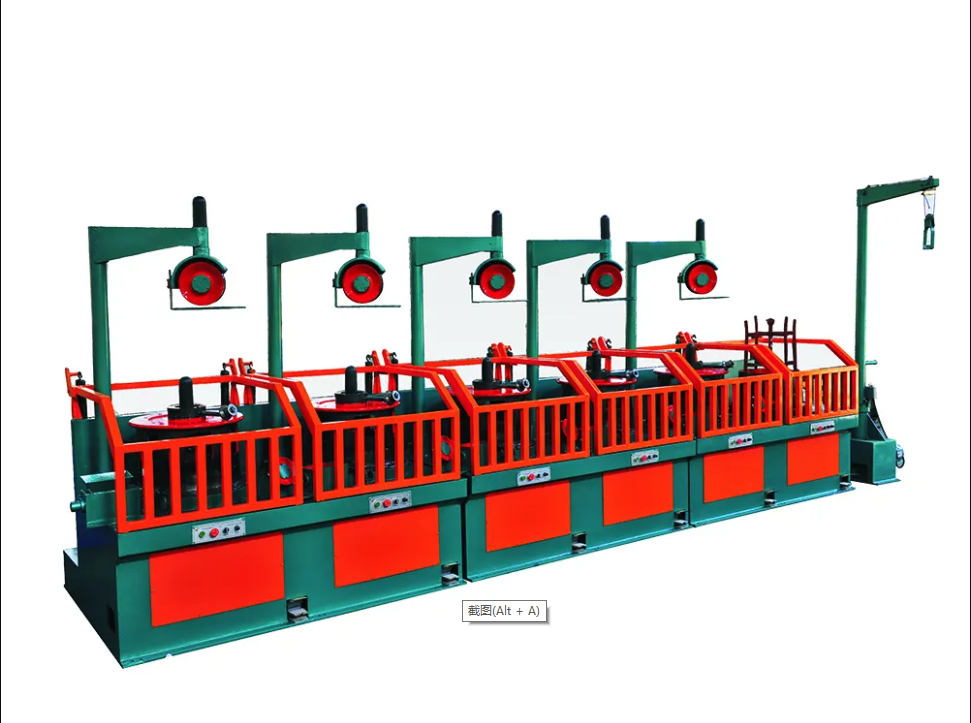

Straight line wire drawing machine is essential equipment in the manufacturing industry, used to produce wires of various diameters and lengths. These machines operate by pulling a wire through a series of dies to reduce its diameter and improve its surface finish. To ensure the smooth operation and longevity of straight line wire drawing machines, regular maintenance is crucial. In this article, we will discuss some maintenance tips to help you keep your machines running efficiently.

One of the most important maintenance tasks for straight line wire drawing machines is cleaning. Over time, dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. Regularly cleaning the machine with a soft brush or cloth can help prevent these issues. Pay special attention to the dies and rollers, as any buildup on these components can affect the quality of the wire being produced.

In addition to cleaning, lubrication is another key aspect of maintaining Pulley Type Wire Drawing Machine. Proper lubrication helps reduce friction between moving parts, preventing wear and tear and extending the machine’s lifespan. Be sure to use the recommended lubricants for each component, as using the wrong type can cause damage. Check the lubrication levels regularly and top up as needed to keep the machine running smoothly.

Inspecting the machine for any signs of wear or damage is also essential for maintenance. Look for any loose or worn parts, such as belts, bearings, or gears, and replace them as needed. Regularly checking for wear can help prevent more significant issues down the line and ensure the machine’s continued operation.

Another important maintenance tip for straight line wire drawing machines is to monitor the tension of the wire being drawn. Proper tension is crucial for producing high-quality wire, and fluctuations in tension can lead to inconsistencies in the finished product. Use a tension gauge to measure the wire tension regularly and make adjustments as needed to maintain a consistent pull.

Regularly calibrating the machine is also important for maintaining its performance. Over time, the machine’s settings can drift, affecting the quality of the wire being produced. Check the calibration of the machine’s speed, tension, and other settings regularly and make any necessary adjustments to ensure accurate operation.

Finally, scheduling regular maintenance checks with a qualified technician can help identify any potential issues before they become major problems. A professional inspection can catch issues early on and prevent costly downtime and repairs. Consider setting up a maintenance schedule to ensure that your straight line wire drawing machines are always in top condition.

In conclusion, proper maintenance is essential for keeping straight line wire drawing machines running efficiently and producing high-quality wire. By following these maintenance tips, you can extend the lifespan of your machines and ensure consistent performance. Regular cleaning, lubrication, inspection, tension monitoring, calibration, and professional maintenance checks are all key aspects of maintaining these machines. By taking care of your equipment, you can maximize productivity and minimize downtime in your manufacturing operations.

Comparison of Different Straight Line Wire Drawing Machine Models

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. Continuous Wire Drawing Machine is a type of wire drawing machine that is commonly used in the industry due to their efficiency and precision.

There are several different models of straight line wire drawing machines available on the market, each with its own unique features and capabilities. In this article, we will compare some of the most popular models to help you determine which one is best suited for your specific needs.

One of the most important factors to consider when choosing a straight line wire drawing machine is the number of dies it has. The number of dies determines how many times the wire will be drawn through the machine, which in turn affects the final diameter of the wire. Machines with more dies are capable of producing wires with smaller diameters, making them ideal for applications that require fine wires.

Another important factor to consider is the speed at which the machine can operate. The speed of the machine will determine how quickly you can produce wire, which can have a significant impact on your overall production efficiency. Machines with higher speeds are able to produce wire at a faster rate, making them ideal for high-volume production environments.

In addition to the number of dies and the speed of the machine, it is also important to consider the overall build quality and durability of the machine. A well-built machine will be able to withstand the rigors of daily use and provide consistent performance over time. Look for machines that are made from high-quality materials and have a solid construction to ensure long-term reliability.

When comparing different models of straight line wire drawing machines, it is also important to consider the level of automation and control that each machine offers. Some machines come equipped with advanced features such as digital controls and automatic tension adjustment, which can help improve the overall efficiency and accuracy of the wire drawing process.

Ultimately, the best straight line wire drawing machine for your needs will depend on a variety of factors, including the size of wire you need to produce, the volume of production required, and your budget. By carefully considering these factors and comparing different models, you can choose a machine that will help you achieve your production goals efficiently and effectively.

In conclusion, straight line wire drawing machines are an essential tool for the manufacturing industry, allowing companies to produce wires of various sizes and shapes with precision and efficiency. By comparing different models based on factors such as the number of dies, speed, build quality, and level of automation, you can choose a machine that meets your specific needs and helps you achieve your production goals.