Table of Contents

Exploring The Benefits of Using straight line wire drawing machine in China

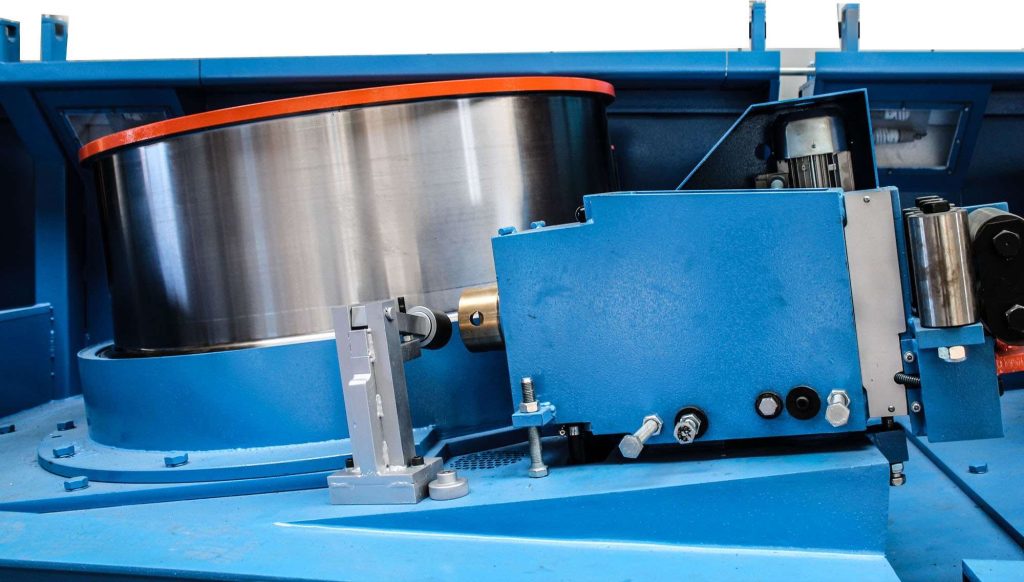

Wire drawing is a process used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to construction materials. In China, the use of straight line wire drawing machines has become increasingly popular due to their efficiency and precision.

One of the key benefits of using a straight line wire drawing machine in China is its ability to produce wires with consistent diameter and smooth surface finish. This is crucial for ensuring the quality and performance of the final product, as any variations in diameter or surface imperfections can affect the wire’s strength and conductivity. By using a straight line wire drawing machine, manufacturers can achieve tight tolerances and high-quality finishes, resulting in superior products that meet the strict standards of the industry.

Another advantage of using a straight line wire drawing machine in China is its high production efficiency. These machines are designed to operate at high speeds, allowing manufacturers to process large quantities of wire in a short amount of time. This not only increases productivity but also reduces production costs, as fewer resources are required to produce the same amount of wire. Additionally, the automated nature of these machines minimizes the need for manual labor, further streamlining the production process and improving overall efficiency.

In addition to efficiency and quality, Continuous Wire Drawing Machine in China offer versatility in terms of wire size and material. These machines can accommodate a wide range of wire diameters and materials, including steel, copper, and aluminum. This flexibility allows manufacturers to produce wires for various applications, from thin electrical wires to thick cables used in construction. By using a single machine to process different types of wire, manufacturers can save time and resources, making their operations more cost-effective and competitive in the market.

Furthermore, straight line wire drawing machines in China are known for their durability and reliability. These machines are built to withstand the rigors of continuous operation, ensuring consistent performance and minimal downtime. This reliability is crucial for meeting production deadlines and maintaining customer satisfaction. Additionally, many manufacturers offer maintenance services and technical support for their machines, further enhancing their longevity and performance.

Overall, the benefits of using a straight line wire drawing machine in China are clear. From improved quality and efficiency to versatility and reliability, these machines offer a range of advantages for manufacturers in the wire industry. By investing in a high-quality wire drawing machine, manufacturers can enhance their production capabilities, reduce costs, and stay competitive in the global market. With the growing demand for high-quality wires in various industries, the use of straight line wire drawing machines in China is expected to continue to rise in the coming years.

How to Choose the Right Straight Line Wire Drawing Machine Supplier in China

When it comes to choosing the right Straight Line Wire Drawing Machine For Low Carbon Steel Wire supplier in China, there are several factors that you need to consider. With the growing demand for wire drawing machines in various industries, it is important to find a reliable supplier that can provide high-quality machines at competitive prices.

One of the first things to consider when choosing a straight line wire drawing machine supplier in China is the reputation of the company. Look for suppliers that have a good track record of delivering quality machines to their customers. You can check online reviews and testimonials from previous clients to get an idea of the supplier’s reputation.

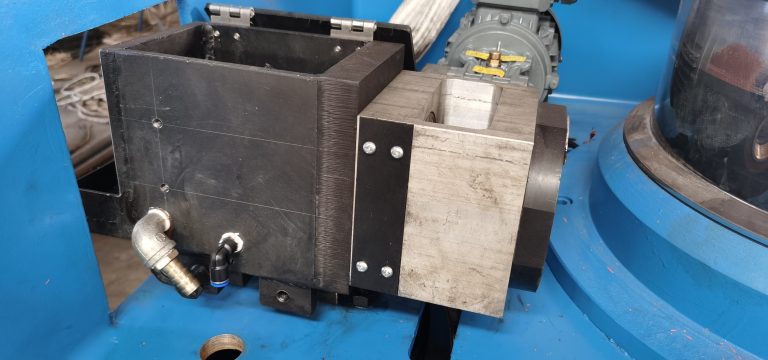

Another important factor to consider is the quality of the machines that the supplier offers. Make sure to ask for samples or visit the supplier’s factory to see the machines in person. Look for machines that are well-built, durable, and can produce high-quality wire products.

In addition to quality, you should also consider the price of the machines. While it is important to find a supplier that offers competitive prices, be wary of suppliers that offer machines at significantly lower prices than their competitors. This could be a red flag that the machines are of lower quality.

It is also important to consider the after-sales service that the supplier offers. Look for suppliers that provide technical support, training, and maintenance services for their machines. This will ensure that you can get help if you encounter any issues with the machines in the future.

When choosing a straight line wire drawing machine supplier in China, it is also important to consider the supplier’s experience and expertise in the industry. Look for suppliers that have been in business for a long time and have a deep understanding of wire drawing technology. This will ensure that you are getting machines that are up-to-date and meet industry standards.

Lastly, consider the supplier’s location and logistics capabilities. Choose a supplier that is located close to your business or has good transportation links to ensure that you can receive your machines in a timely manner. Make sure to inquire about the supplier’s shipping and delivery options to avoid any delays.

In conclusion, choosing the right straight line wire drawing machine supplier in China requires careful consideration of several factors. Look for a supplier with a good reputation, high-quality machines, competitive prices, excellent after-sales service, industry experience, and good logistics capabilities. By taking the time to research and evaluate different suppliers, you can find a reliable partner that can provide you with the machines you need to meet your wire drawing needs.