Understand the Benefits of Using a Steel Brush Descaler for Wire Drawing Process

The wire drawing process is a critical step in the production of various types of wire, including steel, aluminum, and copper. This process involves pulling a metal rod or wire through a series of dies to reduce its diameter and increase its length. However, before the wire can be drawn, it must be properly cleaned and descaled to ensure a smooth and efficient drawing process.

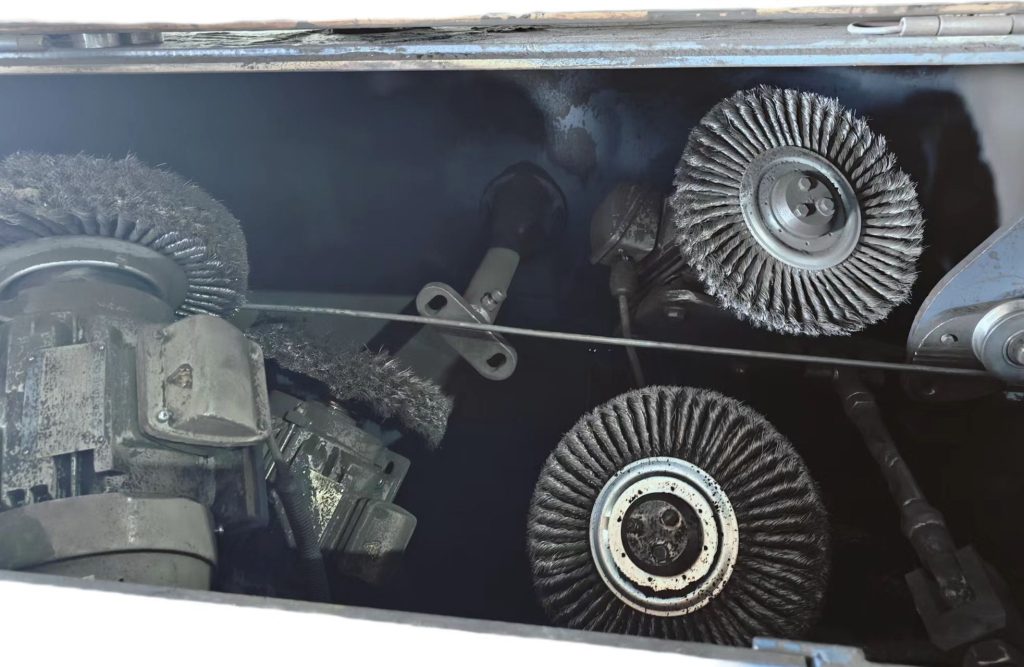

One of the most effective tools for descaling wire is a steel brush descaler. This type of descaler is specifically designed to remove scale, rust, and other surface contaminants from metal wire, making it an essential tool for wire drawing operations. There are several benefits to using a steel brush descaler for the wire drawing process.

First and foremost, a steel Wire Brush Descaler Machine is highly effective at removing scale and other surface contaminants from metal wire. This is important because any residual scale or rust on the surface of the wire can cause damage to the dies during the drawing process, leading to increased downtime and maintenance costs. By using a steel brush descaler, wire manufacturers can ensure that their wire is clean and free from surface contaminants, resulting in a smoother and more efficient drawing process.

In addition to its effectiveness, a steel brush descaler is also highly durable and long-lasting. The bristles of the steel brush are made from high-quality steel, which is able to withstand the rigors of descaling metal wire on a daily basis. This durability ensures that the descaler will continue to perform effectively over time, reducing the need for frequent replacement and maintenance.

Furthermore, a steel brush descaler is also versatile and can be used on a wide range of wire sizes and materials. Whether you are drawing steel, aluminum, or copper wire, a steel brush descaler can effectively remove scale and surface contaminants from the wire, making it a versatile tool for wire manufacturers.

Another benefit of using a steel brush descaler for the wire drawing process is its ease of use. The descaler can be easily mounted onto existing wire drawing equipment, allowing for seamless integration into the production process. Additionally, the descaler is simple to operate, requiring minimal training for operators. This ease of use ensures that the descaling process does not add unnecessary complexity to the wire drawing operation.

Finally, using a steel brush descaler for the wire drawing process can also lead to cost savings for wire manufacturers. By effectively removing scale and surface contaminants from the wire, the descaler helps to prolong the life of the drawing dies, reducing the need for frequent die replacements and maintenance. Additionally, the smooth and clean surface of the wire produced by the descaler can lead to improved drawing efficiency, resulting in higher productivity and reduced energy consumption.

In conclusion, the use of a steel brush descaler for the wire drawing process offers several benefits for wire manufacturers. From its effectiveness at removing scale and surface contaminants to its durability, versatility, ease of use, and potential cost savings, a steel brush descaler is an essential tool for ensuring a smooth and efficient wire drawing operation. By investing in a high-quality steel brush descaler, wire manufacturers can improve the quality of their wire products and enhance the overall efficiency of their production process.