Table of Contents

Top Tips for Properly Maintaining and Using a Steel Brush Descaler

Steel brush descalers are essential tools for removing rust, scale, and other debris from metal surfaces. Whether you are a professional welder, metal fabricator, or simply a DIY enthusiast, having a high-quality steel brush descaler in your arsenal can make your work easier and more efficient. In this article, we will discuss some top tips for properly maintaining and using a steel brush descaler to ensure optimal performance and longevity.

First and foremost, it is important to choose the right type of steel brush descaler for your specific needs. There are various types of steel brush descalers available on the market, including handheld models, bench-mounted models, and even pneumatic models. Consider the size of the surfaces you will be working on, as well as the level of rust or scale you need to remove, when selecting a steel brush descaler.

Once you have chosen the right steel brush descaler for your needs, it is crucial to properly maintain it to ensure it continues to perform at its best. Regularly inspect the brush for any signs of wear or damage, and replace it if necessary. Keep the brush clean and free of debris, as buildup can affect its performance. Additionally, lubricate any moving parts as needed to prevent rust and ensure smooth operation.

When using a steel brush descaler, it is important to follow proper safety precautions to prevent injury. Always wear appropriate personal protective equipment, such as gloves, safety goggles, and a dust mask, to protect yourself from flying debris and harmful fumes. Make sure the work area is well-ventilated to prevent the buildup of fumes and dust. And never operate a steel brush descaler near flammable materials or in wet conditions.

When using a steel brush descaler, it is important to use the correct technique to achieve the best results. Start by securely clamping the workpiece in place to prevent movement during the descaling process. Hold the steel brush descaler at a slight angle to the surface being cleaned, and move it in a back-and-forth motion to remove rust and scale effectively. Avoid applying too much pressure, as this can damage the surface being cleaned and wear out the brush prematurely.

After using a steel brush descaler, it is important to properly clean and store it to ensure its longevity. Remove any debris or buildup from the brush, and wipe it down with a clean cloth to prevent rust. Store the steel brush descaler in a dry, cool place away from moisture and direct sunlight. Consider investing in a protective case or cover to prevent damage during storage.

In conclusion, steel brush descalers are valuable tools for removing rust, scale, and other debris from metal surfaces. By choosing the right type of descaler, properly maintaining it, following safety precautions, using the correct technique, and cleaning and storing it properly, you can ensure that your steel brush descaler performs at its best for years to come. Whether you are a professional tradesperson or a hobbyist, a steel brush descaler is a worthwhile investment for your workshop.

Benefits of Using Steel Brush Descaler for Industrial Equipment Maintenance

Steel brush descalers are essential tools for maintaining industrial equipment and machinery. These powerful tools are designed to remove rust, scale, and other debris from metal surfaces, ensuring that equipment operates efficiently and safely. In this article, we will explore the benefits of using a steel brush descaler for industrial equipment maintenance.

One of the primary benefits of using a steel brush descaler is its ability to effectively remove rust and scale from metal surfaces. Over time, metal equipment can become corroded and degraded due to exposure to moisture and other environmental factors. Rust and scale can weaken metal structures, leading to equipment failure and safety hazards. By using a steel brush descaler, you can easily remove these corrosive materials and restore metal surfaces to their original condition.

In addition to removing rust and scale,Mechanical Wire Descaler for wire drawing process are also effective at cleaning metal surfaces. Dirt, grease, and other contaminants can build up on industrial equipment, affecting its performance and longevity. A steel brush descaler can quickly and efficiently remove these contaminants, leaving metal surfaces clean and ready for use. This not only improves the appearance of equipment but also helps to prevent corrosion and other damage.

Another benefit of using a steel brush descaler is its versatility. These tools come in a variety of sizes and configurations, making them suitable for a wide range of industrial applications. Whether you need to clean large machinery or small components, there is a steel brush descaler that is right for the job. Additionally, steel brush descalers can be used on a variety of metal surfaces, including steel, aluminum, and copper, making them a versatile tool for industrial maintenance.

