Table of Contents

Maintenance Tips for straight line wire drawing machines

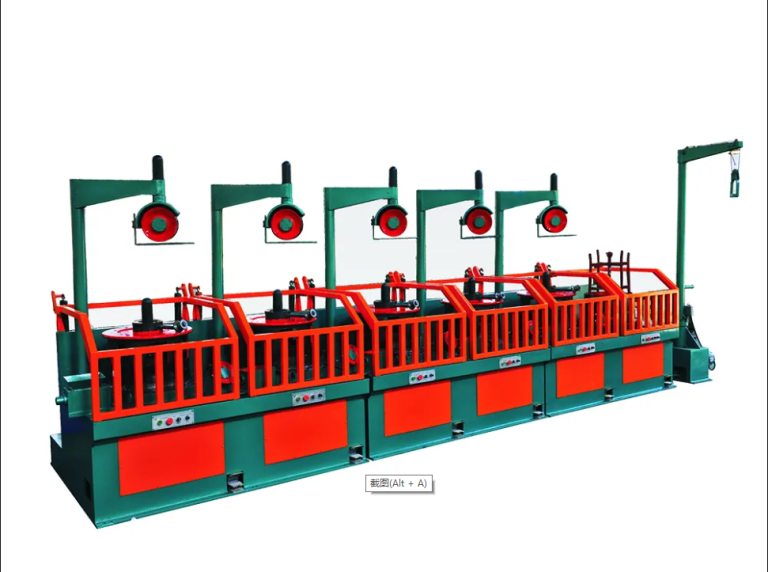

Straight line wire drawing machine is essential equipment in the manufacturing industry for producing wires of various diameters and lengths. These machines are designed to pull a wire through a series of dies to reduce its diameter and improve its surface finish. To ensure the smooth operation and longevity of straight line wire drawing machines, proper maintenance is crucial. In this article, we will discuss some maintenance tips to help you keep your straight line wire drawing machines in top condition.

Regular cleaning of the machine is essential to prevent the buildup of dirt, dust, and debris that can affect its performance. Use a soft brush or cloth to remove any particles from the machine’s surface, dies, and other components. Make sure to clean the wire drawing dies regularly to prevent any blockages that can hinder the wire’s movement through the machine.

Inspect the machine’s components, such as the drive system, bearings, and rollers, for any signs of wear or damage. Replace any worn-out parts immediately to prevent further damage to the machine and ensure its smooth operation. Lubricate the machine’s moving parts regularly to reduce friction and wear, and extend the machine’s lifespan.

Check the tension of the wire regularly to ensure that it is within the recommended range. Adjust the tension as needed to prevent the wire from breaking or getting stuck in the machine. Proper tension is crucial for achieving the desired wire diameter and surface finish.

Monitor the machine’s speed and adjust it as needed to achieve the desired wire drawing rate. Running the machine at the correct speed will help prevent overheating and excessive wear on the components. Make sure to follow the manufacturer’s recommendations for the optimal operating speed of the machine.

Inspect the cooling system of the machine to ensure that it is functioning properly. Proper cooling is essential to prevent overheating of the wire drawing dies and other components. Clean the cooling system regularly to remove any dirt or debris that can clog the system and affect its performance.

Keep a record of the machine’s maintenance schedule and perform routine inspections to identify any potential issues before they escalate. Regular maintenance will help prevent costly repairs and downtime, ensuring that your Dry Type Wire Drawing Machine operates efficiently and reliably.

In conclusion, proper maintenance is essential for keeping straight line wire drawing machines in top condition. Regular cleaning, inspection, lubrication, and adjustment of the machine’s components will help prevent wear and damage, ensuring its smooth operation and longevity. By following these maintenance tips, you can maximize the performance and lifespan of your straight line wire drawing machine, ultimately improving your manufacturing process and product quality.

Advantages of Using Straight Line Wire Drawing Machines

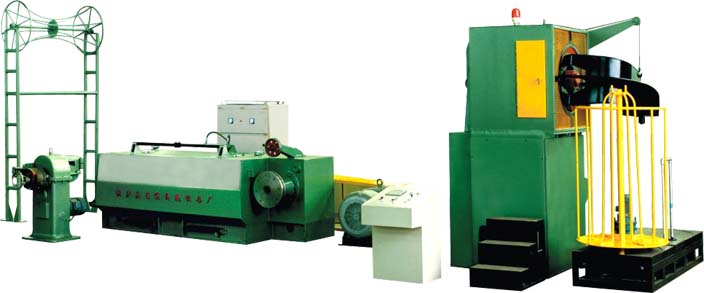

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to fencing. One type of Continuous Wire Drawing Machine that is commonly used in this process is the straight line wire drawing machine.

Straight line wire drawing machines are designed to pull the wire through a series of dies in a straight line, without any bending or twisting. This type of machine offers several advantages over other types of wire drawing machines, making it a popular choice for many manufacturers.

One of the main advantages of using a straight line wire drawing machine is its ability to produce wires with a high level of precision. Because the wire is pulled through the dies in a straight line, there is minimal distortion or stretching of the wire, resulting in a more uniform diameter and smoother surface finish. This level of precision is essential for applications where the wire needs to meet strict tolerances or specifications.

In addition to precision, straight line wire drawing machines also offer increased productivity. These machines are capable of drawing wire at higher speeds than other types of wire drawing machines, allowing manufacturers to produce more wire in less time. This increased productivity can help manufacturers meet tight production deadlines and keep up with high demand for their products.

Another advantage of using a straight line wire drawing machine is its versatility. These machines can be used to draw a wide range of wire sizes and materials, making them suitable for a variety of applications. Whether you need to produce thin copper wire for electrical applications or thick steel wire for industrial purposes, a straight line wire drawing machine can handle the job.

Furthermore, straight line wire drawing machines are known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, making them a long-lasting investment for manufacturers. With proper maintenance and care, a straight line wire drawing machine can provide years of reliable service, helping manufacturers reduce downtime and increase production efficiency.

In conclusion, straight line wire drawing machines offer several advantages that make them a popular choice for manufacturers in the wire drawing industry. From precision and productivity to versatility and durability, these machines provide the capabilities needed to produce high-quality wire for a wide range of applications. If you are in the market for a wire drawing machine, consider investing in a straight line wire drawing machine to take advantage of these benefits and improve your manufacturing process.