Using a steel brush descaler is also a cost-effective way to maintain industrial equipment. Regular maintenance and cleaning can help to extend the life of machinery, reducing the need for costly repairs or replacements. By investing in a steel brush descaler, you can keep your equipment in top condition and avoid the expenses associated with neglecting maintenance.

Furthermore, using a steel brush descaler is a safe and environmentally friendly way to clean metal surfaces. Unlike harsh chemicals and abrasive materials, steel brush descalers do not produce harmful fumes or residues that can be harmful to workers or the environment. This makes them a preferred choice for industrial maintenance professionals who are committed to safety and sustainability.

In conclusion, steel brush descalers are essential tools for maintaining industrial equipment and machinery. These versatile tools are effective at removing rust, scale, and other contaminants from metal surfaces, improving equipment performance and longevity. By investing in a steel brush descaler, you can keep your industrial equipment in top condition, reduce maintenance costs, and promote a safe and environmentally friendly work environment.

How to Choose the Right Steel Brush Descaler for Your Needs

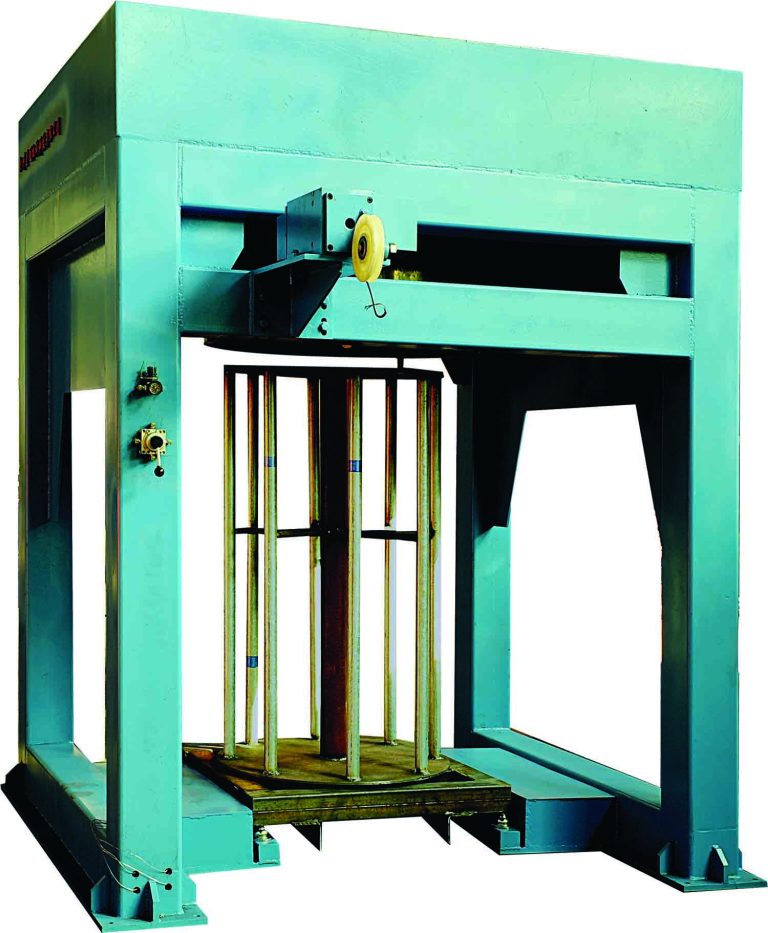

When it comes to removing rust, scale, and other debris from metal surfaces, a Mechanical brush descaler is an essential tool. These powerful machines use abrasive brushes to quickly and efficiently clean metal surfaces, making them ideal for a wide range of applications, from industrial cleaning to automotive restoration. If you’re in the market for a steel brush descaler, there are a few key factors to consider to ensure you choose the right machine for your needs.

One of the first things to consider when choosing a steel brush descaler is the size and power of the machine. Steel brush descalers come in a variety of sizes, from small handheld models to large industrial machines. The size of the machine you choose will depend on the size of the surfaces you need to clean and the amount of power you need to remove debris effectively. For smaller jobs, a handheld or portable steel brush descaler may be sufficient, while larger industrial applications may require a larger, more powerful machine.

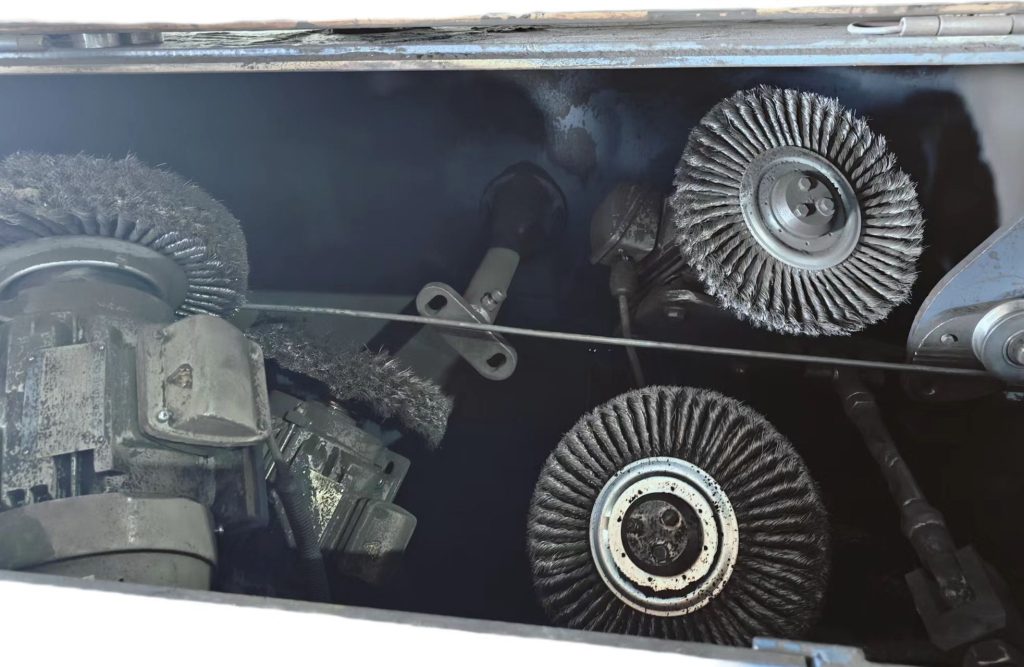

Another important factor to consider when choosing a steel brush descaler is the type of brushes it uses. Steel brush descalers come with a variety of brush types, including wire brushes, nylon brushes, and abrasive brushes. The type of brush you choose will depend on the type of surface you need to clean and the level of abrasiveness required. Wire brushes are ideal for removing heavy rust and scale from metal surfaces, while nylon brushes are gentler and are suitable for more delicate surfaces. Abrasive brushes are the most powerful option and are ideal for removing tough debris from metal surfaces.

In addition to size and brush type, it’s also important to consider the speed and power of the steel brush descaler. The speed of the machine will determine how quickly it can clean a surface, while the power will determine how effectively it can remove debris. Higher speeds and power levels are generally better for larger, more stubborn debris, while lower speeds and power levels are suitable for smaller, less stubborn debris. It’s important to choose a machine with the right balance of speed and power for your specific needs to ensure efficient and effective cleaning.

When choosing a steel brush descaler, it’s also important to consider the durability and reliability of the machine. Look for a machine made from high-quality materials that can withstand heavy use and provide consistent performance over time. It’s also a good idea to choose a machine from a reputable manufacturer with a track record of producing reliable, high-quality products. Reading reviews and testimonials from other customers can also help you determine the durability and reliability of a particular machine.

In conclusion, choosing the right steel brush descaler is essential for effective metal surface cleaning. Consider factors such as size, brush type, speed, power, durability, and reliability when choosing a machine to ensure you get the best results for your specific needs. By taking the time to research and compare different options, you can find a steel brush descaler that meets your requirements and helps you achieve clean, debris-free metal surfaces.